Coal seam hydraulic punching simulation experiment method

A technology of hydraulic punching and simulation experiments, applied in teaching models, earthwork drilling, mining equipment, etc., to achieve the effect of reliable experimental equipment and experimental methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

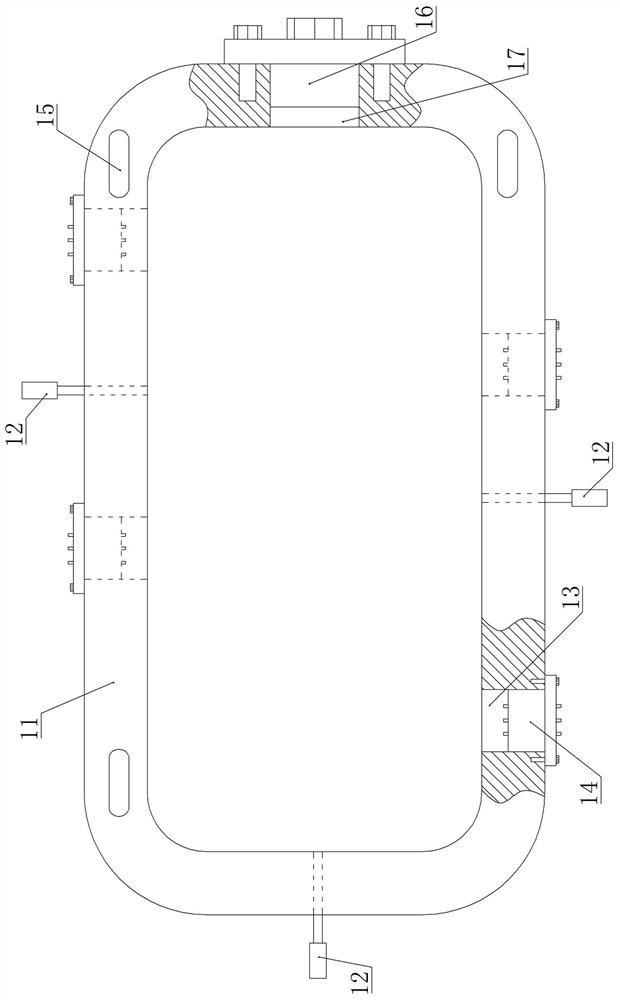

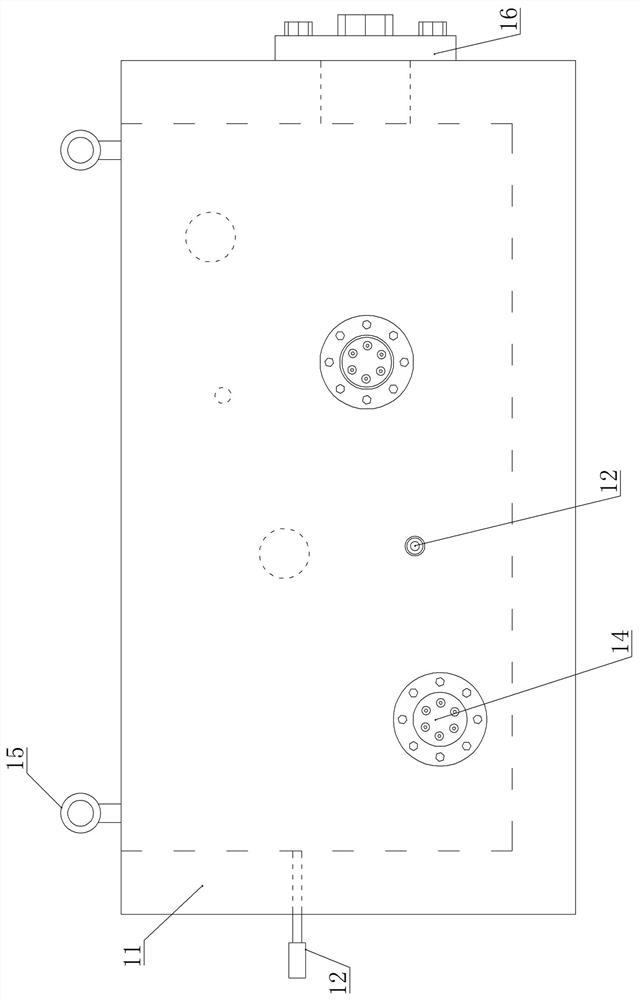

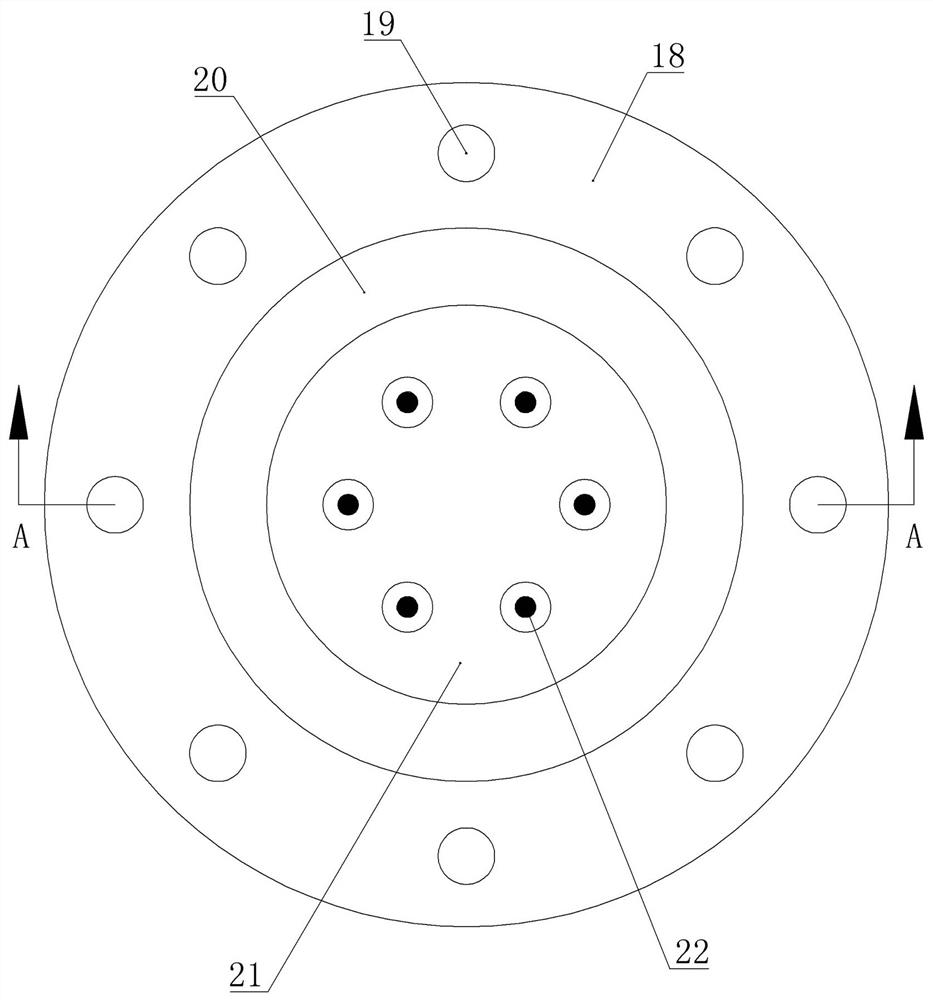

[0042] Embodiment one, see Figure 1-12 , the coal seam hydraulic punching simulation experiment method, the method adopts the coal seam hydraulic punching simulation experiment device, the device includes a coal storage cylinder, a coal pressing column head and a pressure mechanism;

[0043] The two ends of the coal storage cylinder are respectively provided with an air-inflating pipe and a coal drilling hole communicating with the inside, and the coal drilling hole is used for drilling and punching equipment to enter the entrance of the coal storage cylinder, and the coal drilling hole is The plug is equipped with a sealing end cover, and the sealing end cover is fixed on the coal storage cylinder body by bolts. On both sides of the coal storage cylinder body, there are gas-filling tubes and monitoring through-holes connected with the interior. Each gas-filling tube is used as a simulated coal seam. The inlet for vacuuming and injecting experimental gas, each monitoring thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com