High temperature and high pressure supercritical carbon dioxide uniform corrosion testing system

A carbon dioxide and uniform corrosion technology, which is applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems that parameters such as pressure, flow, and temperature cannot be accurately controlled, and achieve a high degree of automatic protection and ensure uniformity , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

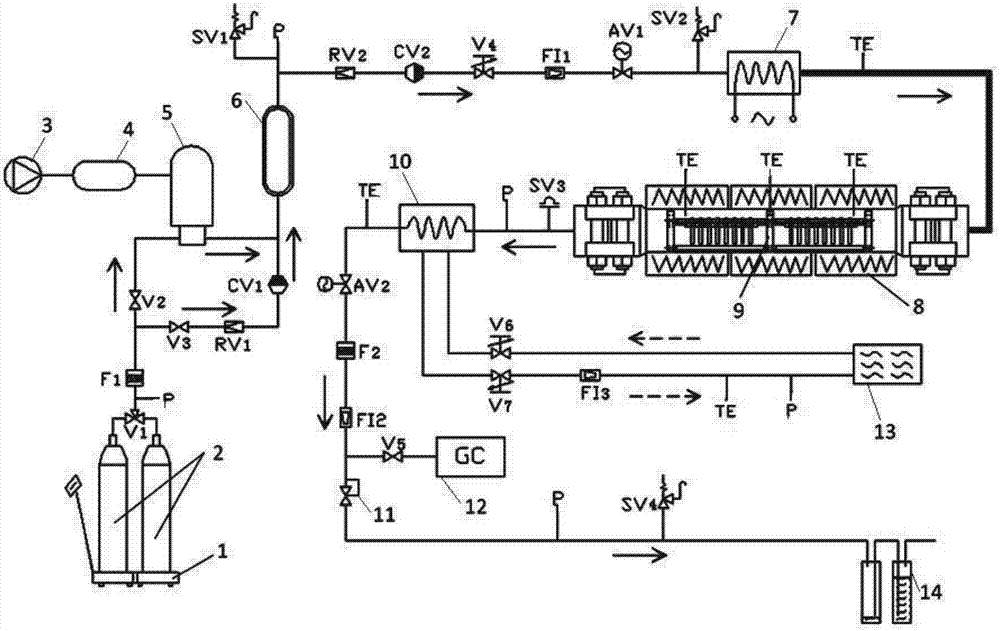

[0030] like figure 1As shown, a high-temperature and high-pressure supercritical carbon dioxide uniform corrosion test system includes a carbon dioxide source, a preheating device 7, a reaction device 8, a condensation device 10, and an exhaust device 14 connected in sequence, and the preheating device 7 is preferably a preheater. The reaction device 8 is preferably a high-temperature and high-pressure reactor, and the condensation device 10 is preferably a condenser. These components can be purchased on the market and are easy to maintain. The condensing device 10 communicates with a circulating cooling system 13 , and a sampling analysis system 12 is provided between the condensing device 10 and the exhaust device 14 , and the sampling analysis system 12 communicates with the pipeline between the condensing device 10 and the exhaust device 14 . In this embodiment, two carbon dioxide storage tanks 2 are placed on the electronic scale 1, and the two carbon dioxide storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com