Controllable coolant pump

一种冷却剂泵、冷却回路的技术,应用在泵控制、非变容式泵、机器/发动机等方向,能够解决阻碍燃烧室加温、复杂结构、冷却剂流昂贵机械机构等问题,达到结构保持简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

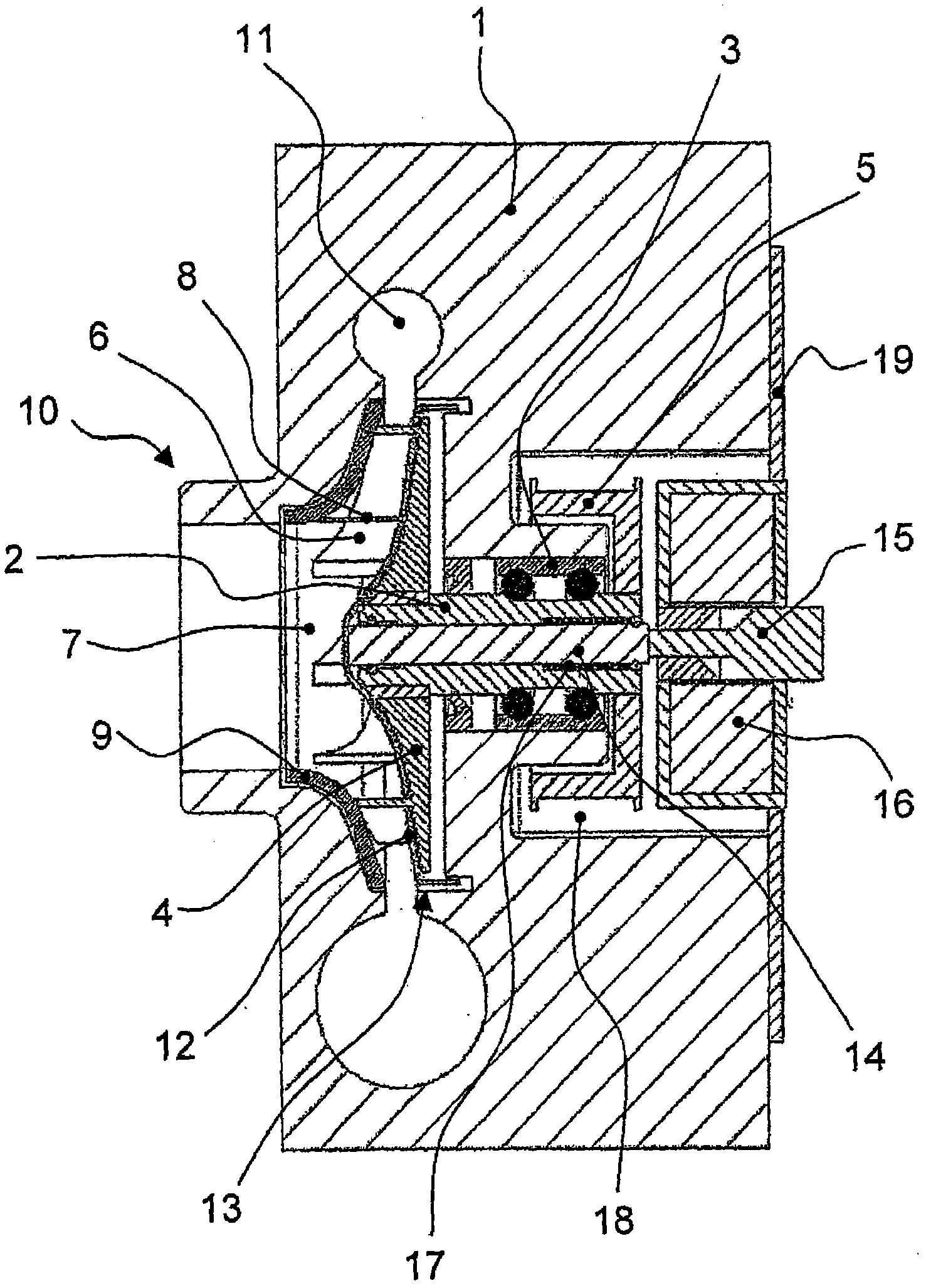

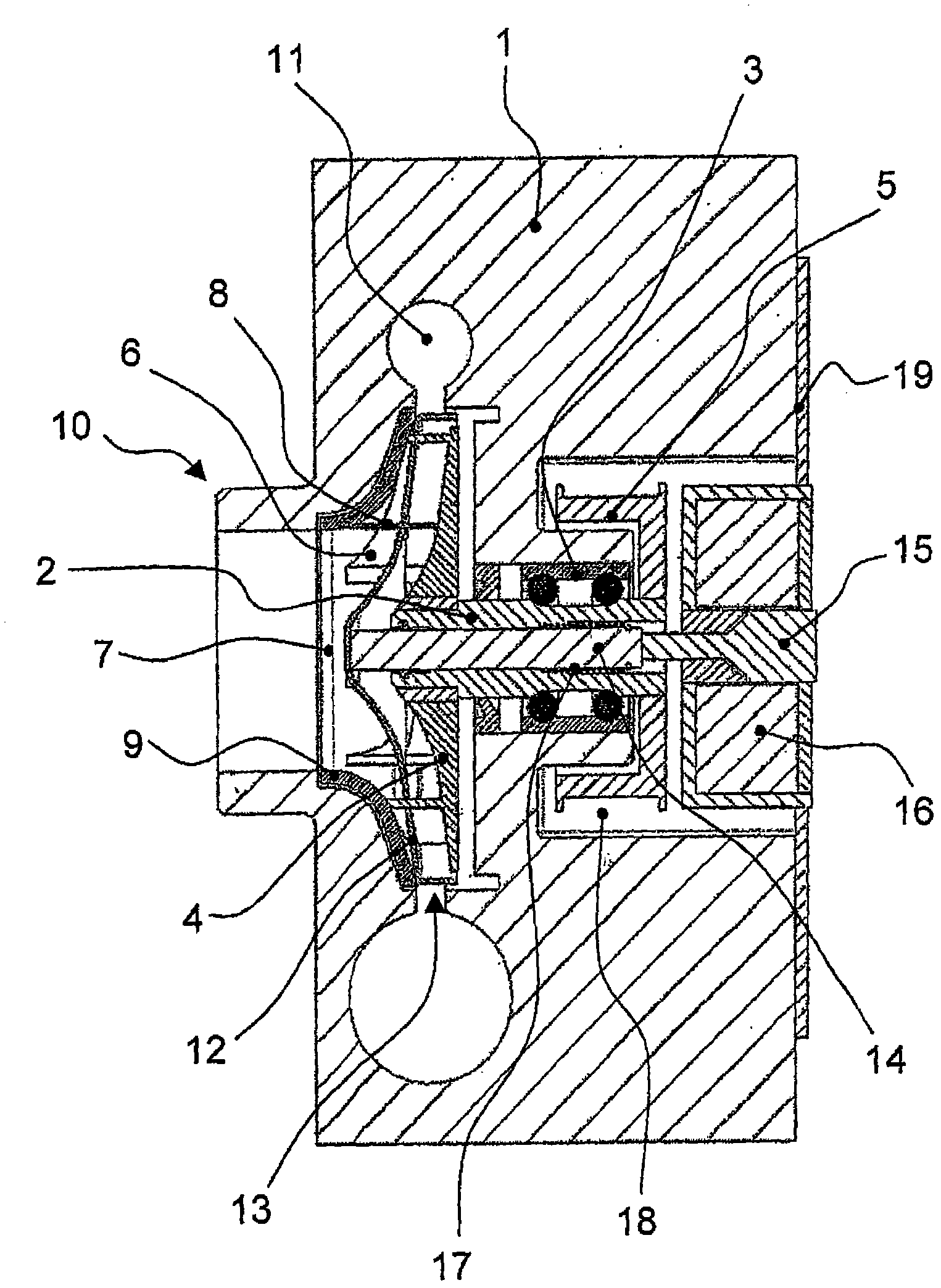

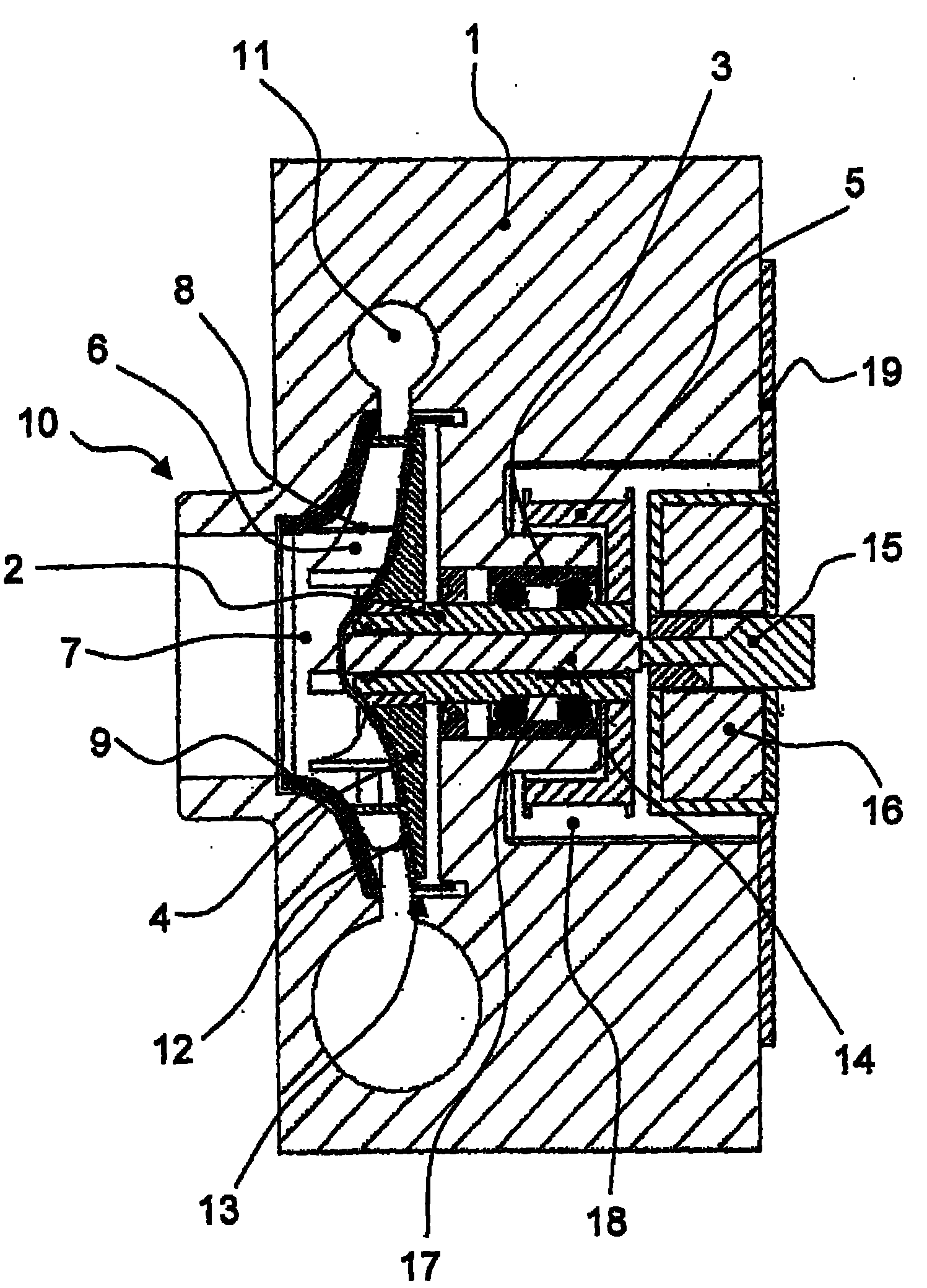

[0021] exist Figure 1a shows a sectional view of a coolant pump according to the invention having a hollow shaft 2 mounted in a pump housing 1 . Here, the hollow shaft 2 is rotatably mounted in a bore of the pump housing 1 via a double row ball bearing 3 and carries an impeller 4 at one end, while the hollow shaft 2 is fixed at its other end with a belt pulley 5 connect. With this pulley 5 the hollow shaft 2 can be driven via a belt drive of the internal combustion engine, not shown here. The impeller 4 has blades 6 which extend axially into a suction chamber 7 of the coolant pump. In addition, the impeller 4 is kept connected to the cover plate 9 via the axial connecting piece 8 . When the coolant pump is in operation, water is sucked into the suction chamber 7 via the suction connection 10 of the pump housing 1 by the joint rotation of the impeller 4 and the cover plate 9 and due to this generated by the impeller 4 and by the blades 6 is pushed into the annular channel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com