Combined-loading stress corrosion testing apparatus and method

A stress corrosion and composite loading technology, applied in measuring devices, using stable torsion to test material strength, and using stable tension/pressure to test material strength, etc. problem to improve the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0031] The test device designed in the present invention can realize the stress corrosion test under the compound loading condition of simultaneously bearing three kinds of forces of tension, torsion and fluid flow impact, the principle is simple, the operation is convenient, and it is closer to the actual working conditions of the oil field, which is conducive to promoting Research on stress corrosion of drill pipe and casing materials in oil and gas fields under real stress conditions.

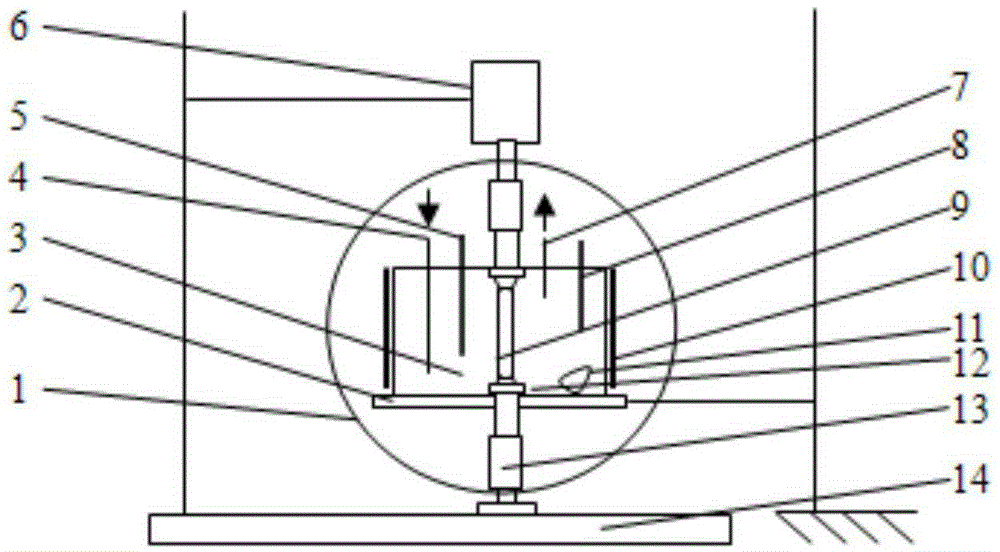

[0032] Such as figure 1 As shown, the test device of the present invention includes an environmental container 3, a tension ring 1, an electromagnetic stirrer 2, a rotating motor 6, a heating jacket 10, an air inlet pipe 4, an air outlet pipe 7, a thermocouple 5, a pressure sensor 8, and Support 14. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com