Intermittent immersion corrosion test method and device based on slow tensile stress corrosion testing machine

A corrosion test and tensile stress technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, using stable tension/pressure to test the strength of materials, etc., can solve the problem of not being able to simulate the immersion environment in the tidal range and unable to characterize materials Stress corrosion sensitivity and other issues, to achieve the effect of ensuring long-term stable operation, simple structure, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Since the test method of the present invention is implemented using the infiltration device of the present invention, the specific implementation of the infiltration device will be described first.

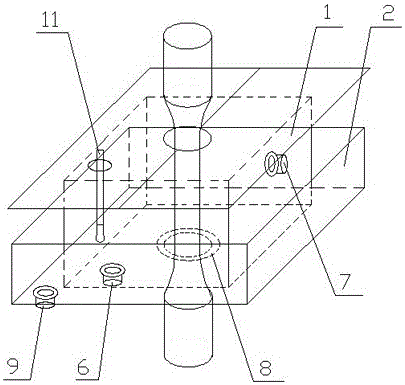

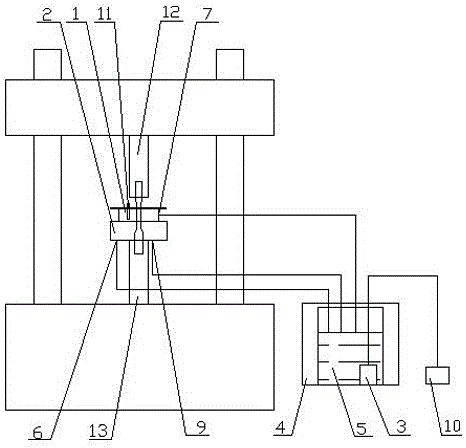

[0029] Such as figure 1 and figure 2 As shown, the interleaving device of the present invention includes a corrosion box 1, an overflow box 2, a pump 3, a constant temperature water bath box 4, and a corrosive medium container 5 arranged in the constant temperature water bath box 4; in this embodiment, the pump 3 adopts a submersible pump , directly arranged at the bottom of the corrosion medium container 5, avoiding the leakage of the corrosion medium and creating a good test environment; the bottom surface of the corrosion box 1 is provided with a sample hole, and the sample hole is set as a tapered hole with a large top and a small bottom, There is a rubber ring 8 for fixing the sample in the tapered hole. The sample hole is set in a tapered shape to make the rubber ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com