Method and device for testing environmental fracture toughness of petroleum pipe

A technology for oil pipes and fracture toughness, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc. It can solve the problems of large dispersion of experimental results, inability to accurately obtain the value of fracture toughness, accuracy of loading stress, and poor parallelism. , to achieve the effect of a reliable experimental method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

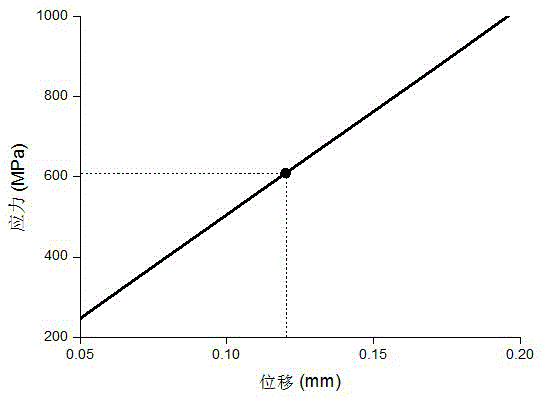

[0038] Use oil pipe A to process the sample according to the requirements, determine the corrosive medium and the loading stress according to the service conditions, and the relationship between loading deflection and stress is as follows: image 3 , the detailed loading data is shown in Table 1.

[0039] After 168 hours of corrosion, it was found that the impact toughness of oil pipe A after the corrosion test was significantly lower than that of the original state, the reduction rate was 14.8%, and the fracture toughness was reduced by 48.8%. 2 S and CO 2 The partial pressures were 1MPa and 1.5MPa respectively, and the toughness and impact resistance decreased to a certain extent after 168 hours of testing under the condition of loading 80% of the nominal yield stress. There is a certain risk in this corrosive environment. The detailed results are shown in Table 2. Figure 4 .

example 2

[0041] Utilize the present invention to test the environmental fracture toughness of oil pipe B, the experimental conditions are temperature 60°C, total pressure 10MPa, H 2 S and CO 2 The partial pressure was 1MPa and 1.5MPa respectively, and the test was carried out under the condition of loading 80% of the nominal yield stress for 14 days. The experimental data and results are shown in Table 3. After the corrosion test, the impact performance and fracture toughness of oil pipe B decreased by 90.5% and 93.5% respectively compared with the original state. , indicating that oil pipe B has poor resistance to stress corrosion cracking in this environment, and cracks initiate and grow rapidly, which greatly reduces the toughness and impact resistance of oil pipe B, and the possibility of environmental fracture is very high, so it is not suitable for this environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com