Method for detecting oil separation degree of integrated cooker

A technology of grease separation and detection method, which is applied in the direction of weighing by removing certain components, can solve the problems of large error in detection results, large volume and weight, high cost, etc., achieve small error in detection results, and improve the test device , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

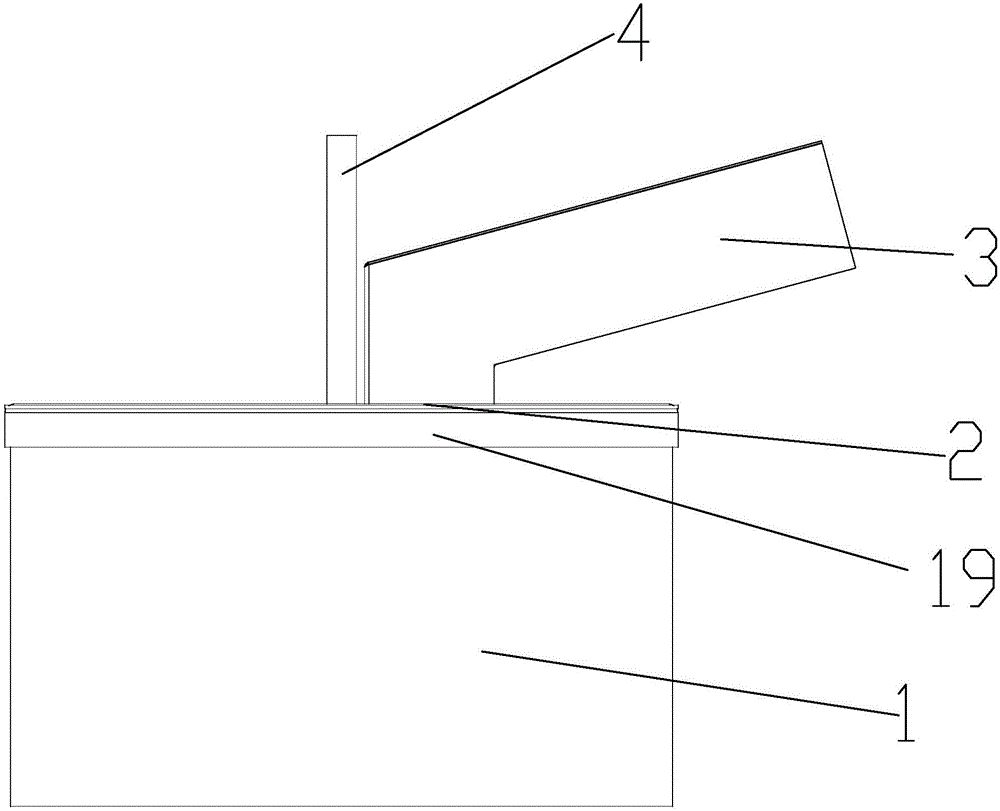

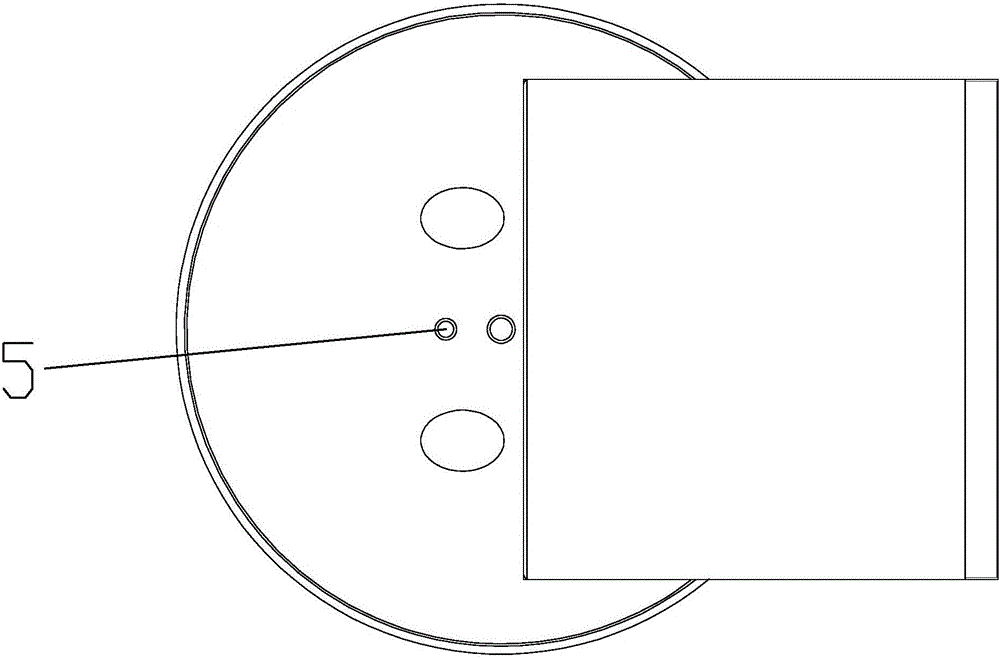

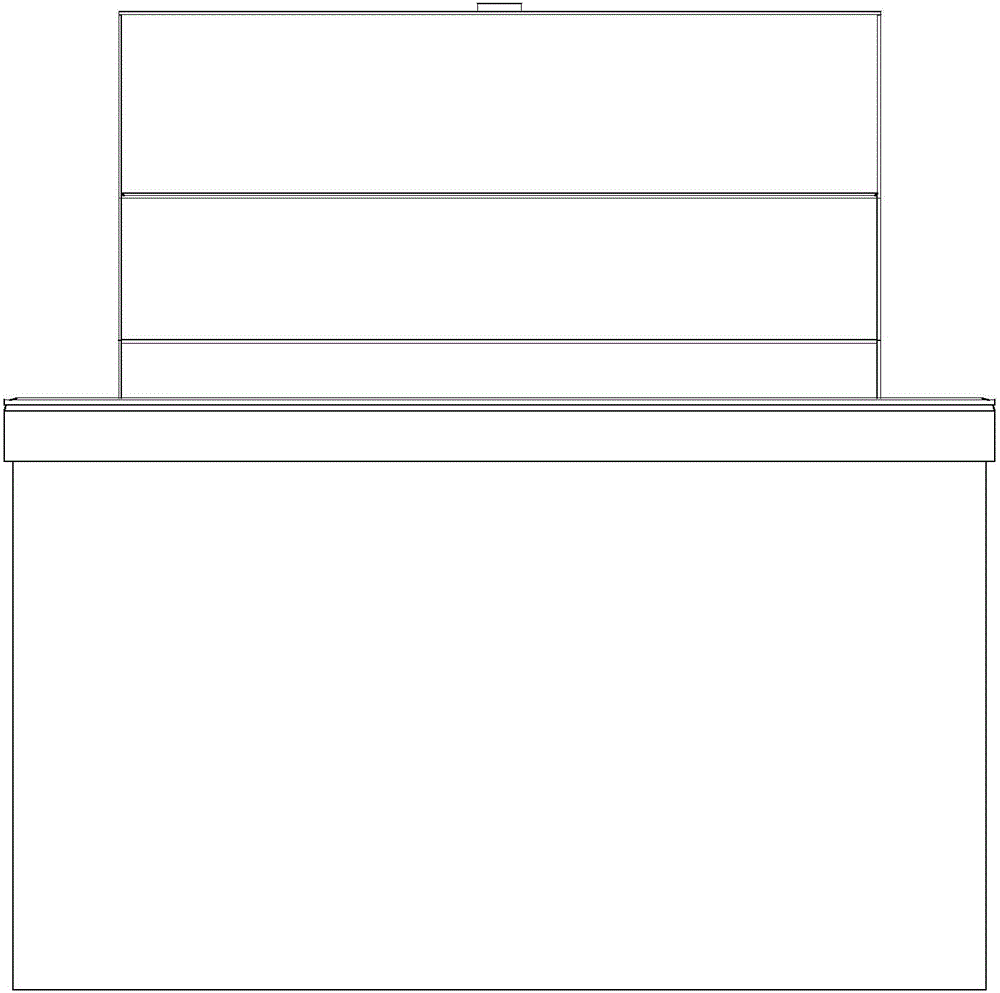

[0028] The detection method of the oil separation degree of the integrated cooker of the present invention is completed by an improved integrated cooker system. The integrated cooker system includes an integrated cooker 14 and a built-in test pot. The test pot includes a test oil pot 1 and a test oil pot 1. A fume shield 2 is installed on the upper part of the fume generator. In order to enhance the sealing performance of the fume generator, the fume shield 2 adopts a closed fume shield, and a sealing ring 19 is arranged on the fume shield 2; A smoke spray pipe 3 and a water drip pipe 4 are installed, the ends of the smoke spray pipe 3 and the water drip pipe 4 are inserted into the closed oil fume shield 2, and a thermostat probe socket 5 is provided between the smoke spray pipe 3 and the water drip pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com