Method of using camera to carry out controlling automatic alignment for printing machine

An automatic registration and camera technology, which is applied to the general parts of printing machinery, printing machines, printing, etc., can solve the problems of high scrap rate and poor control of printed matter printing quality, achieve low paper loss, save raw materials, and register high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

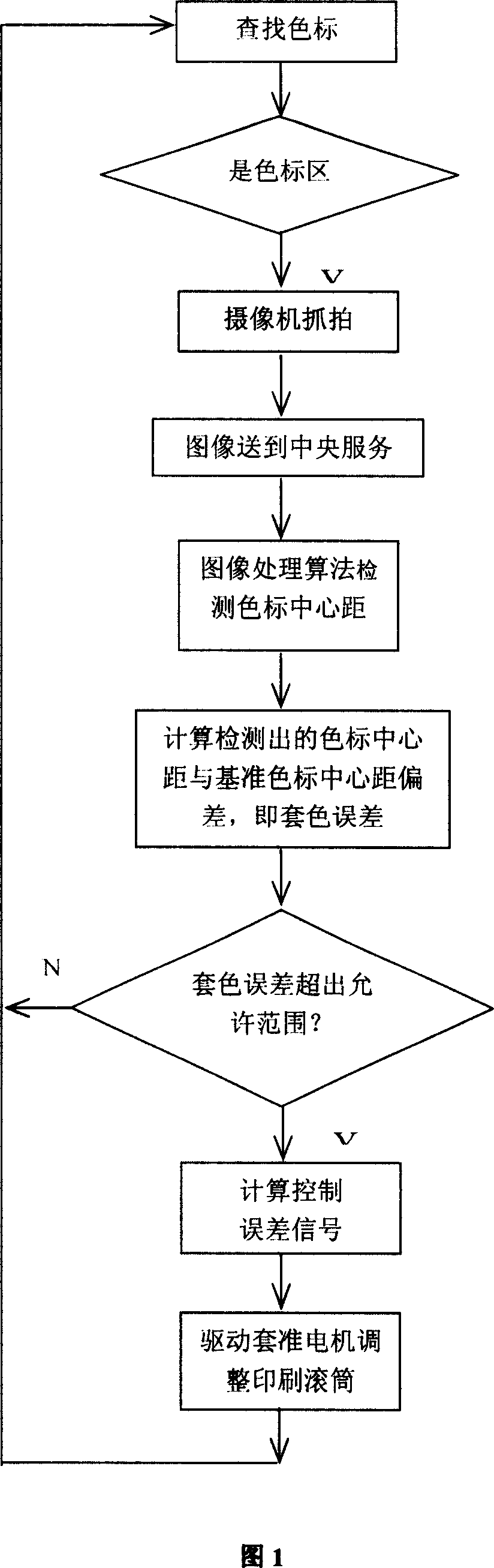

[0037] Include the following steps:

[0038] 1. When making a plate, a color mark group specially used to detect color registration errors is printed on the outside of each color printing pattern at the same time;

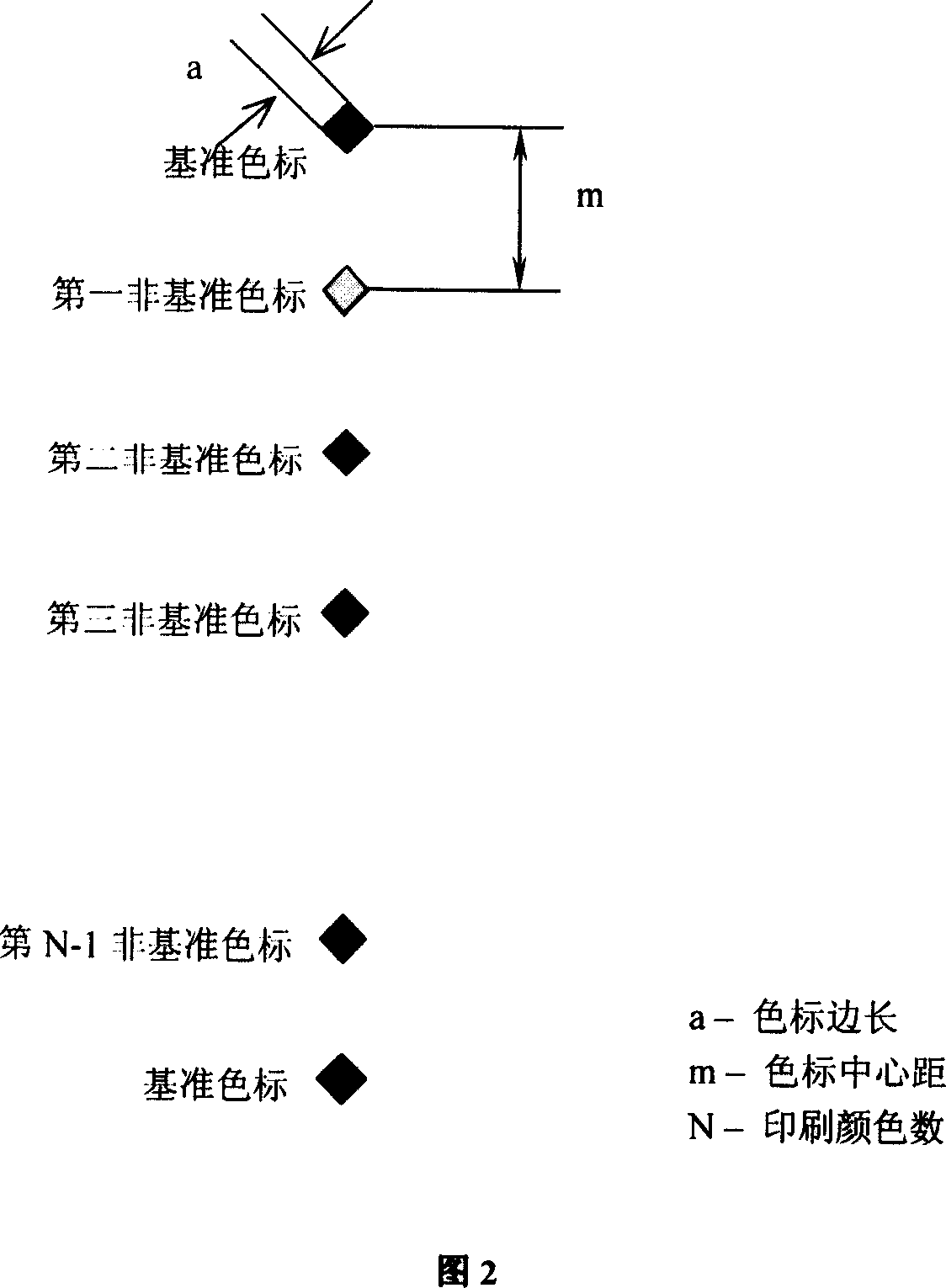

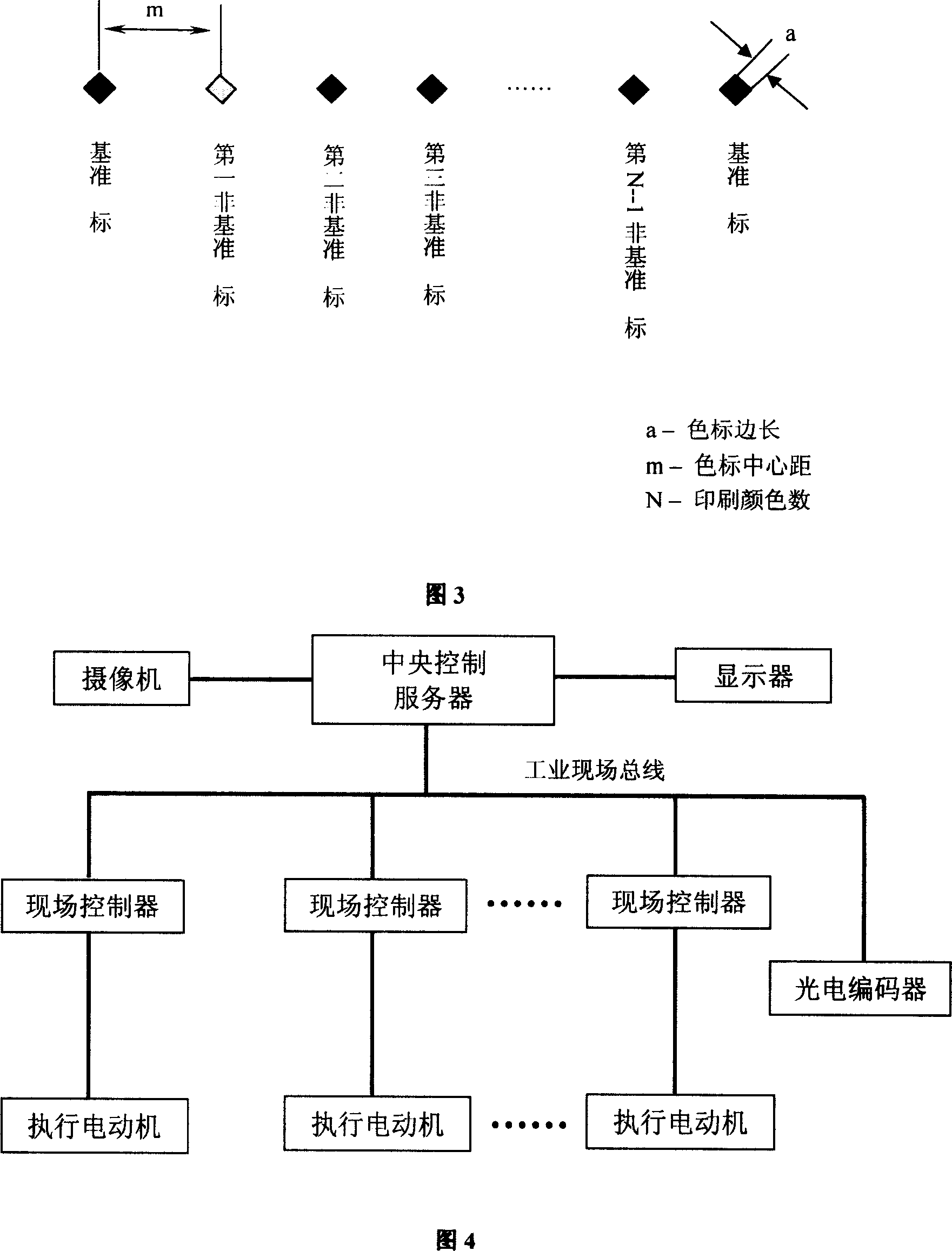

[0039] As shown in accompanying drawings 2 and 3, the color code group is composed of a group of rhombus-shaped color marks, the color code can be arranged at any position on the printing plate, and other patterns can appear around the color code group;

[0040] The side length a of the color code is 0.3-3 mm, and the distance m between the color code and the center of the color code is 3-15 mm. The color codes can be arranged in the circumferential direction of the printing plate, or in the axial direction of the printing plate; The number of color marks is N+1, where N is the number of printing colors, such as four-color printing, the printed color mark group includes 5 color marks.

[0041] The color scales at the front and the back of the color scale group are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com