Cement base material permanent load composite corrosion test instrument

A cement-based material and corrosion test technology, which is applied in the direction of material inspection products, using stable tension/pressure to test the strength of materials, etc., can solve the problems of low control accuracy, inability to be used in ballast tests, complex structures, etc., to achieve Simple operation, simple load application and control, and the effect of reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

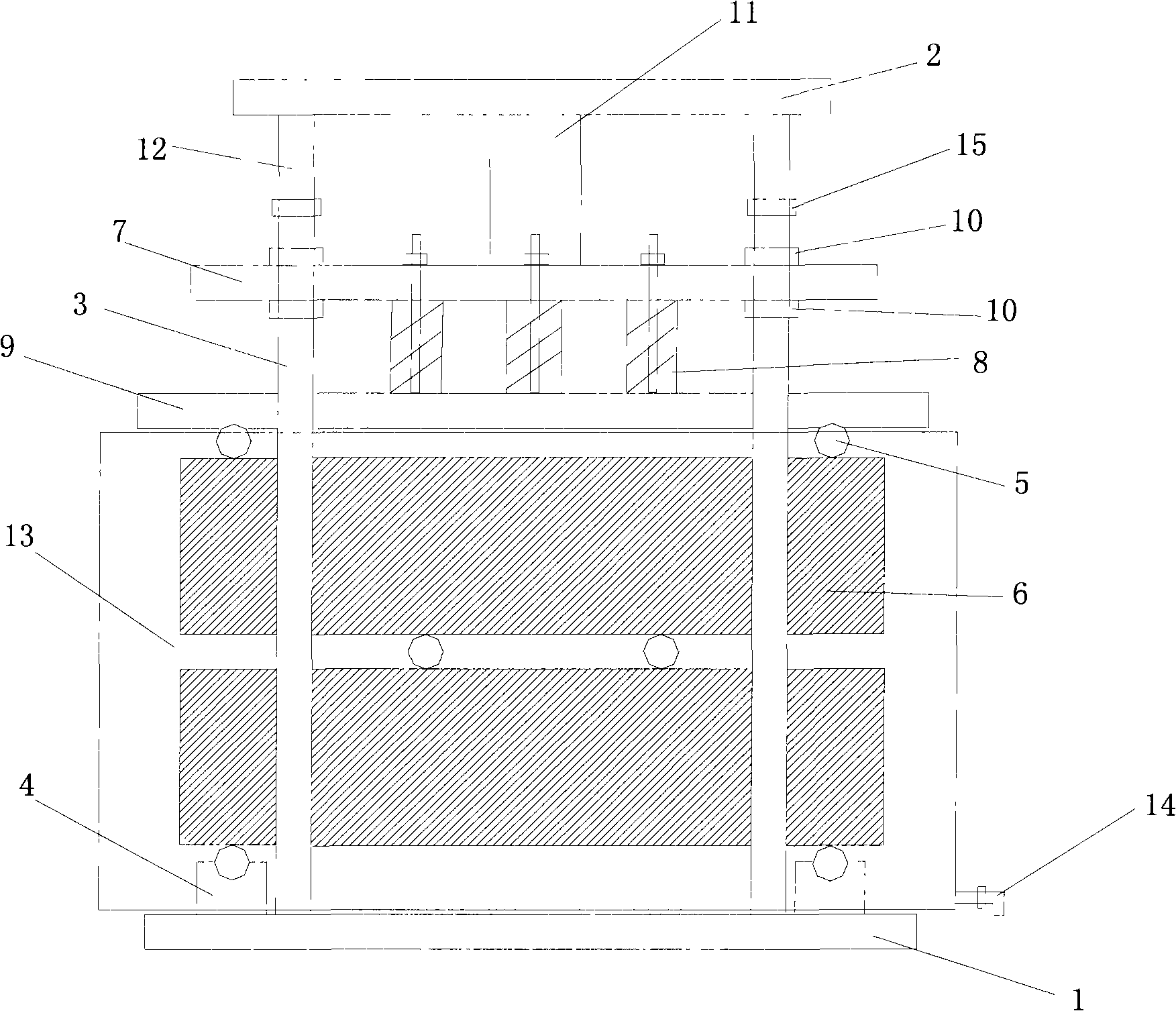

[0016] The device comprises a base plate 1, a pressing plate 7 is arranged directly above the base plate 1, a supporting column 3 is connected between the base plate 1 and the pressing plate 7, one end of the supporting column 3 is fixed on the base plate 1, and the other end is provided with a screw thread and runs through the pressing plate 7; The supporting column 3 is provided with two nuts 10 matched with threads, and the two nuts 10 are located on the upper and lower sides of the pressing plate 7; Two test pieces 6 are clamped between the base plate 1 .

[0017] A jack 11 is provided at the middle part of the upper side of the pressing plate 7 , and the upper side of the jack 11 is in contact with the upper top plate 2 . The lower side of the upper top plate 2 is provided with a connecting rod 12, and the connecting rod 12 and the support column 3 are connected by bolts 15. A water tank 13 is provided between the splint 9 and the bottom plate 1 , and a water outlet valv...

Embodiment 2

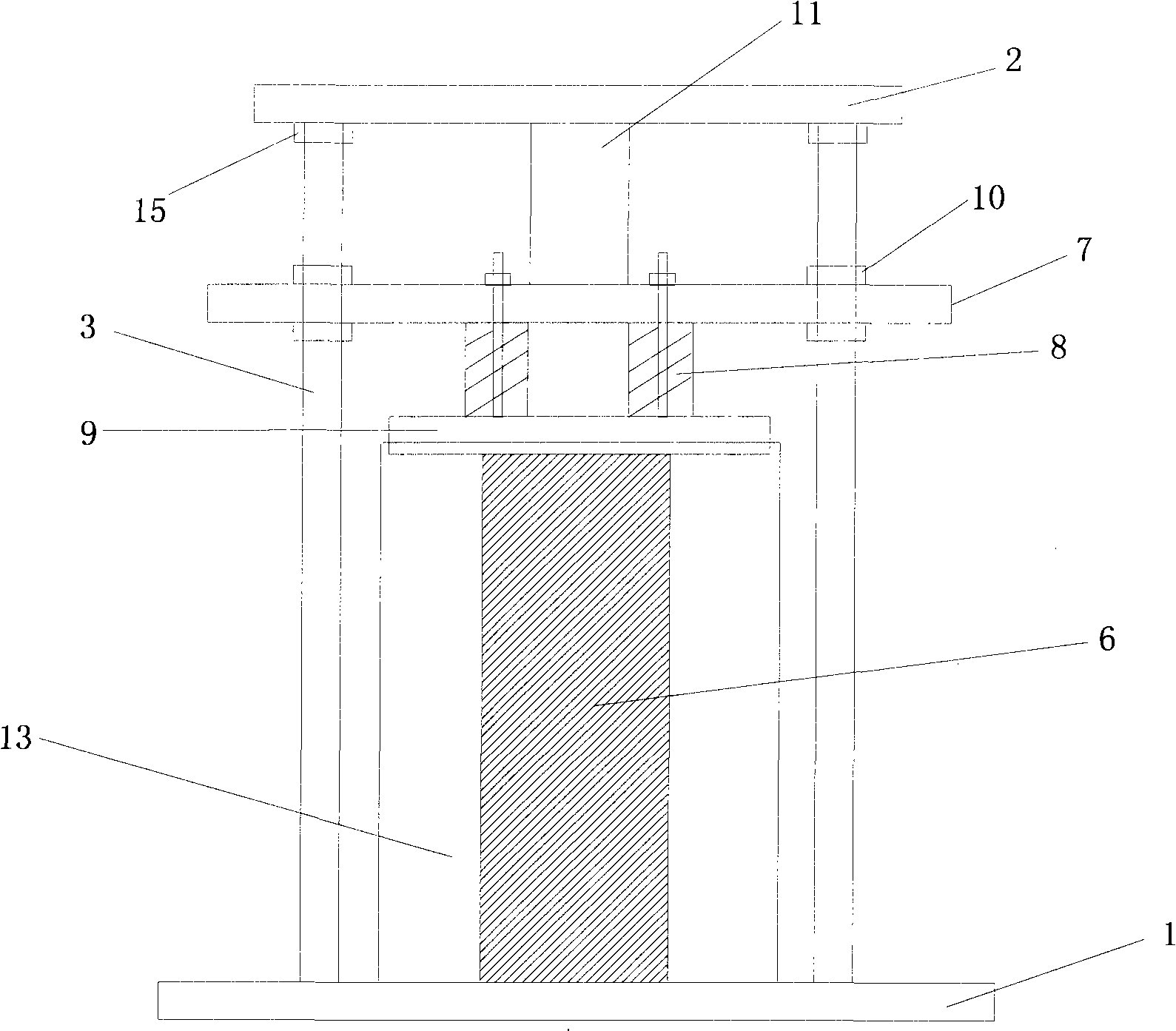

[0020] The device comprises a base plate 1, a pressing plate 7 is arranged directly above the base plate 1, a supporting column 3 is connected between the base plate 1 and the pressing plate 7, one end of the supporting column 3 is fixed on the base plate 1, and the other end is provided with a screw thread and runs through the pressing plate 7; The supporting column 3 is provided with two nuts 10 matched with threads, and the two nuts 10 are located on the upper and lower sides of the pressing plate 7; A test piece 6 is clamped between the bottom plate 1 and the bottom plate 1.

[0021] A jack 11 is provided at the middle part of the upper side of the pressing plate 7 , and the upper side of the jack 11 is in contact with the upper top plate 2 . The upper top plate 2 is connected with the support column 3 by bolts 15 , that is, the upper top plate 2 is directly fixed on the support column 3 by bolts 15 . A water tank 13 is provided between the splint 9 and the bottom plate 1...

Embodiment 3

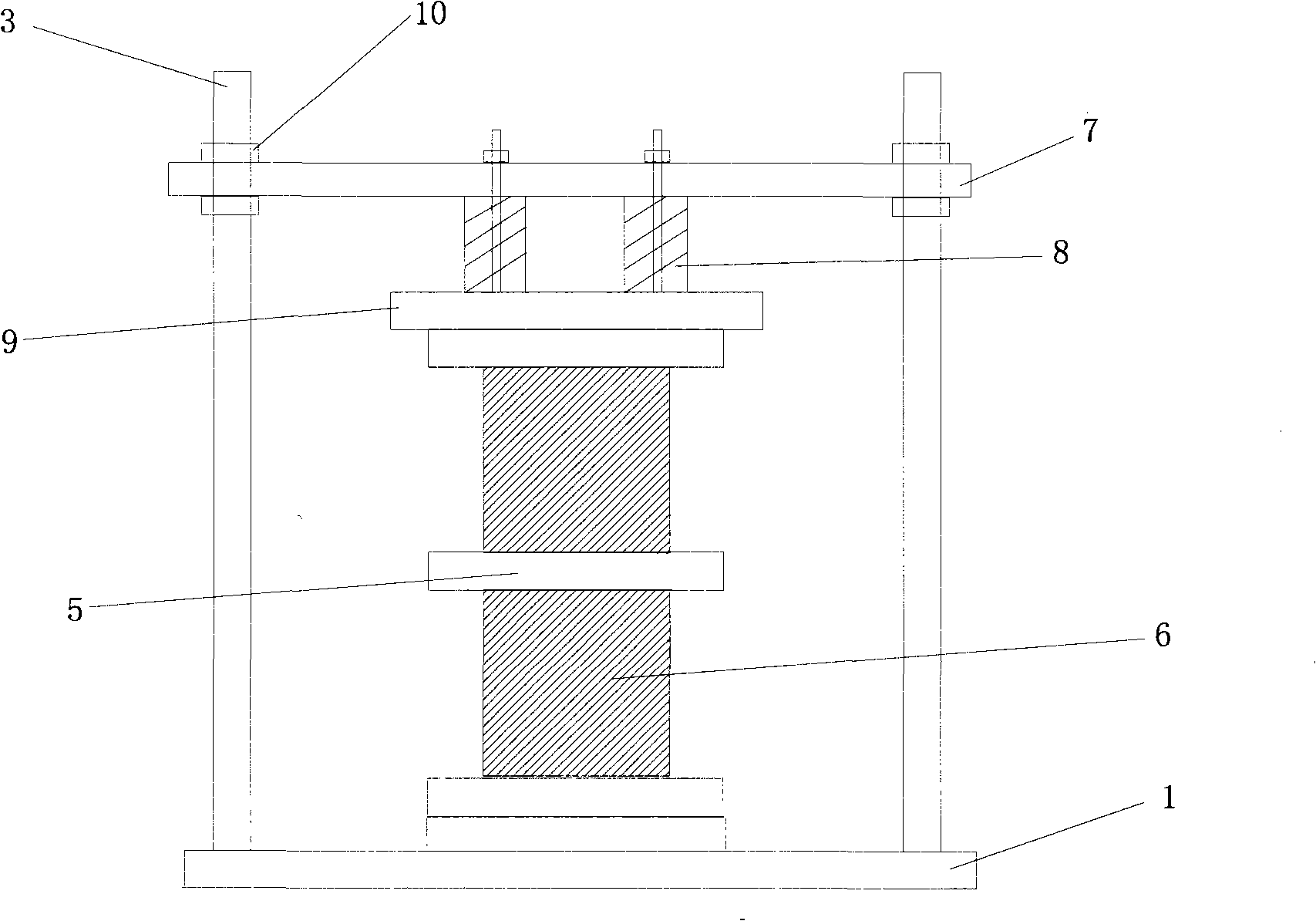

[0024] The device comprises a base plate 1, a pressing plate 7 is arranged directly above the base plate 1, a supporting column 3 is connected between the base plate 1 and the pressing plate 7, one end of the supporting column 3 is fixed on the base plate 1, and the other end is provided with a screw thread and runs through the pressing plate 7; The supporting column 3 is provided with two nuts 10 matched with threads, and the two nuts 10 are located on the upper and lower sides of the pressing plate 7; Two test pieces 6 are clamped between the base plate 1 .

[0025] The upper side of the bottom plate is provided with a positioning spacer 4 , and the positioning spacer 4 is located directly below the splint 9 . Grooves are arranged on the positioning block 4, and the rollers 5 are embedded in the grooves. Rollers 5 are arranged between the upper and lower test pieces 6 and between the test piece 6 and the splint 9 .

[0026] Put the test piece 6 in the test device, loosen t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com