A kind of high temperature and high pressure dynamic galvanic corrosion test method and device

A technology of galvanic corrosion, high temperature and high pressure, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of unsatisfactory material selection, inability to accurately load torque, inability to select metal materials on site and applicability evaluation to provide reliable Guarantee and other issues to achieve the effect of a reliable experimental method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

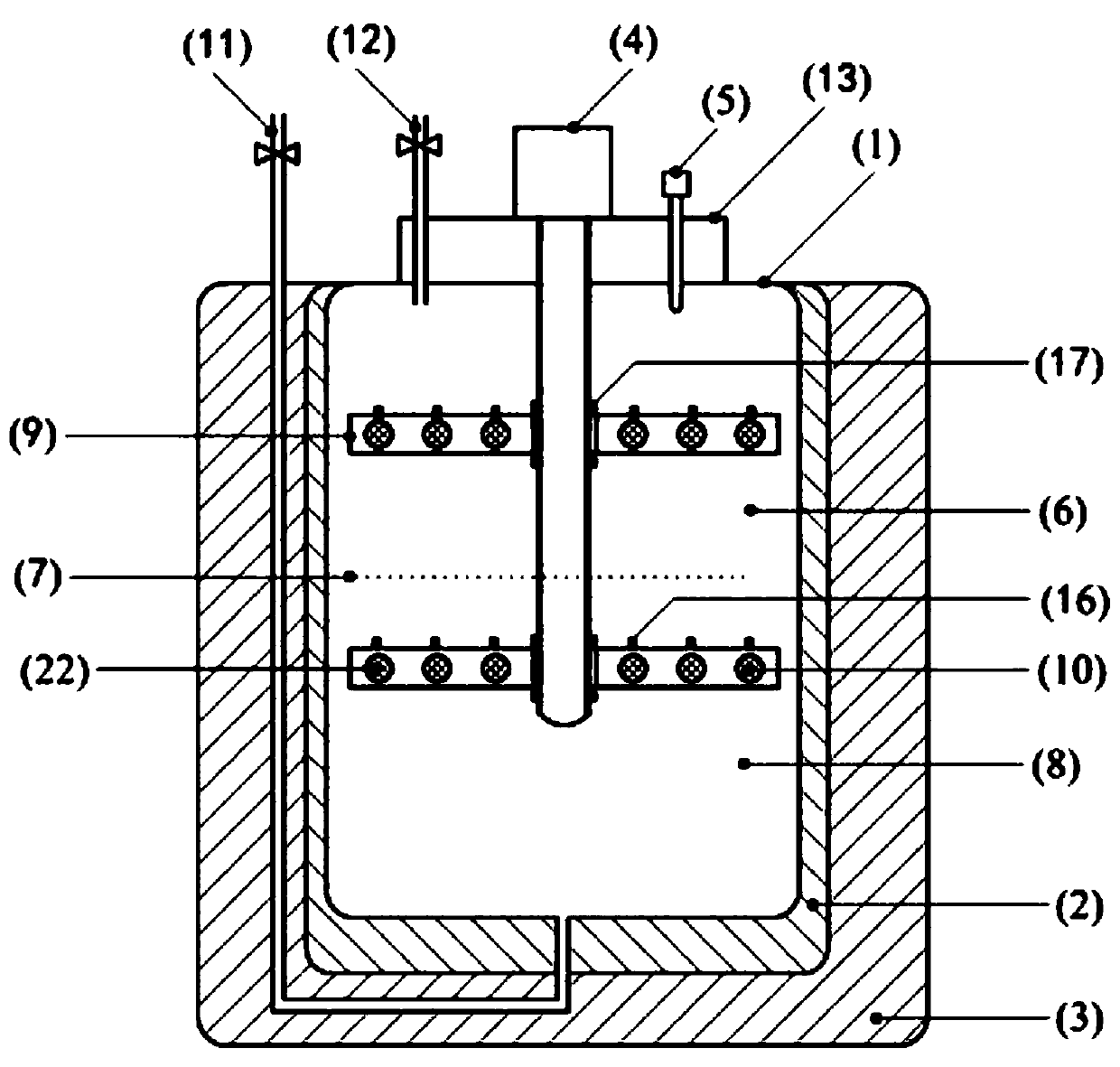

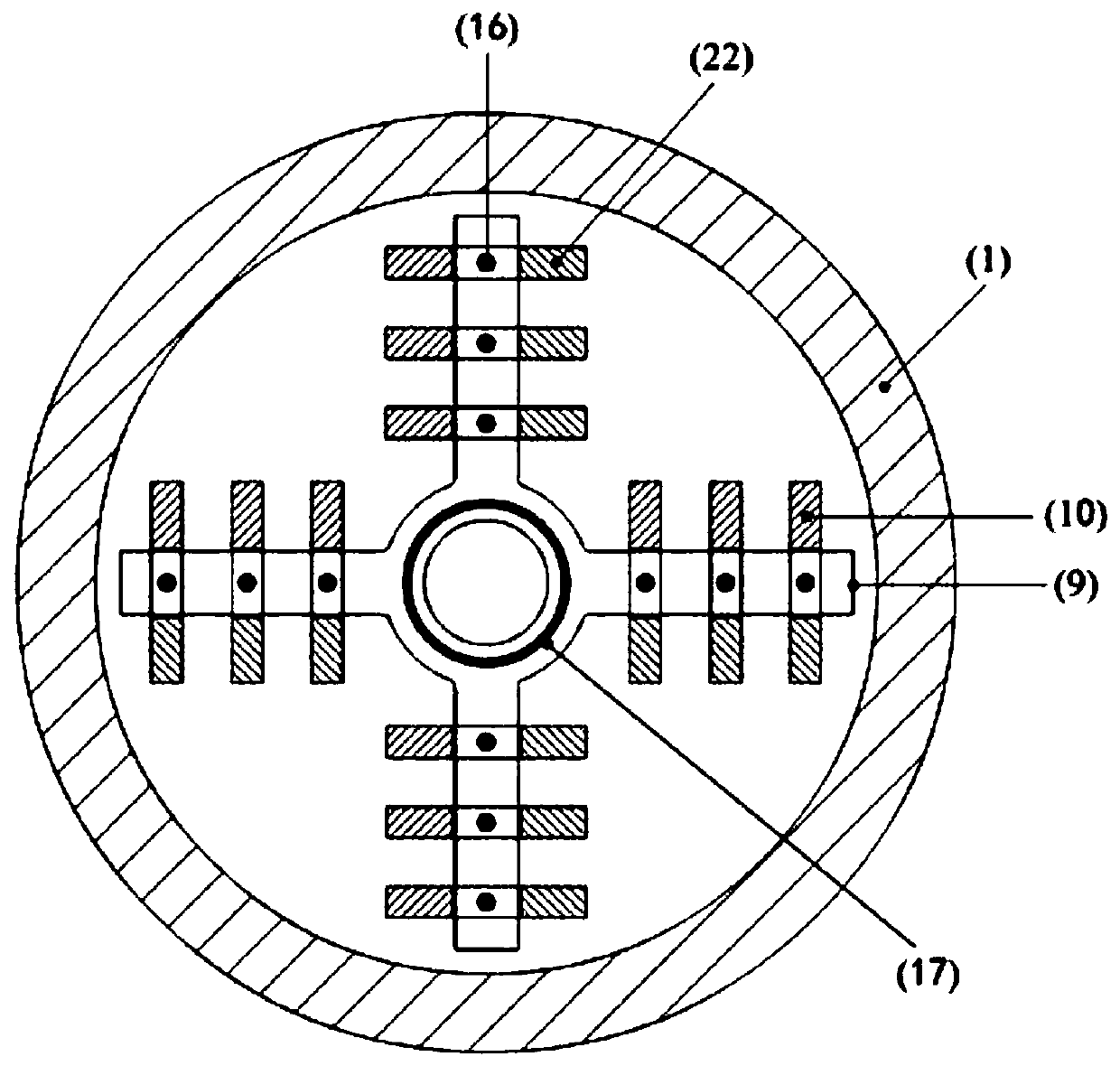

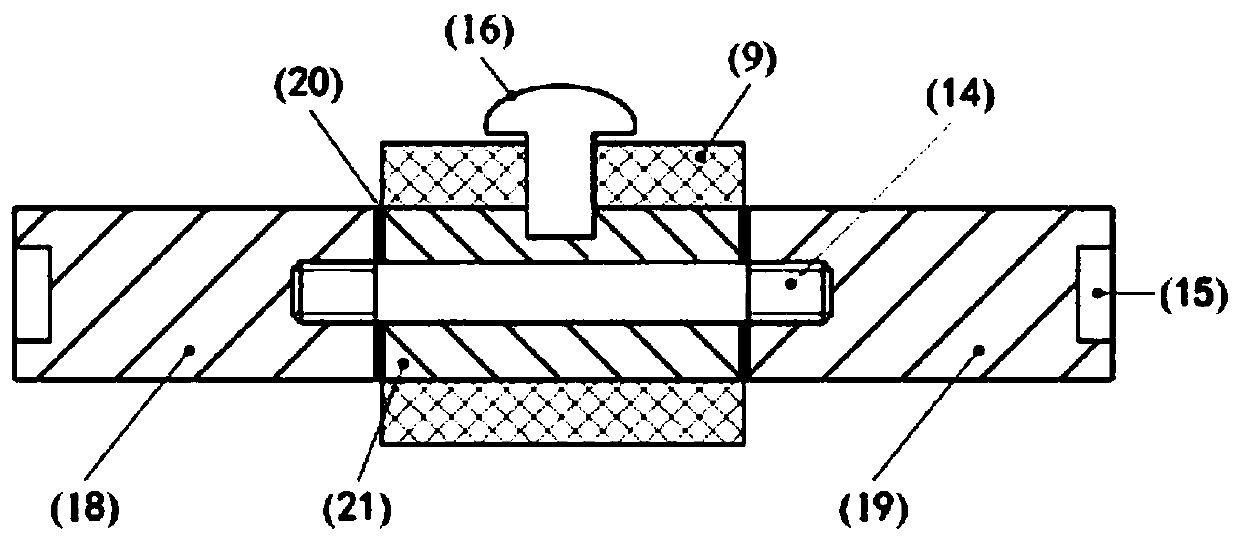

[0022] refer to figure 1 As shown, a high temperature and high pressure dynamic galvanic corrosion experimental device in the present invention mainly includes a high temperature autoclave 1, a heating system 2, a heat preservation system 3, a magnetic rotation system 4, a temperature and pressure sensor 5, a gas phase corrosion medium 6, and a gas-liquid interface 7. Liquid phase corrosion medium 8. Sample clamping device 9. Galvanic couple sample I10, air inlet 11, air outlet 12, kettle cover 13, current connecting rod 14, inner hexagon hole 15, positioning pin 16, fixer 17. Metal sample A18, metal sample B19, insulating gasket 20, insulating connecting rod 21, galvanic couple sample II22, cavity 23; the high temperature and autoclave 1 is provided with a heating system 2, a heat preservation system 3, a temperature and pressure Sensor 5, gas phase corrosion medium 6, liquid phase corrosion medium 8, sample holding device 9, galvanic couple sample I10, galvanic couple sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com