High-speed large-torque full-hydraulic top drive well-drilling device

A high-torque, full-hydraulic technology, applied in the field of high-speed, high-torque full-hydraulic top drive drilling devices, can solve problems such as increased cost, poor versatility of drive motors, small top drive speed adjustment range, and small torque range to reduce vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

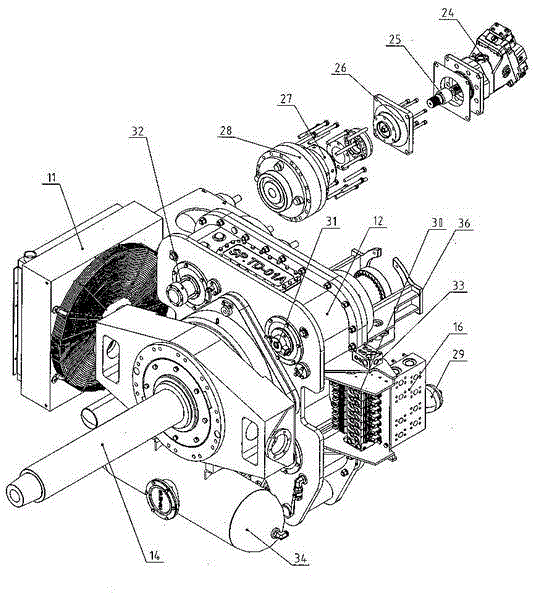

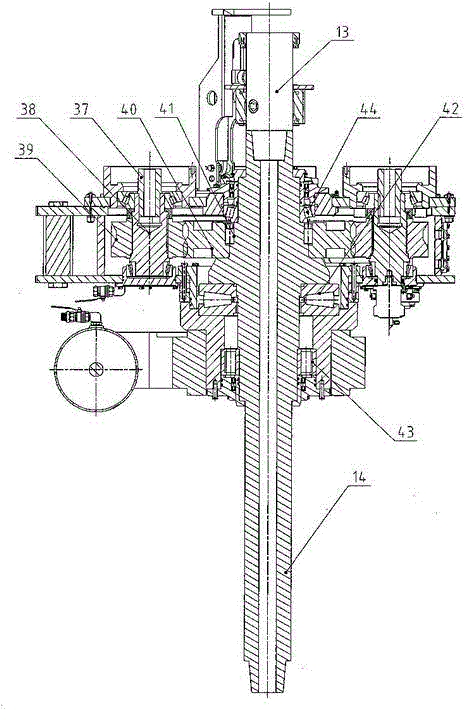

[0032] The present invention is driven by a variable high-speed, small-torque oblique-axis axial plunger hydraulic motor, and the planetary reducer and the main transmission box reduce the speed and increase the torque, thereby realizing a reasonable torque and speed range for driving the drill string to rotate. The fully hydraulic top drive uses an independent diesel-electric hybrid drive hydraulic power unit as the hydraulic oil source. The main power element of the hydraulic system is a variable swash plate axial piston hydraulic pump, and the auxiliary power element is a load-sensitive axial piston hydraulic pump. The main hydraulic system of the hydraulic top drive adopts a closed volume speed regulation circuit, and the auxiliary functions adopt each open circuit constructed by a load-sensitive multi-way valve.

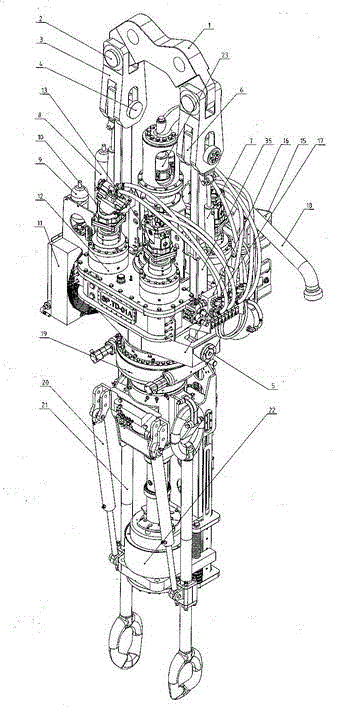

[0033] like figure 1 As shown, the present invention is made up of hoisting device 1, main transmission box 12, hydraulic chuck 22, swivel head 19, manual and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com