Perovskite/polymer composite luminescent material and preparation method thereof

A technology of luminescent materials and polymers, applied in the directions of luminescent materials, chemical instruments and methods, optics, etc., can solve problems such as inapplicability in the field of luminescence, and achieve the effects of easy adjustment of void size, high luminous intensity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

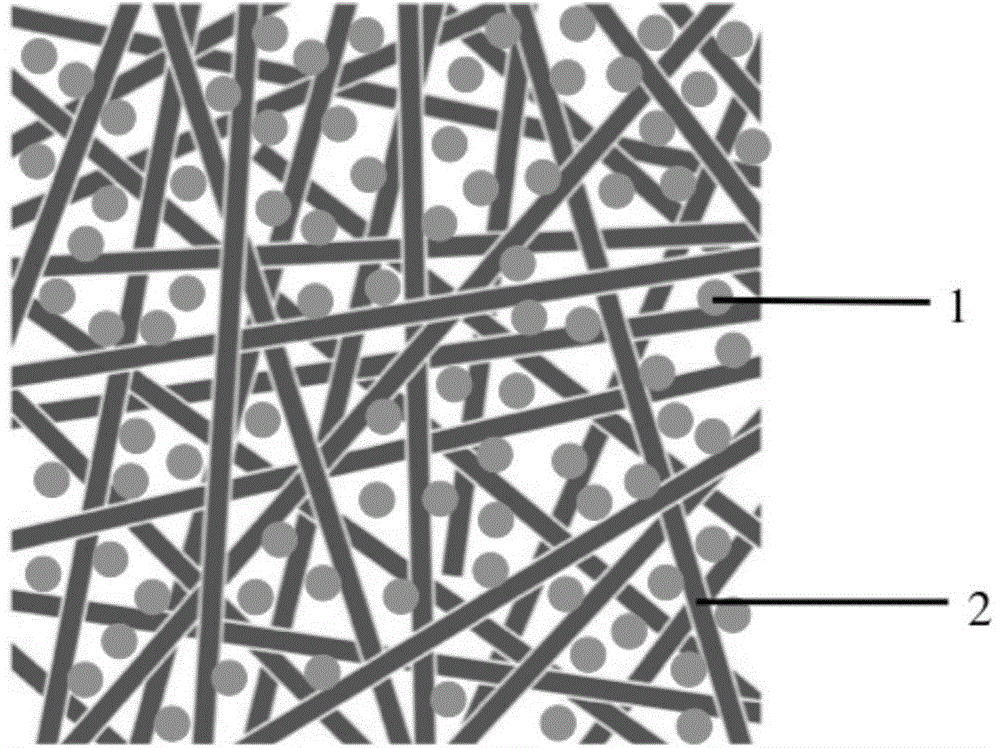

[0031] The preparation method of the perovskite / polymer composite luminescent material of the present invention comprises the following steps:

[0032] (1) Dissolve the polymer in an organic solvent, control the mass ratio of the polymer to the organic solvent to 1: (1-50), and mix ultrasonically for 12 hours. After the polymer is completely dissolved, a uniform and viscous polymer solution is obtained. , adding additives to the polymer solution, controlling the mass ratio: polymer: additive = 1: (0-0.5), ultrasonically mixing for 1-3 hours, and mixing uniformly to obtain the first solution; the organic solvent is N, N-dimethylformamide (DMF), dimethyl sulfoxide (DMSO), trimethyl phosphate (TMP), triethyl phosphate (TEP), N-methylpyrrolidone (NMP) or dimethyl ethyl Any one of amides (DMAc), and the additive is any one of polyvinylpyrrolidone (PVP) or polyethylene glycol (PEG);

[0033] (2) mix inorganic halide salt with organic ammonium halide salt powder, control molar ratio...

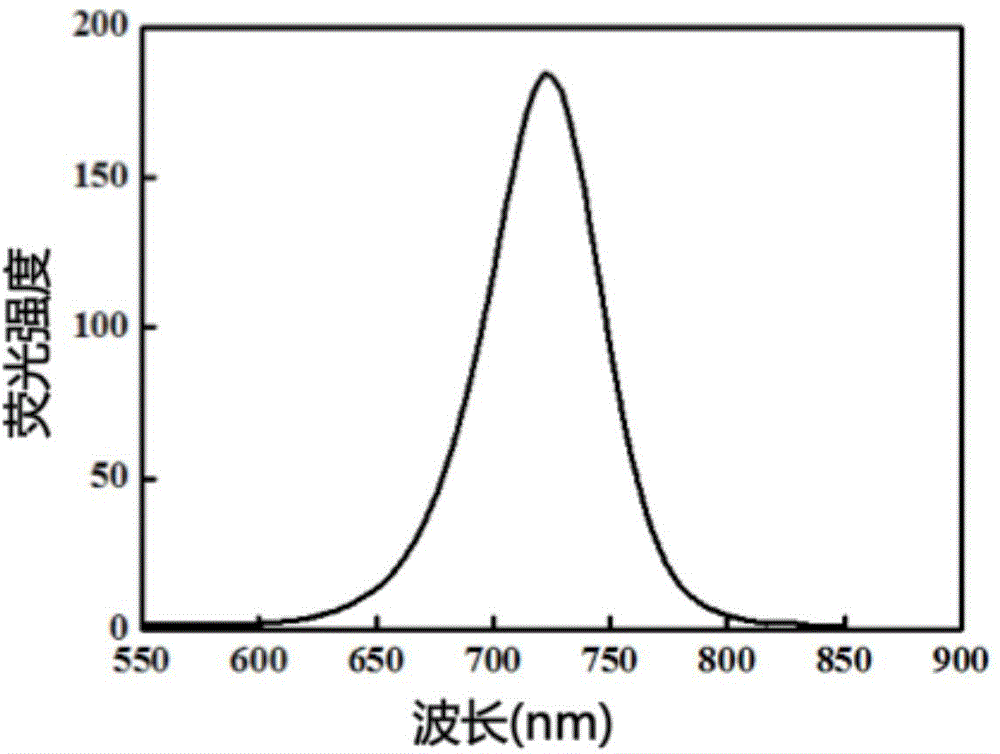

Embodiment 1

[0040] (1) The polymer is dissolved in an organic solvent, and the mass ratio is controlled to be: polymer: organic solvent=1:5, ultrasonically mixed for 12 hours, and after the polymer is completely dissolved, a uniform and viscous polymer solution is obtained, which is prepared in the above-mentioned Add additives to the polymer solution, and control the mass percentage concentration to be: polymer solution: additive = 1:0, ultrasonically mix for 1 h, mix evenly, and the obtained solution is used as the first solution. The polymer is polyvinyl acetate (PVAc); the organic solvent is N,N-dimethylformamide (DMF).

[0041] (2) mix the inorganic halide salt with the organic ammonium halide salt powder, the control molar ratio is: inorganic halide salt:organic ammonium halide salt=1:1, then add the organic solvent, the control mass ratio is: organic solvent:inorganic halide Compound salt=1:0.01, after mixing, ultrasonic treatment was carried out, and after ultrasonic treatment for...

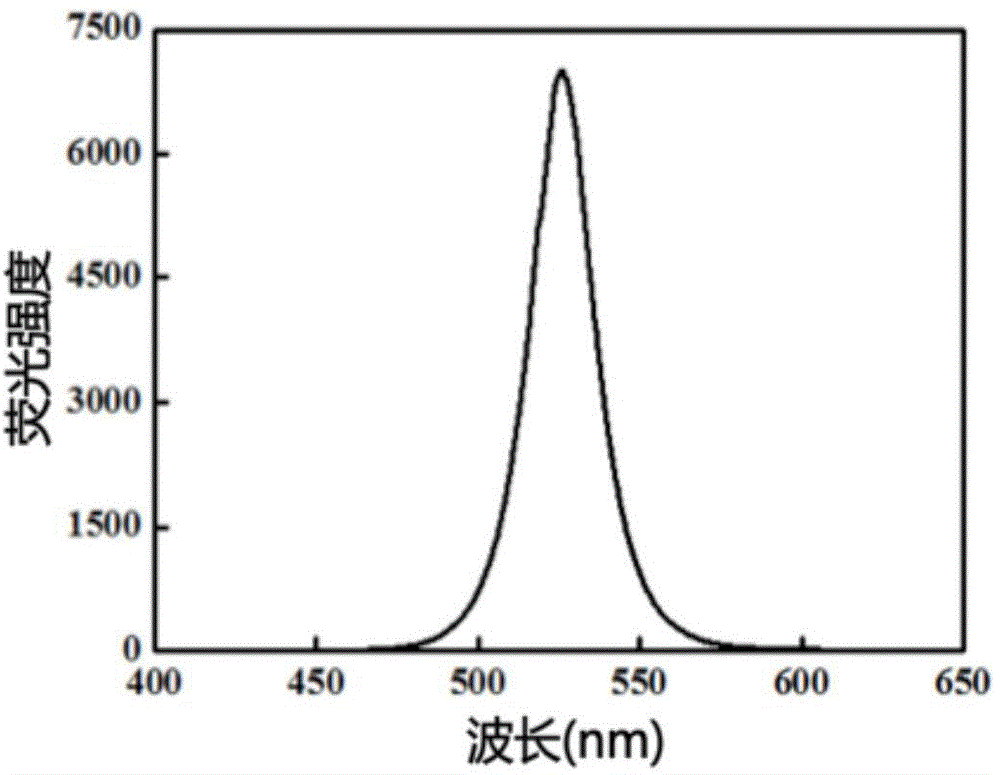

Embodiment 2

[0045] (1) The polymer is dissolved in an organic solvent, and the mass ratio is controlled to be: polymer: organic solvent=1:10, ultrasonically mixed for 12 hours, and after the polymer is completely dissolved, a uniform and viscous polymer solution is obtained, which is prepared in the above-mentioned Add additives to the polymer solution, control the mass ratio: polymer solution: additive = 1:0.1, ultrasonically mix for 2 hours, mix evenly, and the obtained solution is used as the first solution. The polymer is cellulose acetate (CA); the additive is polyvinylpyrrolidone (PVP); the organic solvent is dimethylsulfoxide (DMSO).

[0046] (2) mix the inorganic halide salt with the organic ammonium halide salt powder, the control molar ratio is: inorganic halide salt:organic ammonium halide salt=1:1.5, then add the organic solvent, the control mass ratio is: organic solvent:inorganic halogenated Compound salt=1:(0.02), carry out sonication after mixing, after 15 minutes of sonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence wavelength | aaaaa | aaaaa |

| fluorescence wavelength | aaaaa | aaaaa |

| fluorescence wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com