Characterization method of hard brittle high-precision component sub-surface damage degree

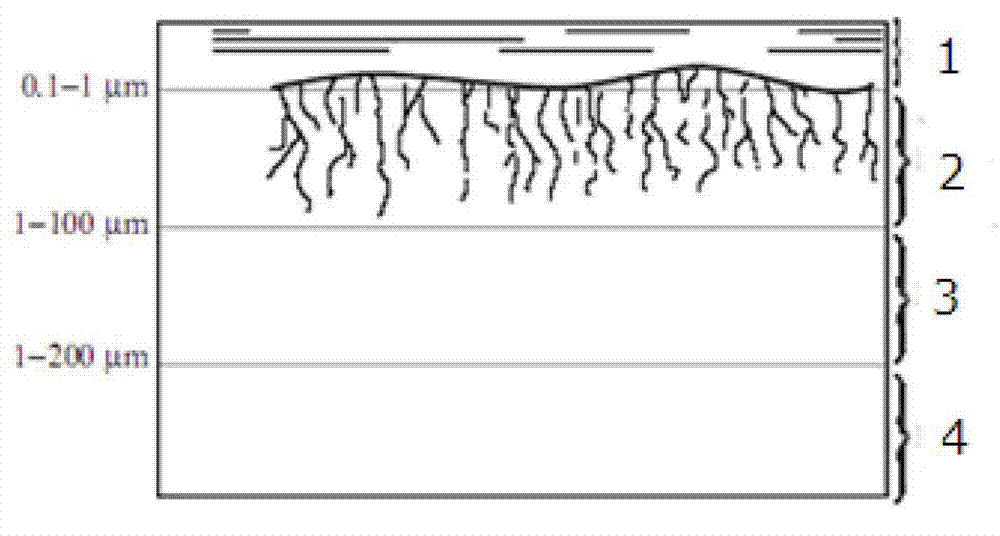

A technology of subsurface damage and hard brittleness, which is applied in the field of characterization of subsurface damage after grinding, polishing and corrosion of hard and brittle high-precision components. The exact depth of subsurface damage layer and the limited prediction accuracy of subsurface damage microcrack depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

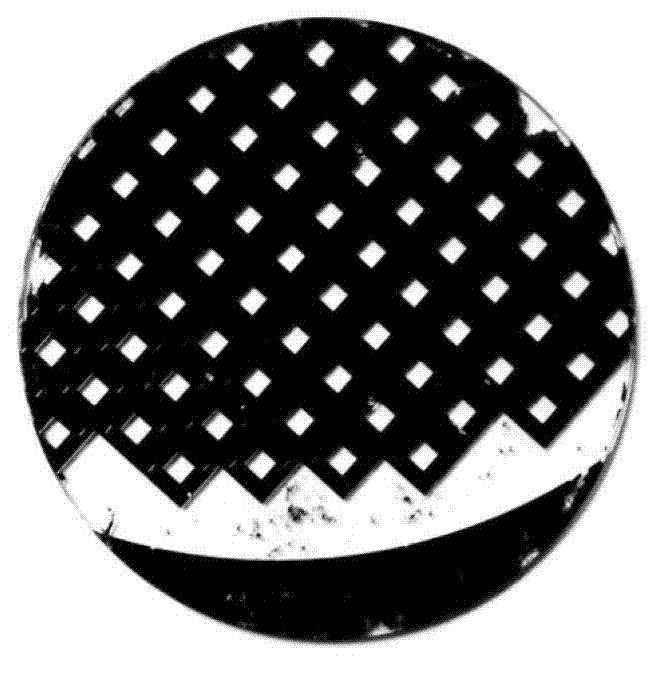

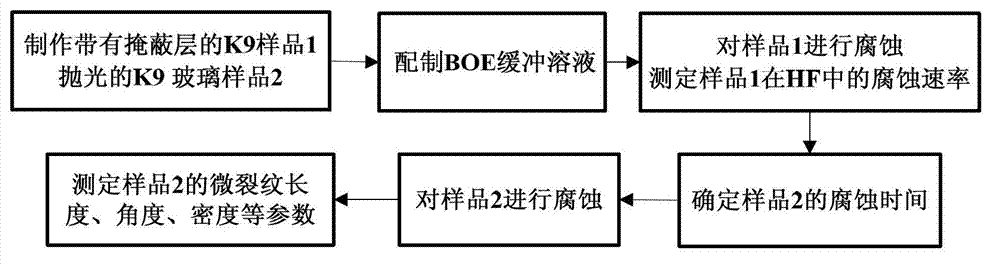

[0025] refer to figure 2 , image 3 First, sputter 100nm thick Cr on a Φ50×2mm K9 glass substrate using a magnetron sputtering machine, use photoresist AZ to uniformly coat the sputtered Cr layer, and use a mask with 2×2mm square holes The film plate is photolithographically etched on the surface of the K9 glass substrate after uniform glue, and then the sample is developed in a 5‰ NaOH solution for 5 minutes, and the film is hardened in a dryer at 95°C for 3 hours, and the square hole is etched with cerium ammonium nitrate Cr in about 50 seconds, made into a 2 × 2mm square patterned substrate with a Cr masking layer ( figure 2 ). Use a step profiler to detect the depth of the masking layer square pattern and record the data. Put the substrate of the Cr mask into the BOE solution (buffer solution of hydrofluoric acid), etch it in a water bath with a constant temperature of 25°C, and then use a step profiler to detect the depth of the square pattern on the unmasked part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com