Test method for simulating couple corrosion in seawater scouring environment

A technology for galvanic corrosion and testing methods, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., and can solve the problems of galvanic corrosion test methods and technical equipment, and sink type scouring. Equipment and other issues, to achieve the effect of simple and reliable test principle, improved test device and process, good calculation and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

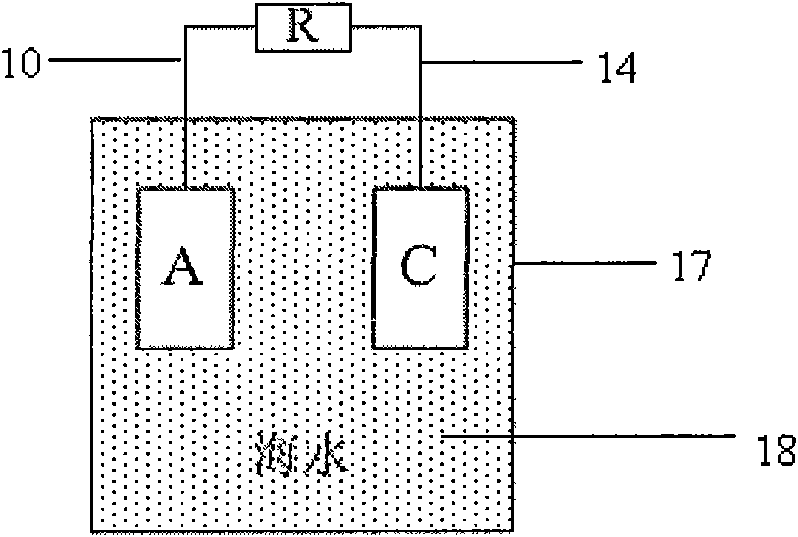

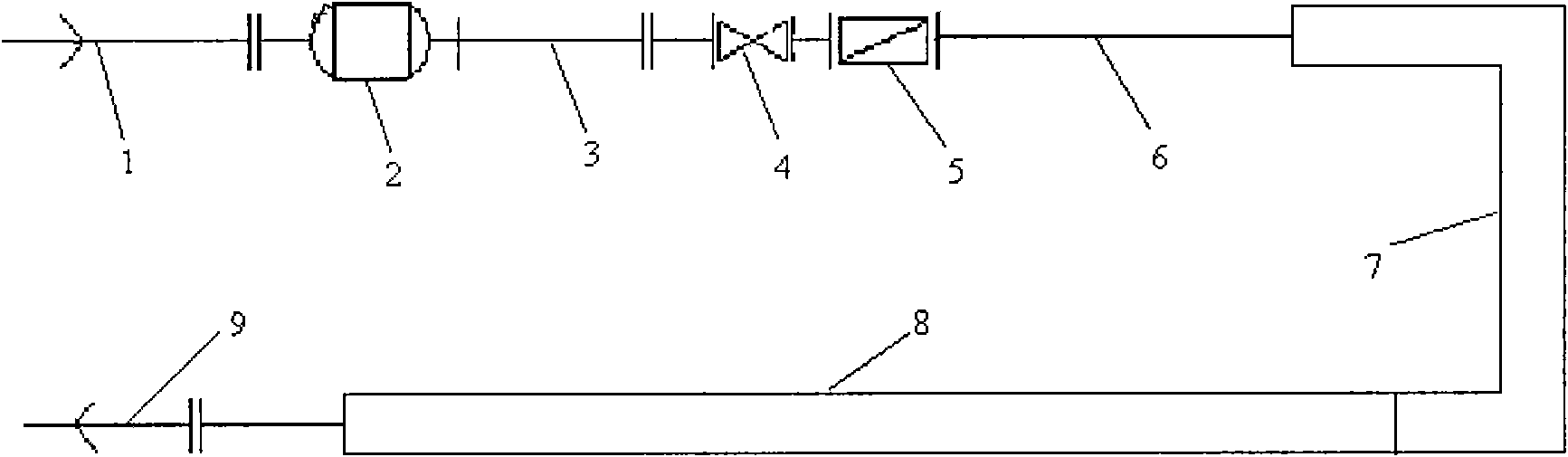

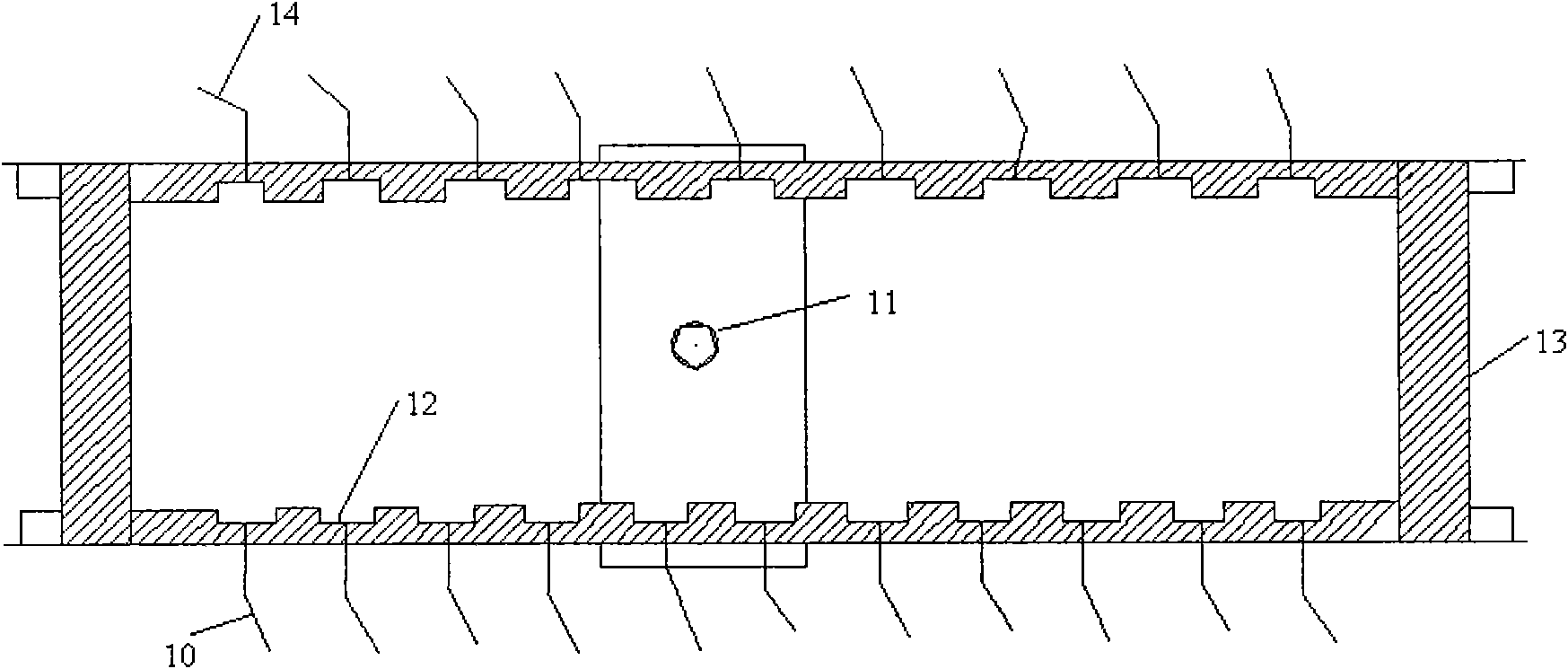

[0016] Each split structure of the test device system used in this embodiment includes a test sample anode A, a test sample cathode C, a resistance module R, a seawater inlet 1, a seawater pump 2, a flexible pipe 3, a ball valve 4, and a flow meter 5 , PVC pipe 6, flowing water tank 7, test tank 8, seawater outlet 9, wire 10, reference electrode 11, sample card slot 12, PVC support bar 13, wire 14, reference electrode SCE15, PVC support bar 16, The flow-type test tank 17 and seawater 18 are combined and connected in principle at each test stage respectively to form a flow-type tank scouring corrosion test device; the implementation of this embodiment first introduces seawater 18 from the water storage tank through the seawater inlet 1 by the seawater pump 2, The seawater 18 enters the flowing water tank 7 through the flexible pipe 3, the ball valve 4, the flow meter 5 and the PVC pipe 6, and then flows into the water storage tank through the seawater outlet 9, so as to realize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com