A valve thermal test device

A thermal test and valve technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., to achieve stable temperature and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

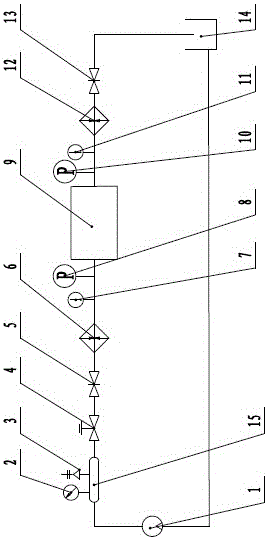

[0014] like figure 1 As shown, a valve thermal test device includes a tested valve 9, a water pump 1, a surge tank 15, a pressure regulating valve 4, a pressure sensor A8, a pressure sensor B10, a shut-off valve A5, a shut-off valve B13 and a water tank 14, and the water pump 1 is connected to the pressure-stabilizing tank 15, and the pressure-regulating valve 4, shut-off valve A5, pressure sensor A8 and the tested valve 9 are sequentially connected behind the pressure-stabilized tank 15, and the pressure sensor B10, shut-off valve B13, The water tank 14, the water tank 14 is connected with the water pump 1, the above-mentioned components are all connected by pipelines, the pressure gauge 2 and the safety valve 3 are installed on the surge tank 15, the thermometer A7 and the pressure sensor are installed between the pressure sensor A8 and the cut-off valve A5 Thermometer B11 is installed between B10 and shut-off valve B13, electric heater A6 is installed on the pipeline betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com