High-temperature high-pressure multiphase flow corrosion testing method and device

A technology of high temperature and high pressure, corrosion experiment, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., it can solve the problems of increasing speed error, inability to simulate field conditions, and inability of corrosive medium to realize pipeline flow, etc. The effect of reliable and stable experimental method on corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

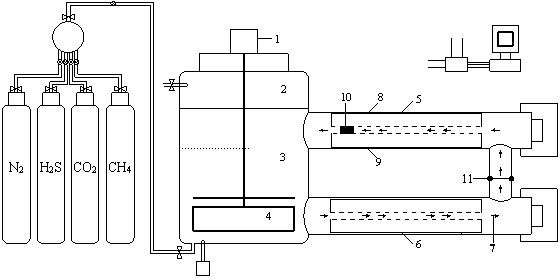

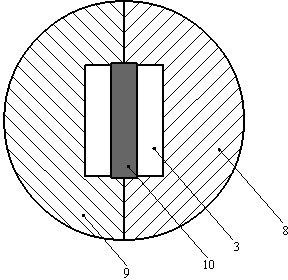

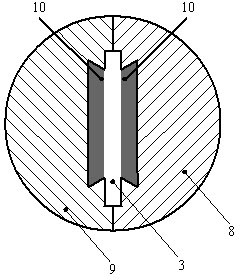

[0024] refer to figure 1 As shown, a high temperature and high pressure multiphase flow corrosion experiment device in the present invention, the main shaft motor 1, the kettle cover 2, the corrosive medium 3, the stirring blade paddle 4, the upper branch pipe 5 of the kettle body, the lower branch pipe 6 of the kettle body, the flow direction of the corrosive medium 7. Upper insulating fixture 8, lower insulating fixture 9, sample 10, ultrasonic flowmeter 11, insulating spacer 12, clamping groove 13; the spindle motor 1 drives the stirring blade 4 to rotate to realize the corrosive medium according to the corrosive medium Flow in the direction shown in the flow direction 7, and simulate the experimental flow rate through the size of the rotating speed; after the upper insulating fixture 8 and the lower insulating fixture 9 are combined, they can be smoothly loaded into the upper branch pipe 5 of the kettle body and the lower branch pipe 6 of the kettle body; The sample 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com