Simulation experiment method for tunnel drivage blasting

A technology for simulating experiments and tunnels, applied in the field of experiments, can solve problems such as poor cutting effect and low utilization rate of blastholes, and achieve the effect of reliable experimental methods and reliable experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

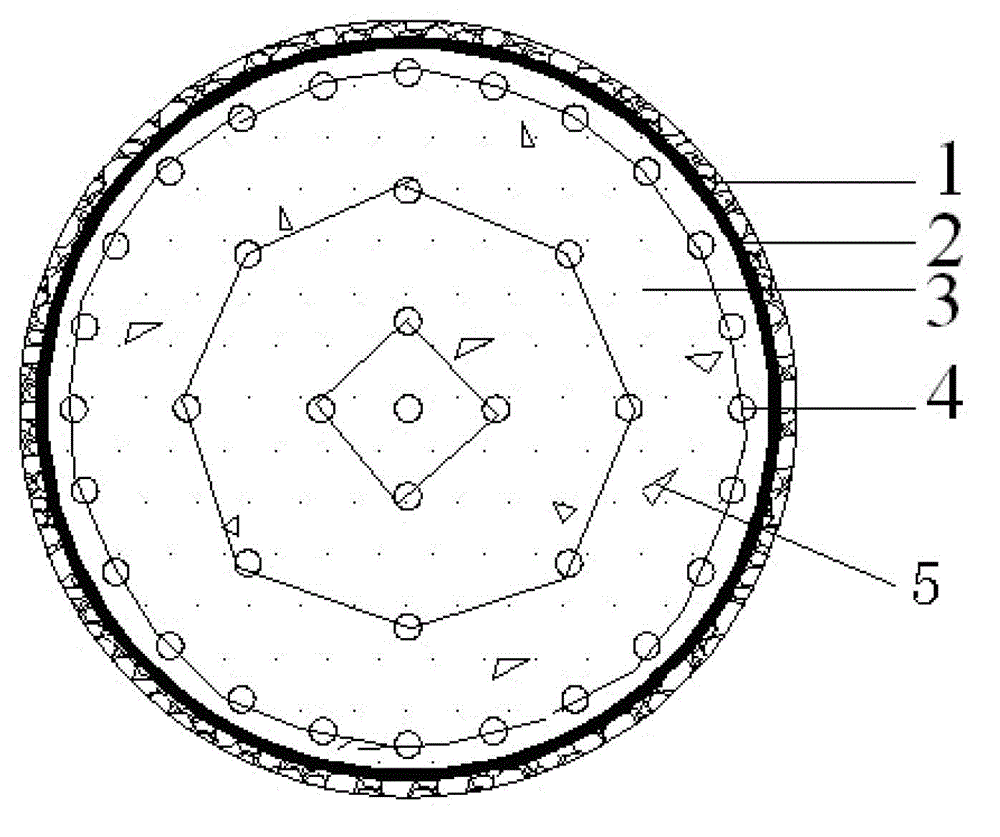

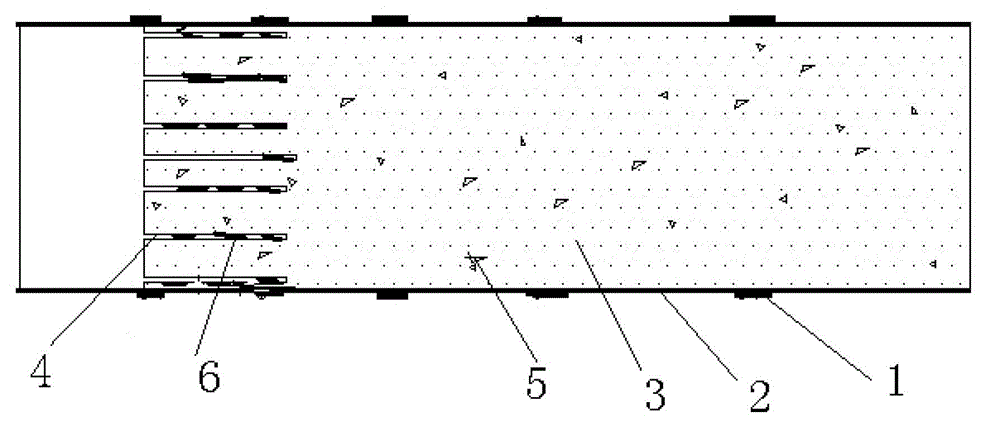

[0022] The present invention is further described with reference to accompanying drawing, and accompanying drawing is an example with circular roadway section. The section of a roadway in a project is circular, with a diameter of 5.0m. The rock is sandy shale with medium joints and a single structure. Each blasting footage is 2.0-2.5m. The problem of poor effect and low blasthole utilization rate is now simulated by the experimental method of the present invention.

[0023] An experimental method for simulating tunneling blasting is as follows:

[0024] The first step is to make the blasting experimental device

[0025] Take a section of circular steel cylinder 2 similar to the section of the actual roadway as the constraint for simulating the rock mass around the roadway. The thickness is 3mm, the depth of the simulated blasthole is (2.0-2.5) / 5=0.4-0.5m, take 0.5m, the length of the steel cylinder 2 is 3.0 times the depth of the simulated blasthole 4, so the length of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com