Pressure test method for power station valve

A technology of power station valve and test method, which is applied in the direction of measuring the acceleration and deceleration rate of fluid, using liquid/vacuum degree for liquid tightness measurement, etc. problems such as leakage, to achieve good operability and accuracy, accurate and reliable experimental methods, and a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A sealing test method for a valve in a power station. The valve to be tested is connected to the test pipeline, and the connection is set according to the requirements of the sealing test. First, the valve is heated to a set temperature, and the set temperature is 37-700 ° C, and then filled with helium. , do a sealing test with the gauge pressure not lower than 1.1 times the nominal pressure, and continue for the set time under the heat preservation and pressure holding state. If the pressure value drops beyond the set standard, it will be judged as unqualified.

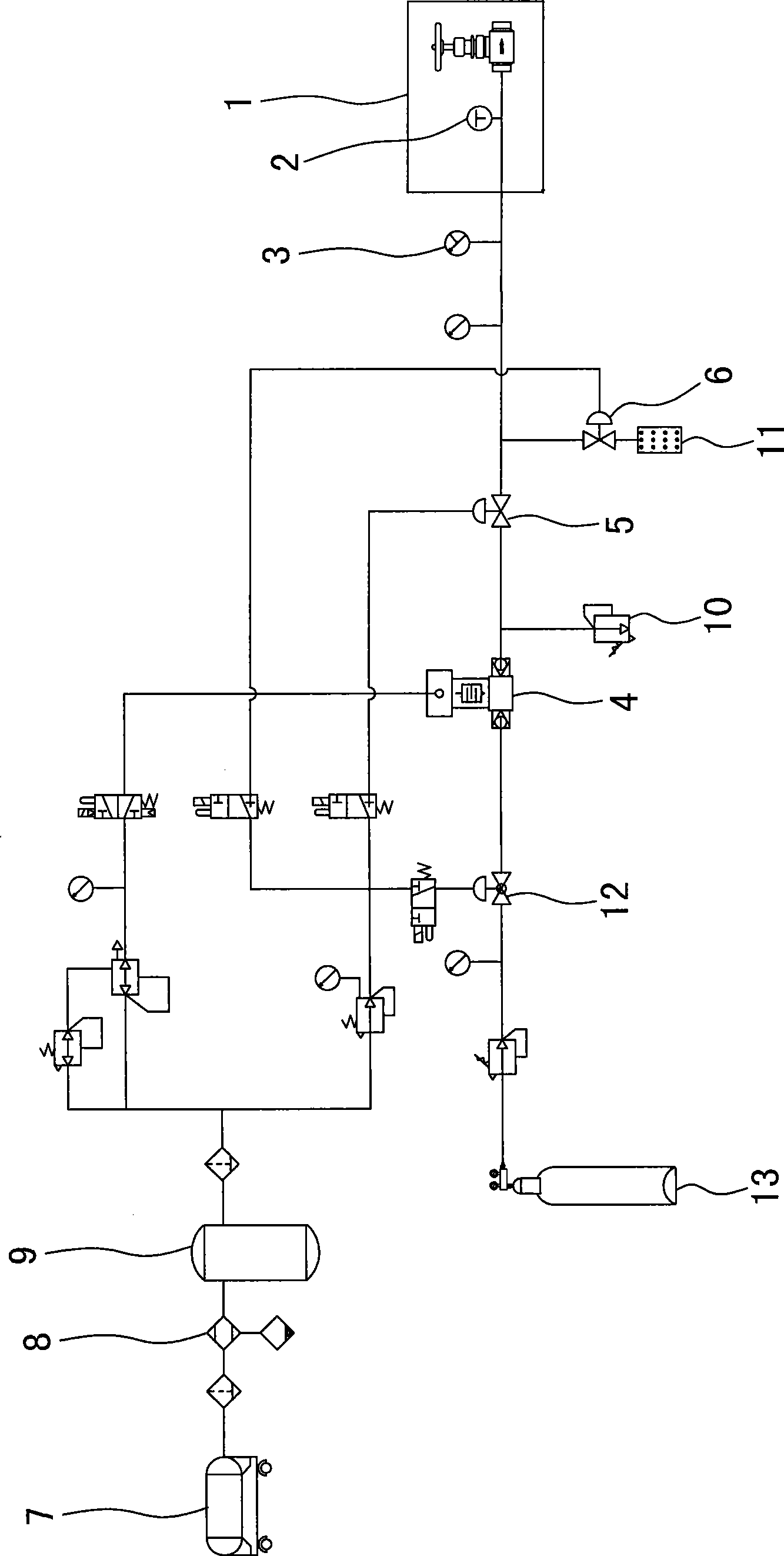

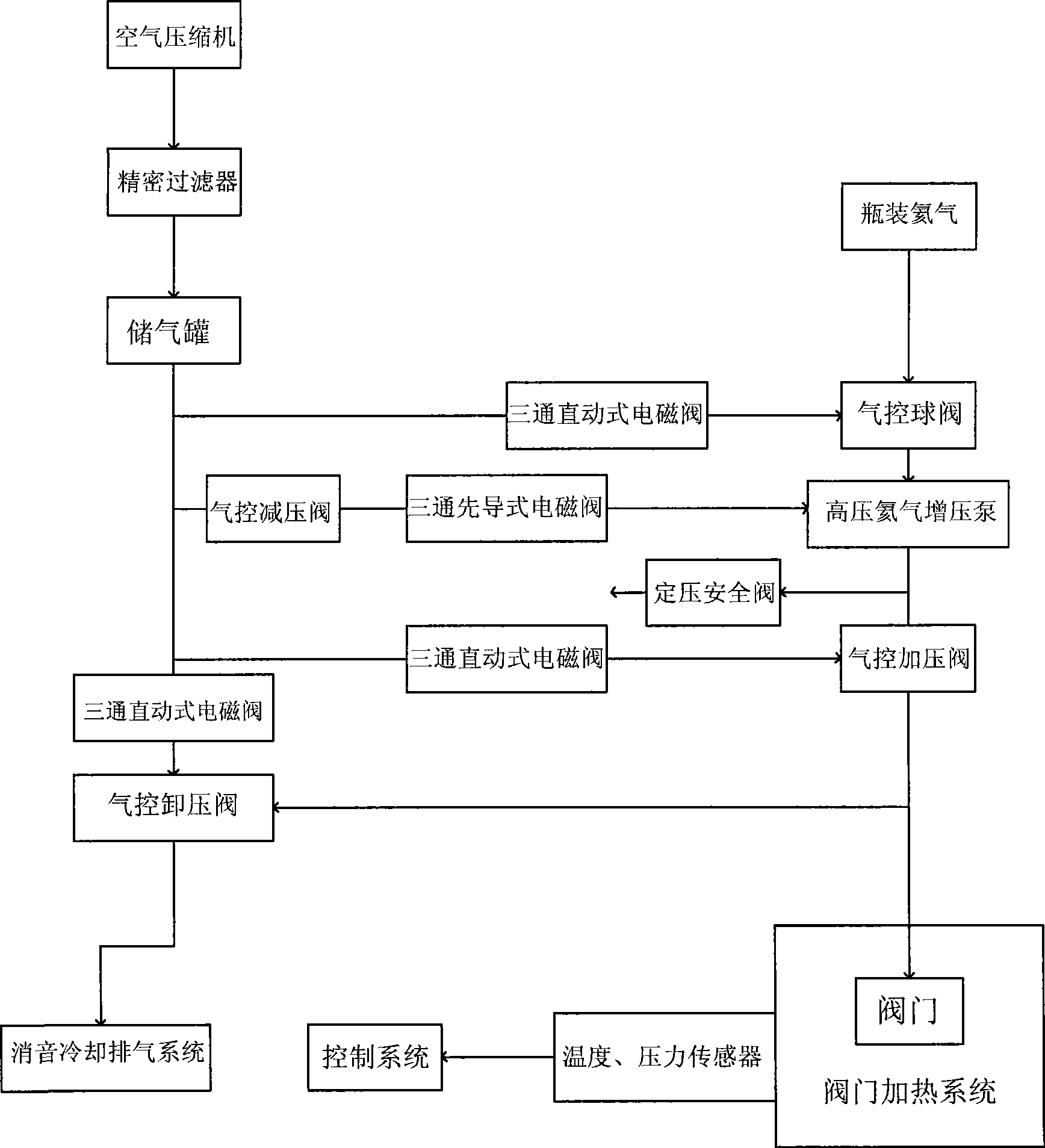

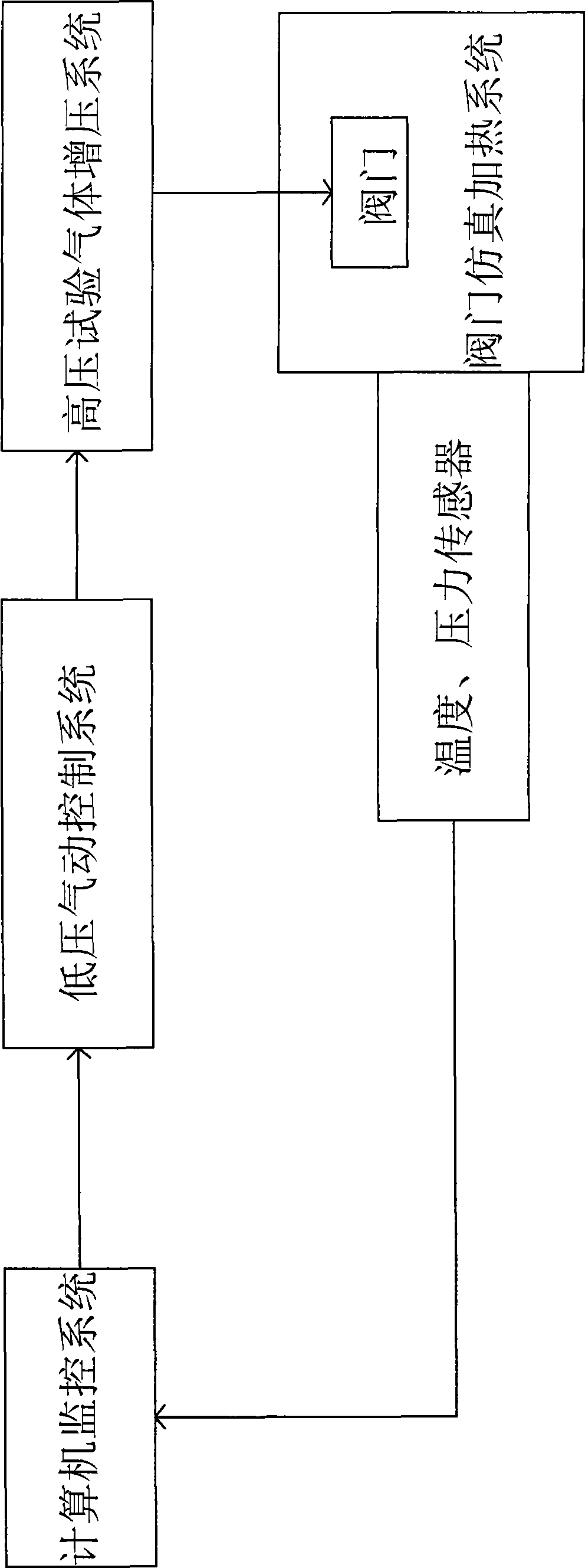

[0029] Device of the present invention see Figure 1~3 As shown, a pressure test device for valves in a power station includes a valve simulation heating system, a high-pressure test gas pressurization system, a low-pressure pneumatic control system and a computer monitoring system;

[0030] The valve simulation heating system includes a box-type resistance furnace 1, a temperature sensor 2, and a pressure se...

Embodiment 2

[0044] A shell test method for a valve in a power station. The valve to be tested is connected to the test pipeline, and the connection is set according to the shell test requirements. First, the valve is heated to a set temperature, and the set temperature is 648.0°C, and then filled with helium. , for a shell test where the gauge pressure is not lower than 1.5 times the nominal pressure, and it lasts for 15s under the condition of heat preservation and pressure preservation. If the pressure value drops by more than 0.1MPa, it is judged as unqualified. The specification and model of the valve used is 316NB-GM6, as shown in the following table:

[0045] Set pressure / MPa Set temperature / ℃ Leakage Judgment / MPa Holding time / S Stabilization time / S) 20.0 648.0 0.1 15.0 0.0 Initial pressure / MPa Initial temperature / °C Leakage pressure / MPa Drop temperature / ℃ Comprehensive leakage / MPa 21.0 650.0 0.0 -1.5 0.0

[0046] It can be seen tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com