High-temperature and high-pressure multi-phase flow dynamic visualization loop corrosion testing apparatus and method thereof

A high-temperature, high-pressure, corrosion testing technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the lack of shear force measurement devices, lack of online corrosion detection means, and inability to monitor the occurrence of corrosion on the surface of test pieces online and corrosion processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

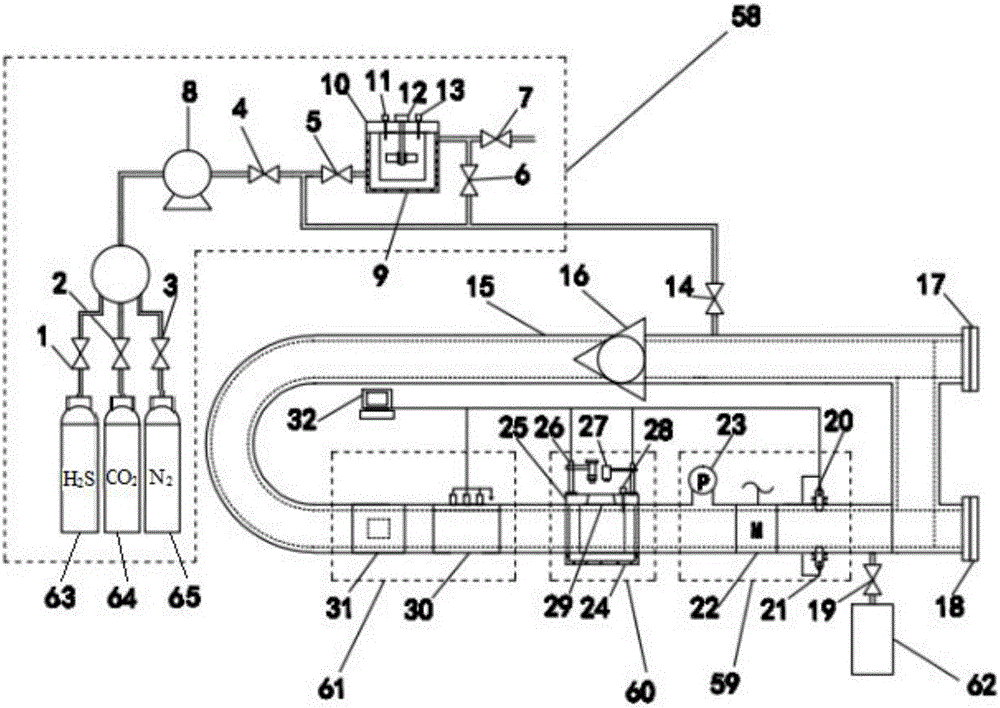

[0061] The invention is used to test the damage effect of multiphase flow acidic corrosive medium on equipment corrosion and erosion under different production conditions, and the experiment process is as follows:

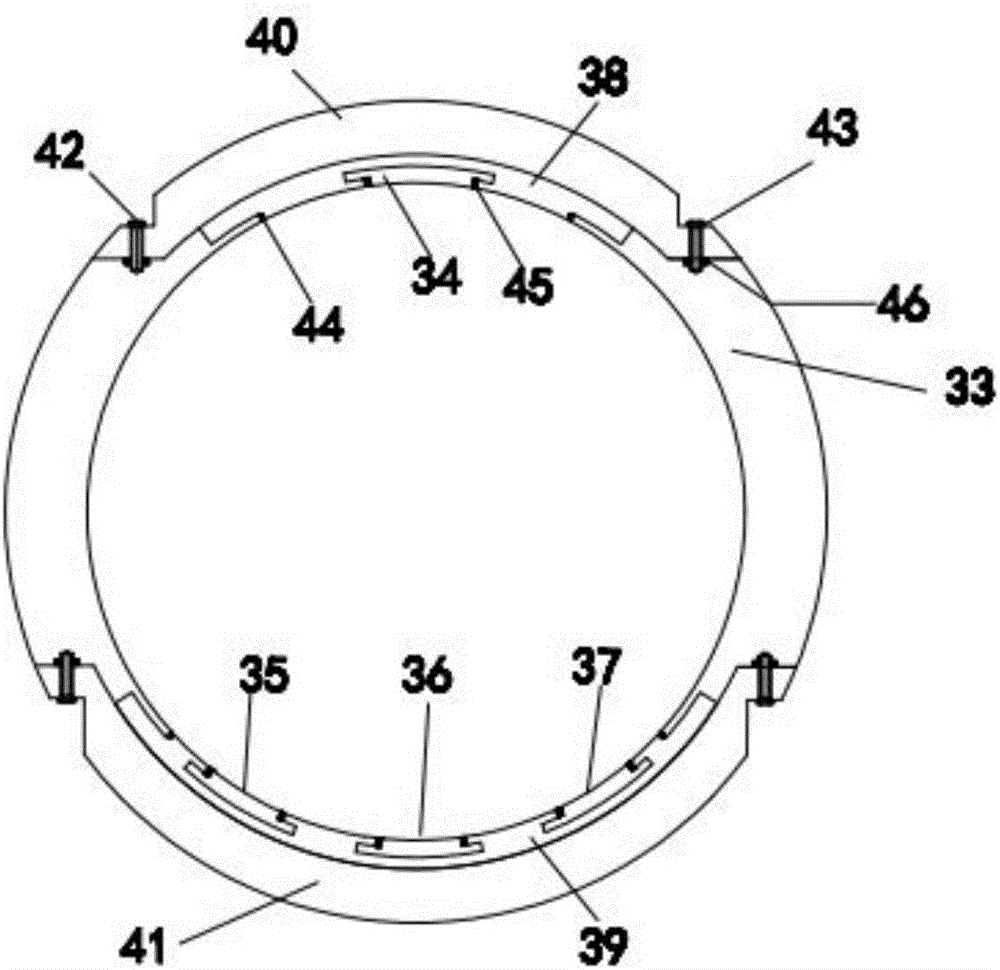

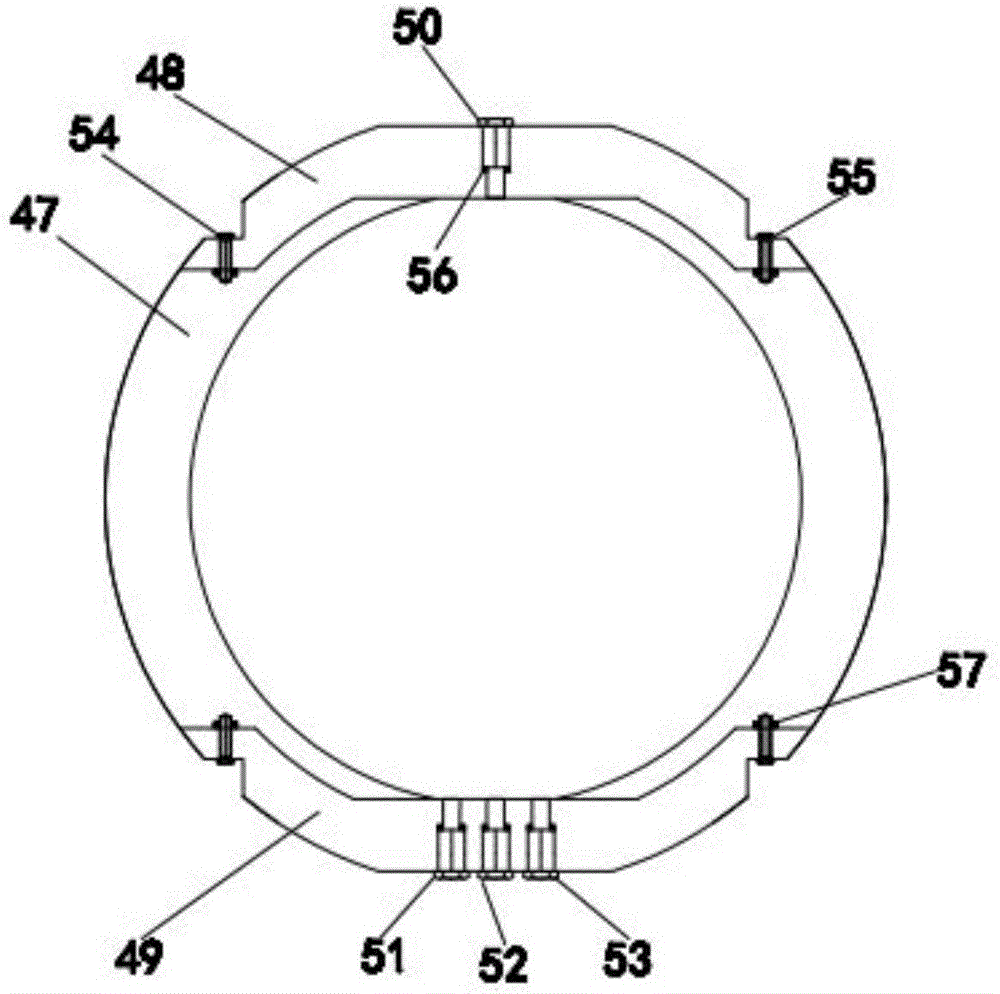

[0062] Step 1: Install 1# arc test piece 34, 2# arc test piece 35, 3# arc test piece 36, 4# arc test piece 37 to corrosion test piece test device 31, inductance resistance probe 50, reference After the comparison electrode 51, the working electrode 52 and the counter electrode 53 are connected to the electrochemical signal detection device 30, the medium displacement unit 58 and the components on the circulation circuit 15 are connected and installed, and debugging is performed;

[0063] Step 2: Open 3# valve 3, N 2 Deoxidize through booster pump 8, 4# valve 4, 5# valve 5, 1# high temperature autoclave body 9, 6# valve 6, 7# valve 7, intake valve 14, circulation loop 15, exhaust valve 19 in turn , The time is 1h, then close the 3# valve 3; inject the liquid phase corros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com