A double structural plane direct shear test method for studying the mechanism of sliding rockburst

A test method and structural surface technology, applied in the field of rock mechanics, can solve problems such as failure to reflect the conditions of rockburst occurrence, and achieve the effect of a reliable test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

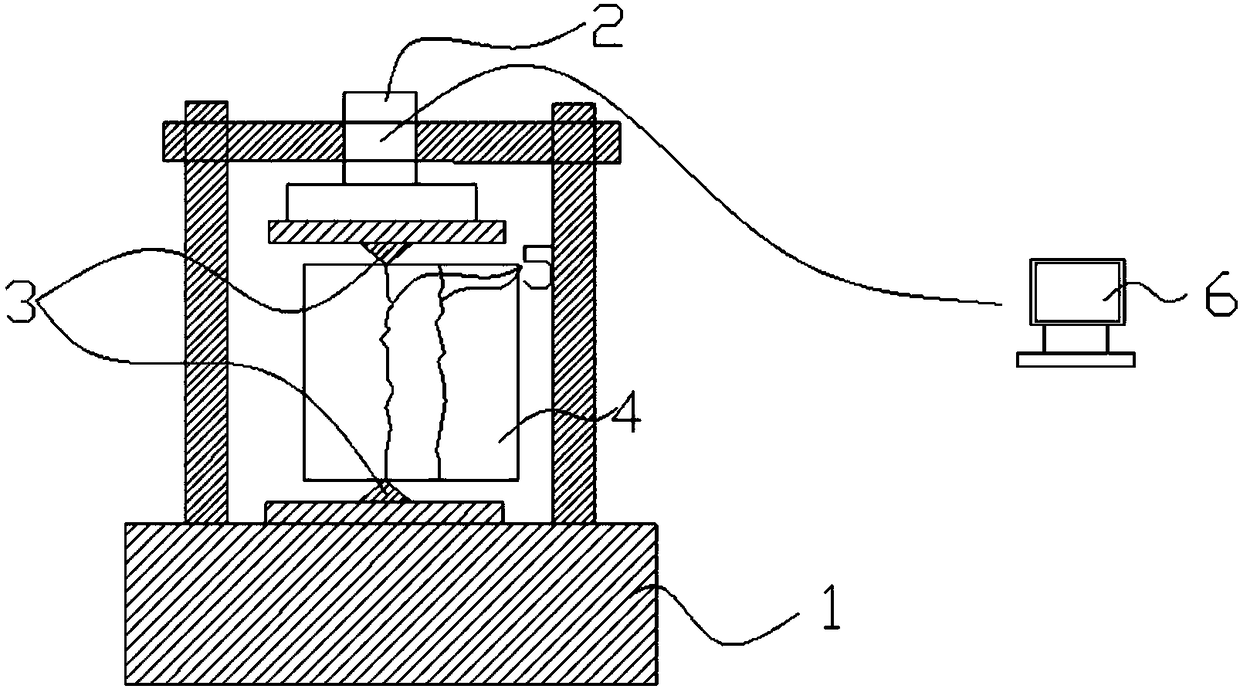

[0034] The double structural plane direct shear test method for studying the mechanism of sliding rockburst is adopted for granite, including the following steps:

[0035] Step 1: making the granite into a rock sample with a square section, the size of which is 100mm×100mm×140mm (length×width×height);

[0036] Step 2: Sequentially generate double parallel structural planes on the granite sample under Brazilian splitting conditions, with a distance of 40 mm between the structural planes. At this time, the granite sample is divided into three pieces with thicknesses of 50 mm, 40 mm, and 50 mm, respectively, as figure 1 shown;

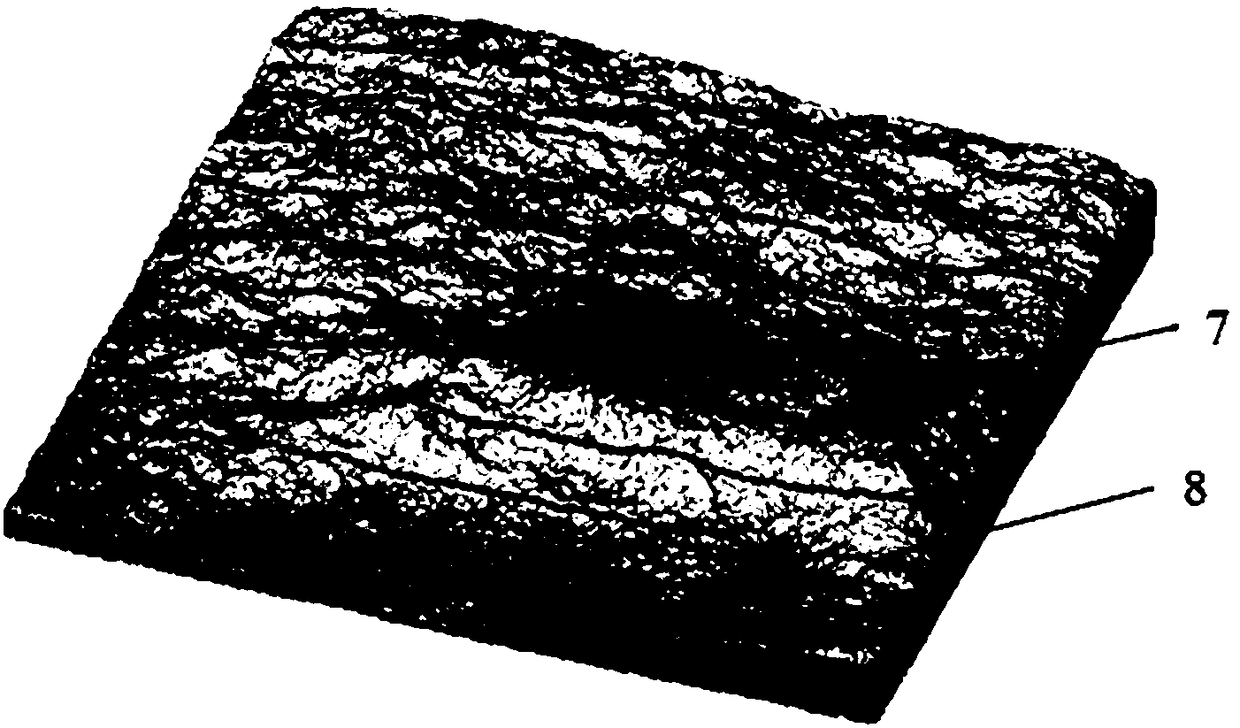

[0037] Step 3: Carry out 3D scanning on the double-parallel structural planes respectively to obtain a three-dimensional digital model of the double-parallel structural planes, figure 2 A 3D digital model of the upper structural face of the double parallel structural face is provided, in figure 2 Cut 10 section lines at equal intervals along the shear...

Embodiment 2

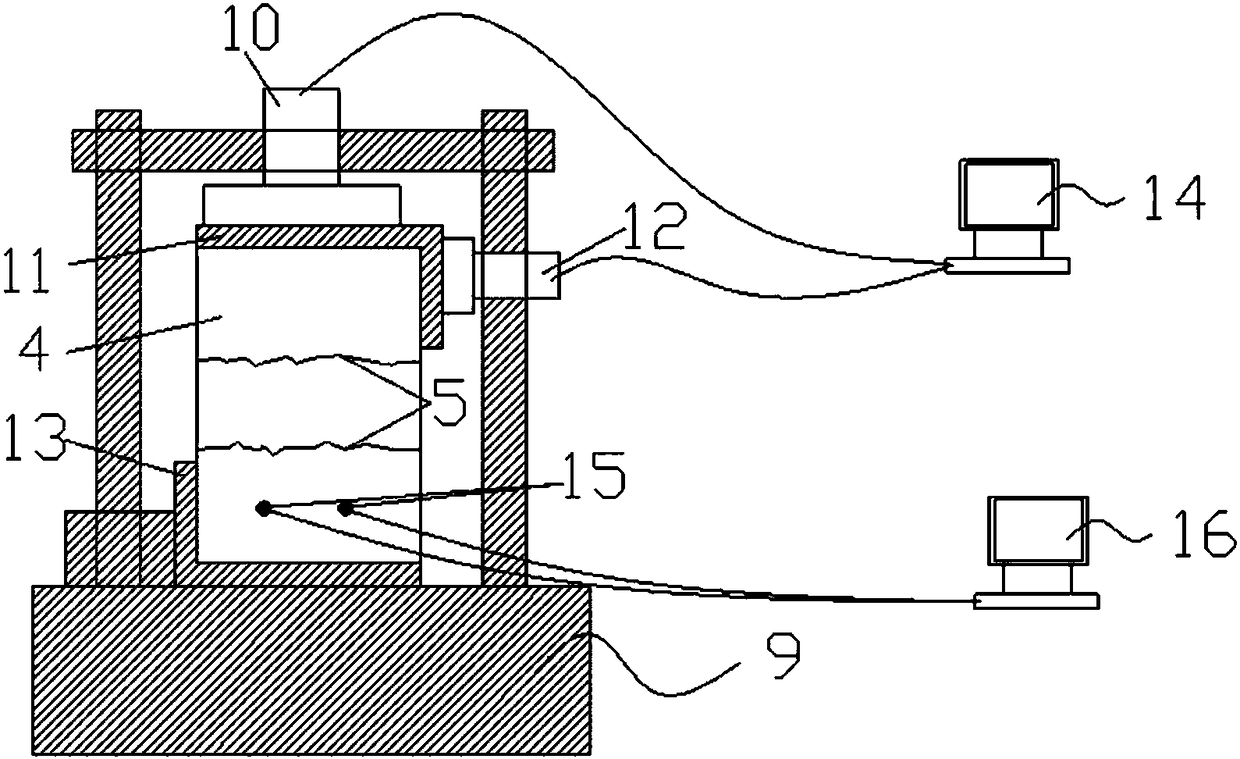

[0051] The double structural plane direct shear test method for studying the mechanism of sliding rockburst is adopted for granite, including the following steps:

[0052] Step 1: Make the granite into a rock sample with a square section, the size is 100mm×100mm×140mm (length*width*height);

[0053] Step 2: Sequentially generate double parallel structural planes on the granite sample under Brazilian splitting conditions, with a distance of 40 mm between the structural planes. At this time, the granite sample is divided into three pieces, with thicknesses of 50 mm, 40 mm, and 50 mm;

[0054] Step 3: Carry out 3D scanning on the double-parallel structural planes respectively to obtain a three-dimensional digital model of the double-parallel structural planes, Figure 10 A 3D digital model of the upper structural face of the double parallel structural face is provided, in Figure 10 Cut 10 section lines at equal intervals along the shearing direction, the interval between sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com