Expansion type fire retardant material

A kind of flame retardant material and intumescent technology, which is applied in the field of flame retardant materials, can solve the problems of poor compatibility between flame retardant materials and polyolefins, environmental pollution, and large addition amount, and achieve good compatibility, environmental friendliness, and high addition amount small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

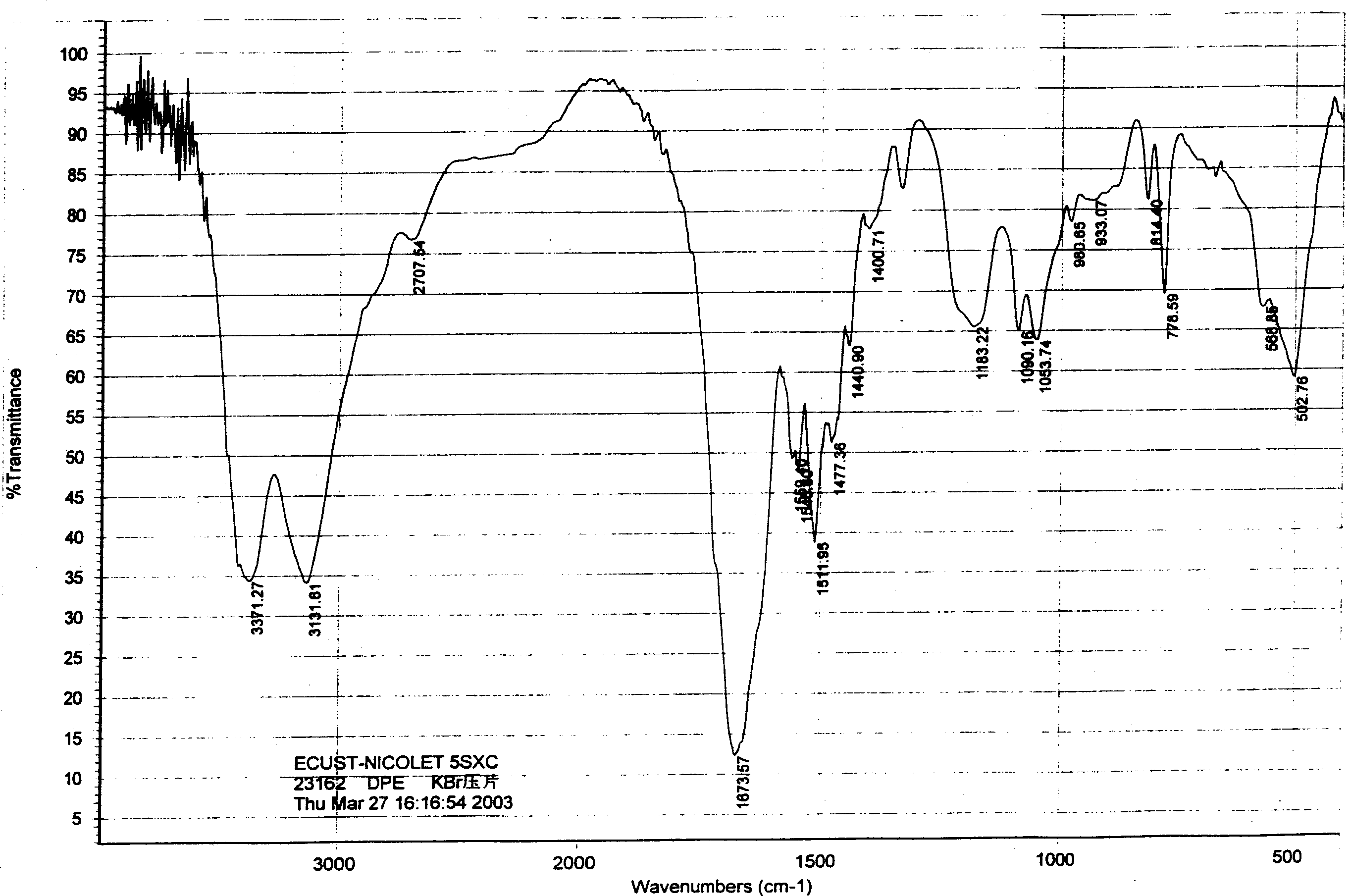

[0028] Add 19g of pentaerythritol, 2.5g of water, and 10g of phosphorus pentoxide into a three-neck flask, place in an oil bath at 75°C, and stir vigorously for 6 hours; add 12.6g of melamine, and react at 160°C for 2 hours. After the reaction was finished, the obtained product was washed with a large amount of deionized water until it was nearly neutral. After the polypropylene is plasticized on a two-roller plastic mixer, add 20% flame retardant, knead at 160°C for 10 minutes to make it evenly mixed, and hydraulically form it on a hot press at 185°C. The flame retardancy of the flame retardant and the mechanical properties of the prepared samples were determined. The test result is that the oxygen index is 23, the horizontal combustion test is FH-2, and the tensile strength is 8.2MPa. Its infrared spectrum is as figure 1 shown. Its specific structure is as follows: Among them, 3371.27cm -1 It is N-H structure; 3131.27cm -1 It is -OH structure; 2707.54cm -1 It is an ali...

Embodiment 2

[0030] Add 18g of dipentaerythritol, 5g of water, and 10g of phosphorus pentoxide into a three-neck flask, place in an oil bath at 90°C, and stir vigorously for 4 hours; add 12.6g of melamine, and react at 160°C for 2 hours. After the reaction was finished, the obtained product was washed with a large amount of deionized water until it was nearly neutral. After the polypropylene is plasticized on a two-roller plastic mixer, add 20% flame retardant, knead at 160°C for 10 minutes to make it evenly mixed, and hydraulically form it on a hot press at 185°C. The flame retardancy of the flame retardant and the mechanical properties of the prepared samples were determined. The test result is that the oxygen index is 26, the horizontal combustion test is FH-2, and the tensile strength is 7.8MPa.

Embodiment 3

[0032] Add 13g of tripentaerythritol, 10.1g of water, and 20g of phosphorus pentoxide into a three-neck flask, place in an oil bath at 105°C, and stir vigorously for 4 hours; add 18.9g of melamine, and react at 170°C for 2 hours. After the reaction was finished, the obtained product was washed with a large amount of deionized water until it was nearly neutral. After the polypropylene weighed in proportion is plasticized on a two-roller plastic mixer, add a flame retardant and knead at 185°C for 10 minutes to make it evenly mixed, then hydraulically form it on a hot press at 185°C, and make a sample with a universal prototype machine . The flame retardancy of the flame retardant and the mechanical properties of the prepared samples were determined. The test result is that the oxygen index is 28, the horizontal combustion test is FH-2, and the tensile strength is 7.5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com