Mixed biomass briquette fuel and forming method thereof

A molding fuel and biomass technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of large wear of molding molds and pressure rollers, unfavorable continuous use of equipment, and difficult oil residue treatment, etc., to achieve low equipment loss, It is convenient for large-scale continuous production and the effect of small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

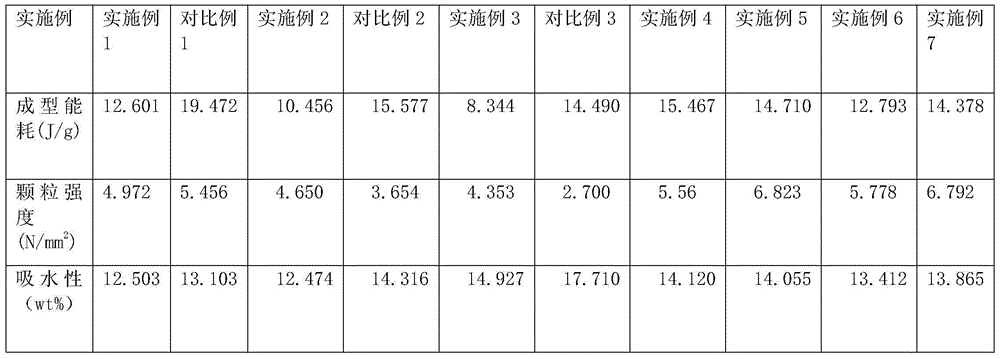

Examples

Embodiment 1

[0039] In this embodiment, castor bean fruit processing waste and fir wood chips are mixed and pressed into molding, and the molding method includes the following steps:

[0040] (1) Raw material pretreatment: Put the cedar wood chips in a constant temperature and humidity box with a temperature of 20°C and a humidity of 90% for 2 weeks, and then dry them at 40°C to a moisture content of 10%. After sieving, the raw materials of fir wood chips with a particle size of not more than 2mm are selected;

[0041] Dry the castor fruit processing waste at 40°C to a moisture content of 5%, pulverize it with a pulverizer, and sieve to screen out the castor fruit processing waste raw materials with a particle size of not more than 2mm;

[0042] (2) Mixing and molding: the fir wood chips and castor fruit processing waste materials obtained in step (1) are mixed and stirred at a mass ratio of 1:1, and 3% of the dry mass of castor fruit processing waste residues is added. Quicklime is used to adju...

Embodiment 2

[0050] In the present embodiment, the processing waste of smooth skin fruit and camphor wood chips are mixed and pressed into a molding, and the molding method includes the following steps:

[0051] (1) Raw material pretreatment: Put camphor wood chips in a constant temperature and humidity box with a temperature of 30°C and a humidity of 70% for 2 weeks, and then dry them at 40°C to a moisture content of 10%, and then It is sieved to screen out camphor wood chips with a particle size of not more than 2mm;

[0052] Dry the peeled fruit processing waste at 40°C to a moisture content of 5%, pulverize with a pulverizer, and sieve to screen out the peeled fruit processing waste raw materials with a particle size not greater than 2mm;

[0053] (2) Mixing and molding: the camphor wood sawdust raw material and the raw fruit processing waste raw material obtained by the pretreatment in step (1) are mixed and stirred at a mass ratio of 2:1, and quicklime accounting for 3% of the dry basis of ...

Embodiment 3

[0057] In this embodiment, the Litsea cubeba fruit processing waste and hay cuttings are mixed and pressed into molding, and the molding method includes the following steps:

[0058] (1) Raw material pretreatment: Put the dried grass clippings in a constant temperature and humidity box with a temperature of 20°C and a humidity of 90% for 2 weeks, and then dry them at 40°C to a moisture content of 10%, and then After sieving, the hay cutting raw materials with a particle size of not more than 2mm are selected;

[0059] Dry the Litsea cubeba fruit processing waste at 40°C to a moisture content of 5%, crush it with a pulverizer, and sieve to select the Litsea cubeba fruit processing waste raw materials with a particle size not greater than 2mm;

[0060] (2) Mixing and molding: mix the hay scraps and the raw materials of Litsea cubeba fruit processing waste obtained by the pretreatment in step (1) at a mass ratio of 1:1, and add 3% of the dry basis mass of the Litsea cubeba fruit process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com