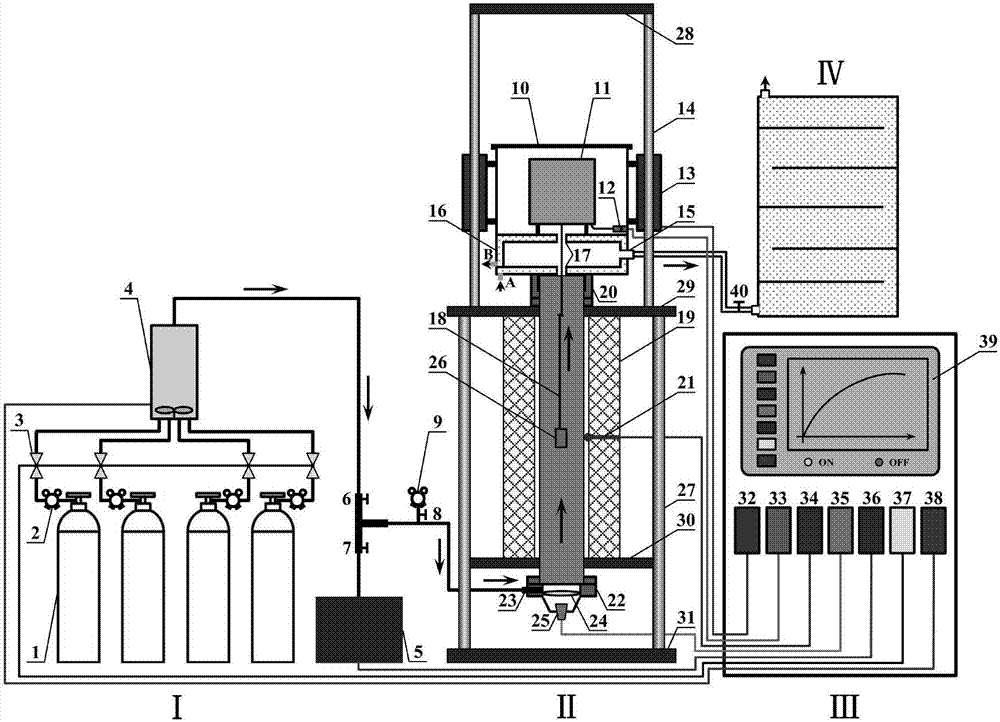

Testing apparatus capable of simulating high-temperature corrosion

A high-temperature corrosion and test device technology, which is applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc. Problems such as the low degree of intelligent automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

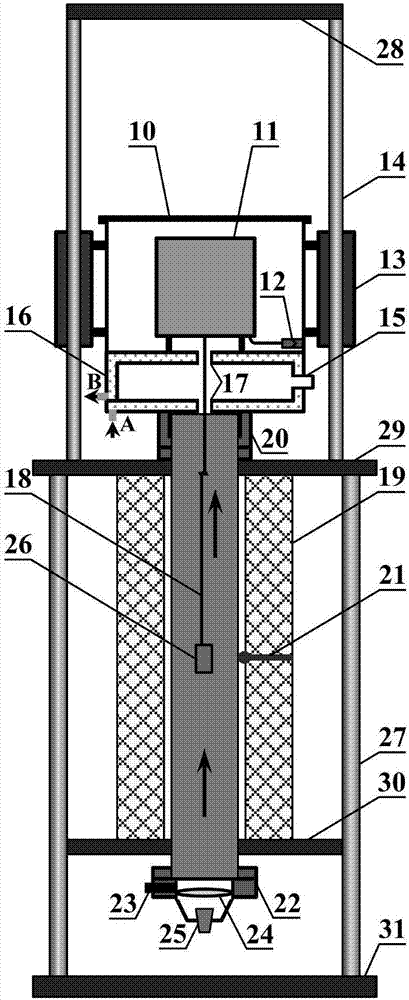

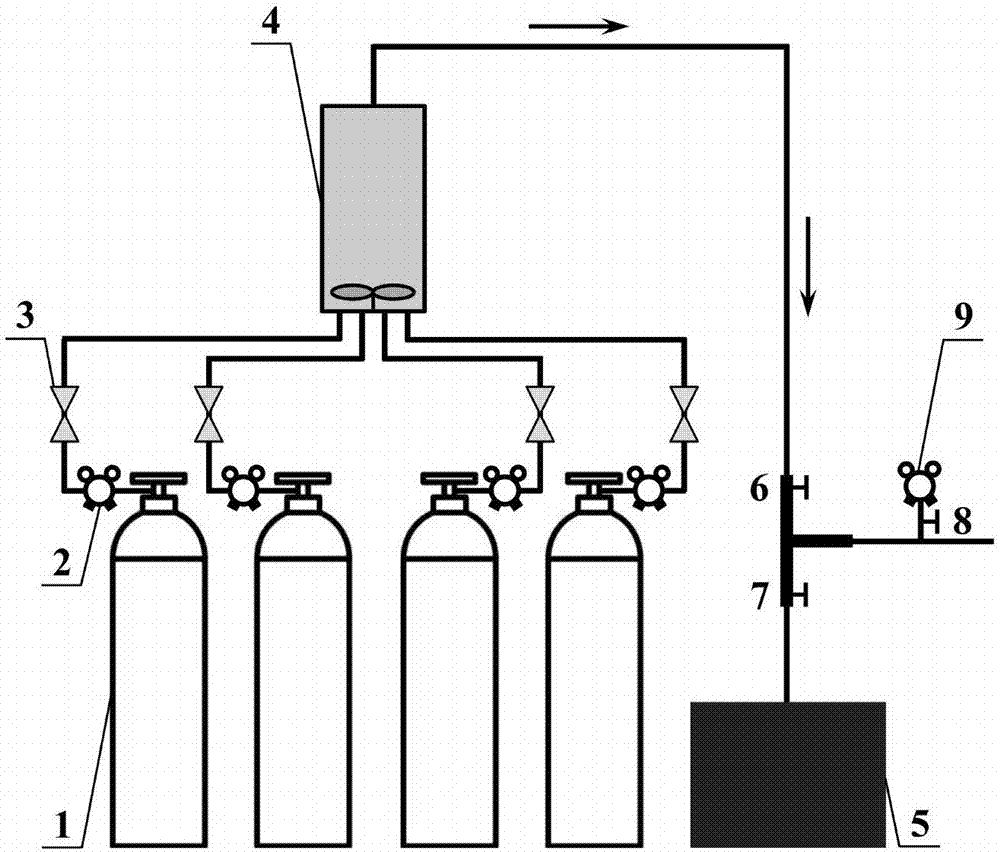

[0073] This example mainly simulates the high-temperature corrosion experiment in which various sedimentary salts coexist in the waste incineration environment, and specifically includes the following steps:

[0074] Step 1: Turn on the cooling water switch and the power supply of the electric control cabinet, set the temperature raising program in the special control software, and raise the temperature in the heating furnace 19 to 800°C.

[0075] Step 2: Input the ascent speed and ascent distance as 1m / min and 0.5m respectively in the special control software, and lift the weighing device box 10 . Evenly coat the surface of super austenitic stainless steel 254SMO sample 26 with salt (40% NaCl+40% KCl+10% Na 2 SO 4+10%K 2 SO 4 ) into the corundum crucible and hung on the bottom end of the hanging wire 18 connected to the weighing device 11. In the dedicated control software, input the descending speed and the descending distance as 1m / min and 0.5m respectively, drop the we...

Embodiment 2

[0080] This embodiment mainly simulates the high-temperature corrosion experiment in which various gases coexist in the garbage incineration environment, and specifically includes the following steps:

[0081] Step 1: Turn on the cooling water switch and the power supply of the electric control cabinet, set the temperature raising program in the special control software, and raise the temperature in the heating furnace 19 to 800°C.

[0082] Step 2: Input the ascent speed and ascent distance as 1m / min and 0.5m respectively in the special control software, and lift the weighing device box 10 . The super austenitic stainless steel 254SMO sample 26 is hung on the bottom end of the hanging wire 18 connected to the weighing device 11 . In the dedicated control software, input the descending speed and the descending distance as 1m / min and 0.5m respectively, drop the weighing device case 10, lock and seal the first sealing flange 20 connecting the weighing device case 10 and the furna...

Embodiment 3

[0089] This example mainly simulates the high-temperature corrosion experiment in which various gases and deposited salts coexist in the garbage incineration environment, specifically including the following steps:

[0090] Step 1: Turn on the cooling water switch and the power supply of the electric control cabinet, set the temperature raising program in the special control software, and raise the temperature in the heating furnace 19 to 800°C.

[0091] Step 2: Input the ascent speed and ascent distance as 1m / min and 0.5m respectively in the special control software, and lift the weighing device box 10 . Evenly coat the surface of super austenitic stainless steel 254SMO sample 26 with salt (40% NaCl+40% KCl+10% Na 2 SO 4 +10%K 2 SO 4 ) into the corundum crucible and hung on the bottom end of the hanging wire 18 connected to the weighing device 11. In the dedicated control software, input the descending speed and the descending distance as 1m / min and 0.5m respectively, dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com