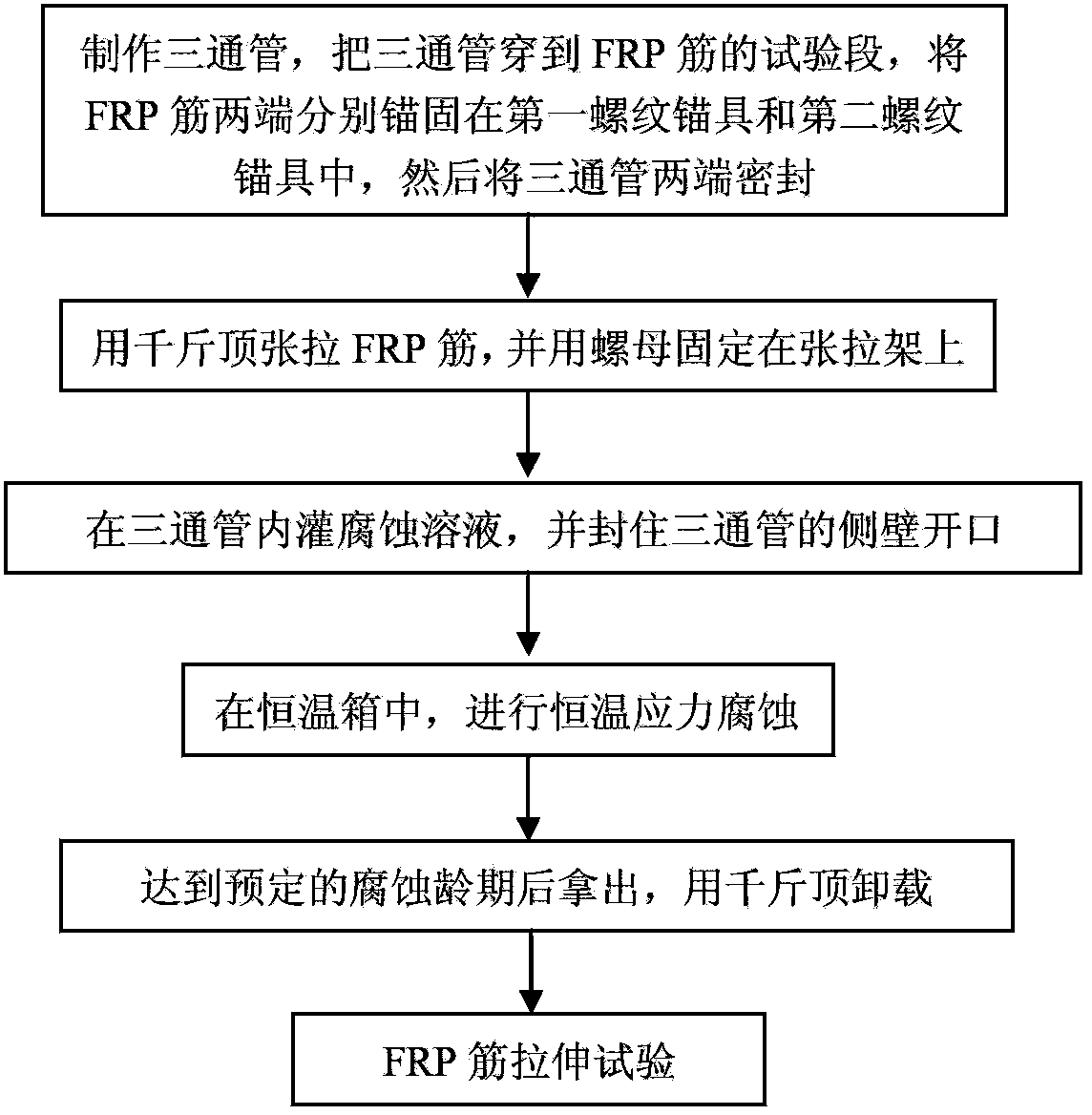

Constant-temperature stress corrosion testing device and method for FRP (fiber reinforced polymer) tendon

A stress corrosion and test device technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of long test period, difficult to move, difficult to control constant temperature, etc., to achieve the effect of simple structure and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

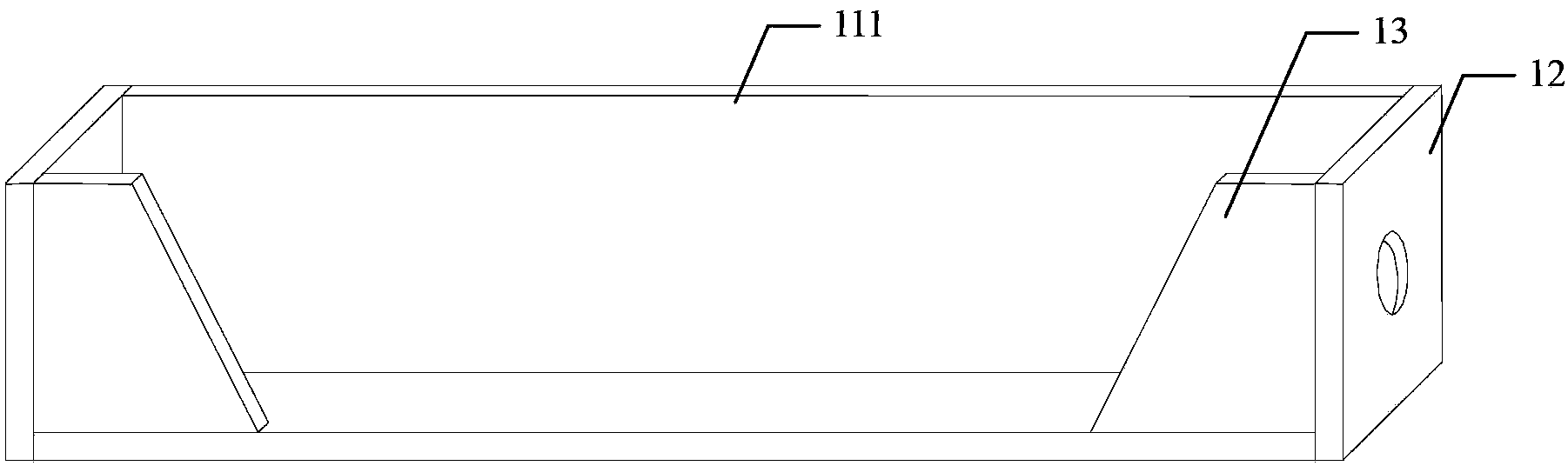

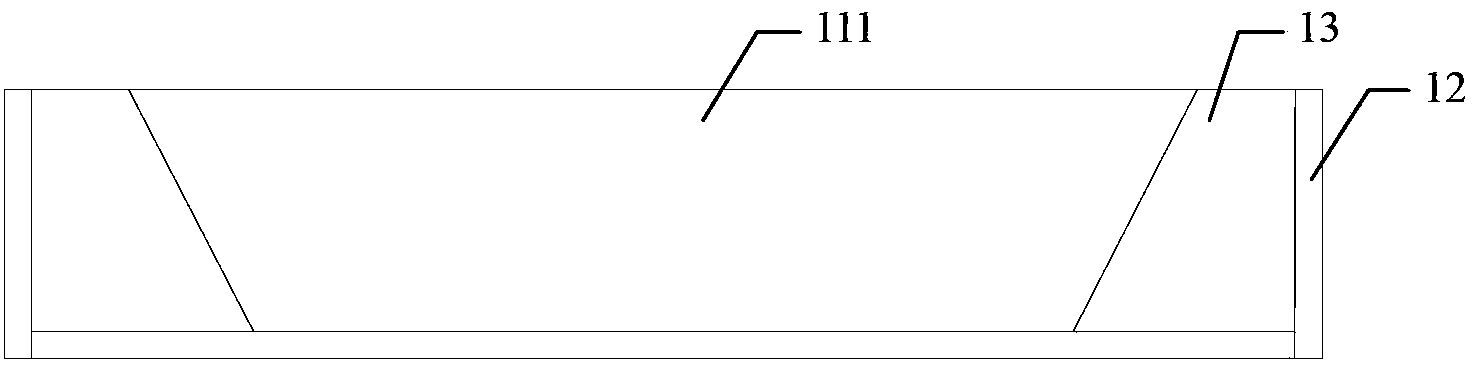

[0041] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the FRP tendon constant temperature stress corrosion test device of the present invention includes a tension frame 1, a first threaded anchor 31, a second threaded anchor 32, a tee pipe 4, a spring 6, a third end plate 7, and a reaction frame 8. Jack 10, force sensor 11 and tension anchor 12.

[0042]Wherein, the tension frame 1 includes a support rod 111 , a first end plate 121 , a second end plate 122 and a reinforcing plate 13 . The tensioning frame 1 of the present invention is used to provide the reaction force during the tensioning process, and keep the stress level of the FRP tendon constant during the long-term test process, and has sufficient rigidity and bearing capacity. The tension frame 1 is made of steel, and each part is assembled by welding. The specific dimensions and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com