Under-deposit corrosion experiment bracket and method for experimenting by using same

A technology of under-deposit corrosion and experimental methods, which is applied in the field of corrosion experiments, can solve problems such as poor reliability, and achieve the effects of reasonable steps, simple device structure, and reliable experimental methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

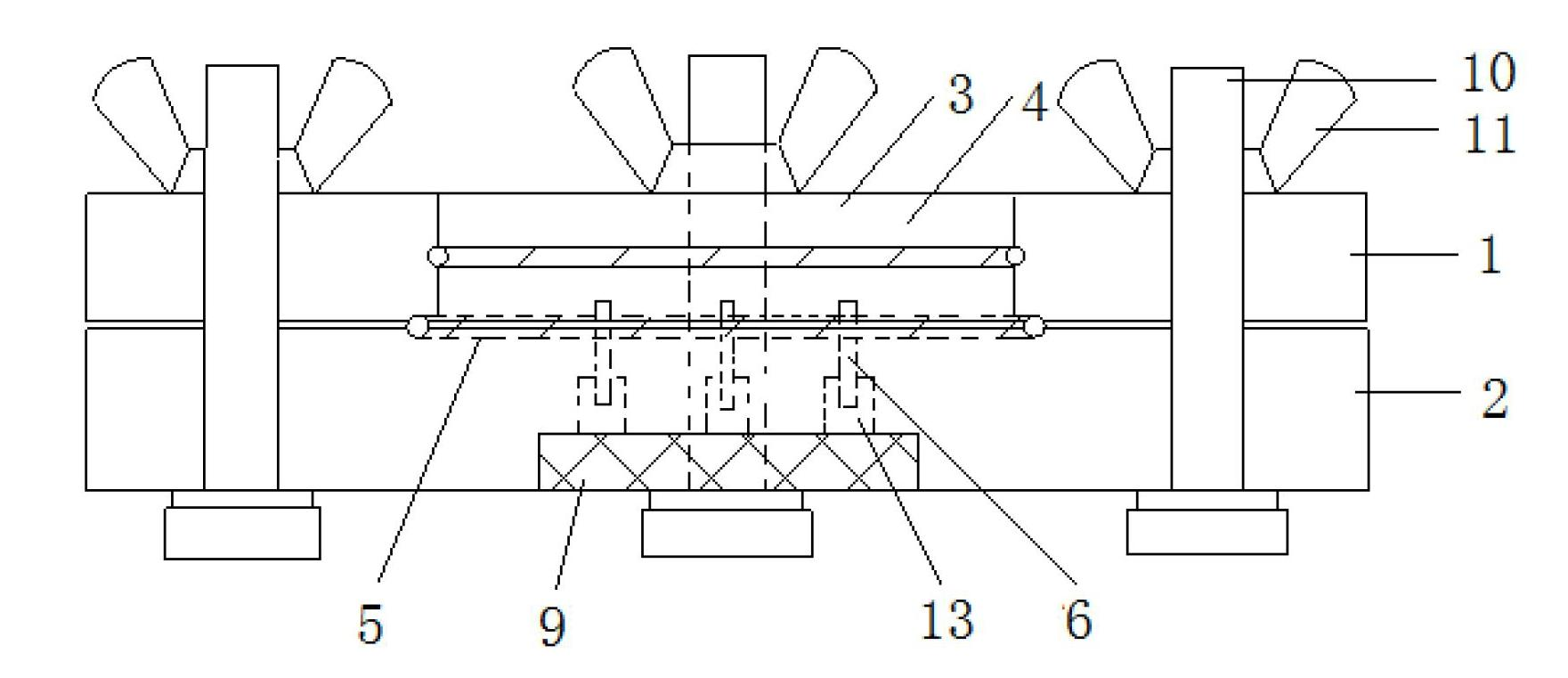

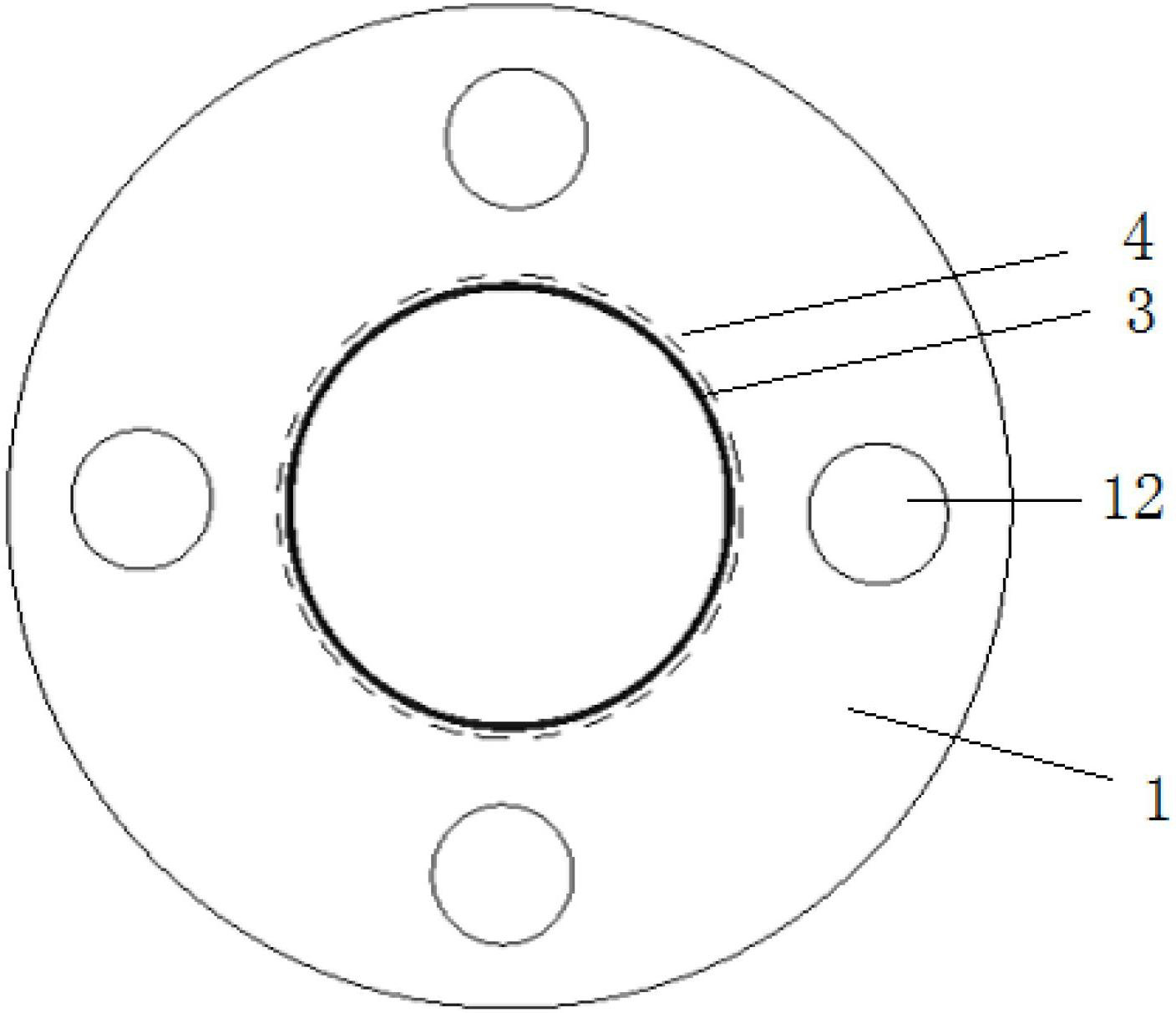

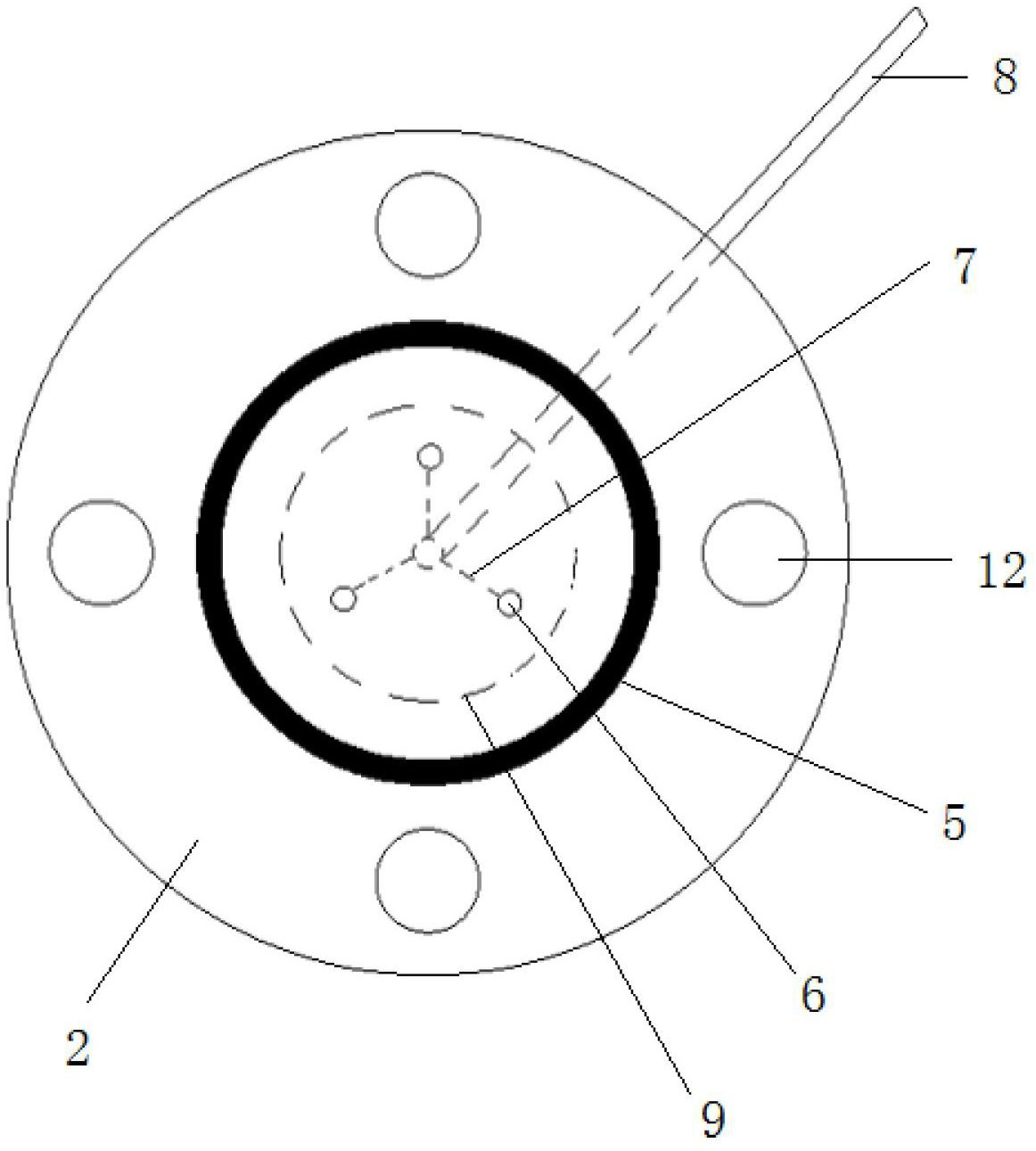

[0024] A kind of support for under-deposit corrosion experiments, comprising a support panel 1 and a support base 2; the outer edges of the support panel 1 and the support base 2 are provided with corresponding fixing holes 12, and the support panel 1 and the support base 2 pass through The fixing parts arranged in the fixing holes 12 are connected and fixed; the bracket panel 1 is provided with a working electrode hole 3 having the same diameter as the working electrode, and a panel groove is arranged around the working electrode hole 3, and the panel concave An embedded panel O-ring 4 for sealing the working electrode is provided in the groove; a base groove is provided on the support base 2, and an inner seal for sealing the support panel 1 and the support base 2 is provided in the base groove. Embedding base O-ring 5; the bracket base 2 is provided with three electrical contacts 6 at positions within the inner diameter circumference of the base O-ring 5, and the lower end o...

Embodiment 2

[0027] A support for under-deposit corrosion experiments is the same as that in Example 1, except that the support panel 1 and the support base 2 are circular, and the number of fixing holes 12 corresponding to the positions provided at the outer edges is four.

[0028] The experimental method of the under-deposit corrosion experiment bracket is the same as in Example 1, except that before the experiment, when the bracket is assembled, the screw 10 is passed through the fixing holes 12 of the bracket base 2 and more than two bracket panels 1, Then tighten the nut 11, and finally add a scale layer to the thickness of the scale layer required by the experiment in the working electrode hole 3 on the working electrode.

Embodiment 3

[0030] A support for under-deposit corrosion experiments is the same as that in Example 1, except that the support panel 1 and the support base 2 are square, and the number of fixing holes 12 corresponding to the positions provided at the outer edges is four.

[0031] In this way, during the experiment, a kind of under-deposit corrosion experiment bracket and its experimental method of the present invention can realize electrochemical corrosion test, corrosion weight loss measurement and surface morphology observation on the same corrosion test piece, which is suitable for electrochemical corrosion and under-deposit corrosion. Corrosion simulation studies, such as CO of oil and gas system equipment 2 and H 2 S corrosion, corrosion of metals at deposits of sand, elemental sulfur and scale, and performance evaluation of corrosion inhibitors, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com