High-temperature high-pressure constant load stress corrosion experiment method and device

A high temperature and high pressure, stress corrosion technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, and application of stable tension/pressure to test the strength of materials, etc. On-site metal material selection and applicability evaluation provide reliable guarantees and other issues to achieve the effect of reliable experimental methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

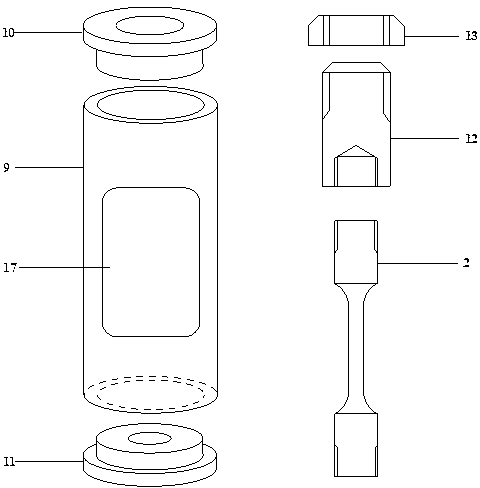

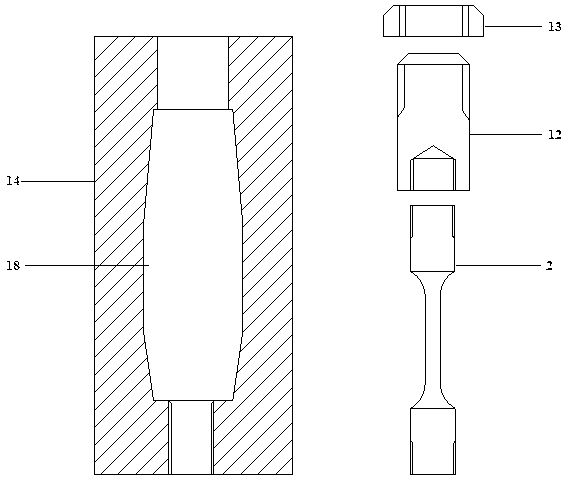

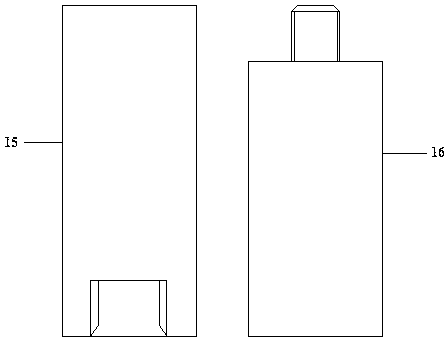

[0025] refer to figure 1 Shown, a kind of high temperature high pressure constant load stress corrosion test device among the present invention mainly comprises high temperature autoclave (1), sample (2), circular fixture (3), insulating spacer (4), vapor phase corrosion medium ( 5), gas-liquid interface (6), liquid-phase corrosive medium (7), plate-type fixture (8), round fixture body (9), upper clamping end (10), lower clamping end (11), connector (12), loading nut (13), plate fixture main body (14), tensile test upper fixture (15), tensile test lower fixture (16), round fixture window (17), plate fixture window (18) ); the high-temperature autoclave (1) volume is large enough to be able to put into three groups of circular clamps (3) or plate-shaped clamps (8) to carry out parallel experiment simultaneously; Described sample (2) is a standard tensile sample or small-sized tensile sample; the circular clamp (3) is composed of a circular clamp main body (9), a sample (2), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com