Fluorine-free super-hydrophobic fabric as well as preparation method and application thereof

A super-hydrophobic, fabric technology, applied in textiles and papermaking, general water supply saving, plant fibers, etc., can solve the problems of cumbersome preparation process of super-hydrophobic fabrics, achieve excellent oil spill cleanup and oil-water separation performance, easy to operate, easy to scale The effect of scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A first aspect the present invention provides a fluorine-free method for preparing a superhydrophobic fabric, comprising the steps of:

[0032] Sl, acrylic 3- (trimethoxysilyl) propyl methacrylate and long chain silane uniformly dispersed in anhydrous ethanol to obtain a solution A;

[0033] S2, the PEI solution is uniformly dispersed into the above solution A to obtain a solution B;

[0034] S3, the hydrophilic silica nanoparticles uniformly dispersed in the above solution B, C to obtain a mixture;

[0035] S4, the fabric is modified by the mixed liquid C to give a superhydrophobic fluorine-free fabric.

[0036] The present invention is by reaction of 1,4-conjugate addition to PEI and implemented (acrylate, 3- (trimethoxysilyl) propyl) TMSPA multifunctional covalent crosslinking between and by hydrogen bonding between the fabric and the PEI interaction of the fabric in situ modification; simultaneous action TMSPA and silanated long-chain silane is commonly connected to the...

Embodiment 1~5

[0052] Preparation method of a fluorine-free wavefrotic cotton fabric, including the steps of:

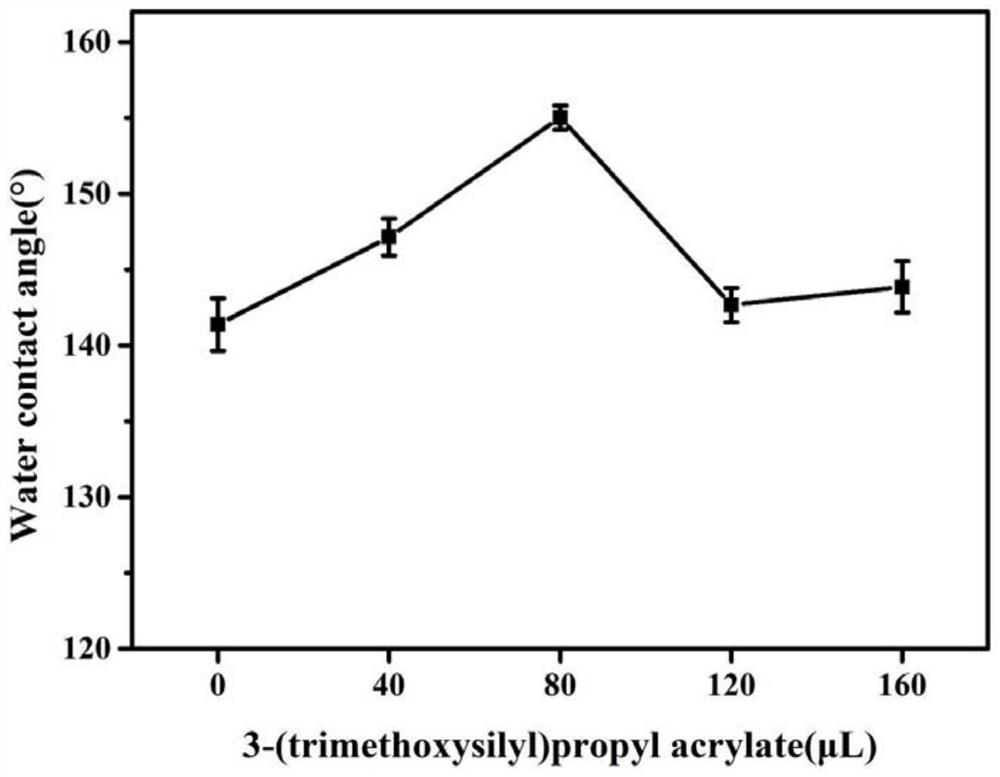

[0053] (1) 80 μL of acrylic 3- (trimethoxilica) propyl ester and 400 μL of dodecyltrimethoxysilane were dispersed in 20 ml of anhydrous ethanol;

[0054] (2) In the stirring state, 20 ml 10 mg / ml PEI aqueous solution was added to the solution of step (1);

[0055] (3) 0.4 g of hydrophilic silica nanoparticles were added to the above-mentioned mixed solution for 5 min;

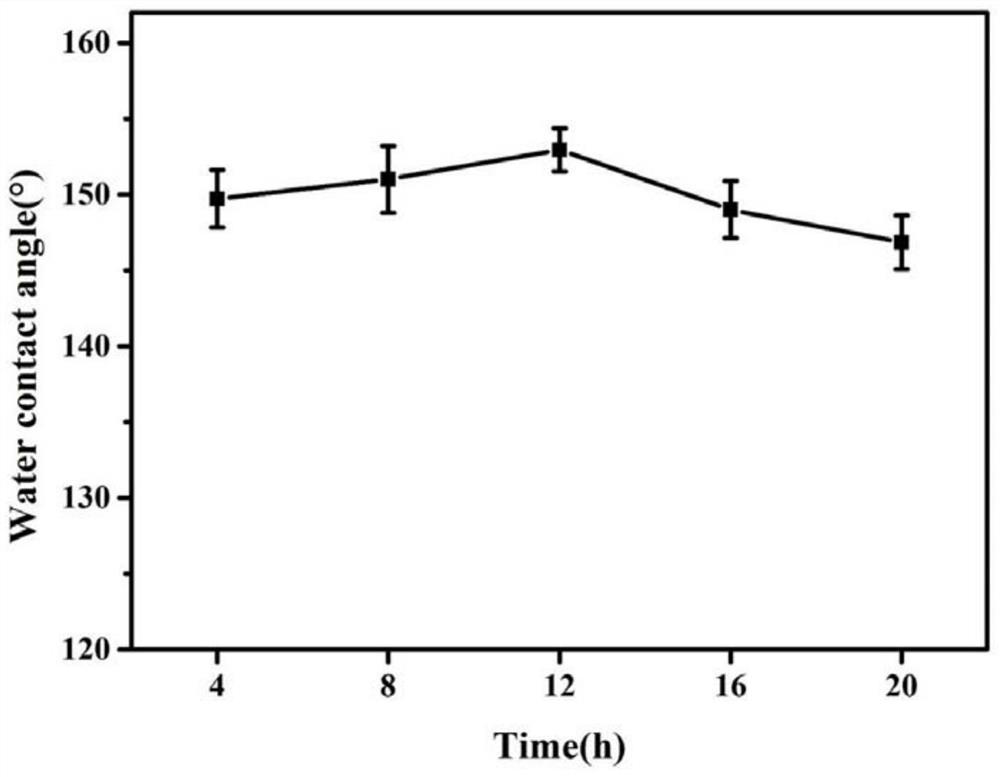

[0056] (4) Washing cotton fabric obtained by ultrasound to ethanol and dried over, dried through the wiper cotton fabric, and stirred in the solution of step (3), stirring 4, 8, 12, 16, 20h, temperature 25 ° C, rotation speed is 500 rpm , Remove the modified cotton fabric is dried in an oven at 80 ° C to give a fluorine-free coastal cotton fabric.

[0057] The water contact angle of the modified cotton fabric was prepared from 149.7 °, 151.0 °, 152.9 °, 149.0 °, 146.8 °, respectively.

Embodiment 6~10

[0059] Preparation method of a fluorine-free wavefrotic cotton fabric, including the steps of:

[0060] (1) 80 μL of acrylic 3- (trimethoxilica) propyl ester and 400 μL of dodecyltrimethoxysilane were dispersed in 20 ml of anhydrous ethanol;

[0061] (2) In the stirring state, 20 ml 10 mg / ml PEI aqueous solution was added to the solution of step (1);

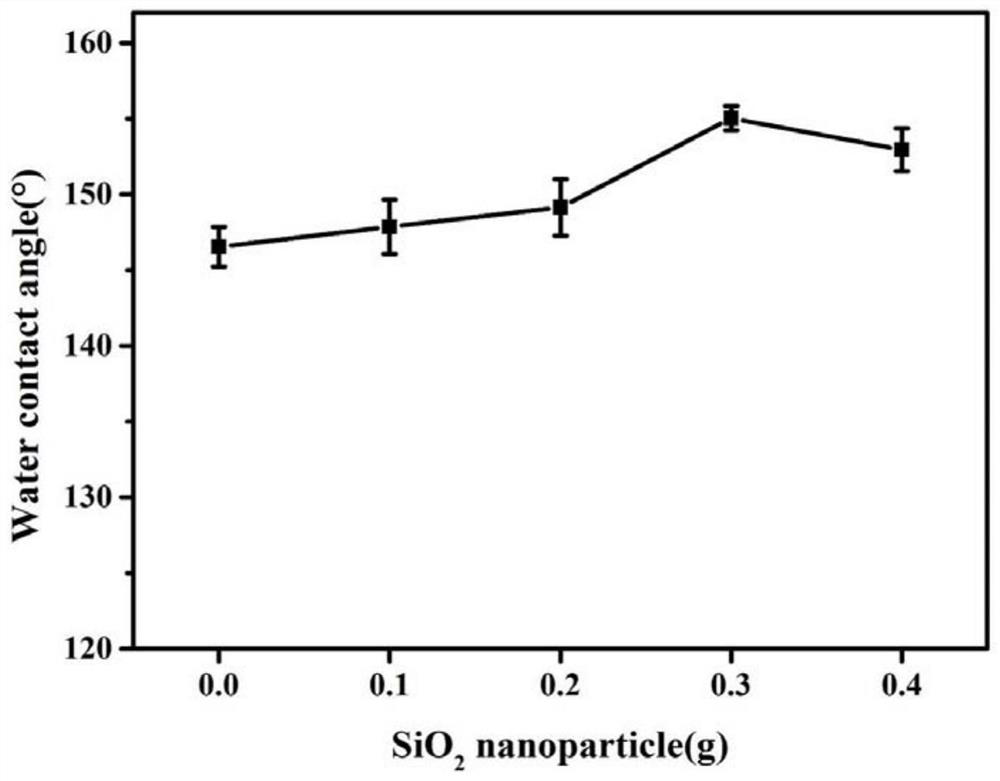

[0062] (3) 0, 0.1, 0.2, 0.3, 0.4 g of hydrophilic silica nanoparticles were added to the above mixed solution for 5 min;

[0063] (4) Washing the past ionized water and ethanol, 10 min and dried a clean cotton fabric is placed in the solution of step (3), stirring for 12 h, temperature 25 ° C, rotational speed is 500 rpm, and the modified cotton fabric is taken out Drying in an oven at 80 ° C to give a fluorine-free wafted cotton fabric.

[0064] The water contact angle of the modified cotton fabric was prepared from 146.5 °, 147.8 °, 149.1 °, 155.0 °, 152.9 °, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| oil-water separation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com