Patents

Literature

32results about How to "Facilitate large-scale continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and use of nitrogen-doped carbon-surface-loaded mononuclear metal catalyst

PendingCN106784871AExcellent catalytic ORR activityImprove stabilityCell electrodesPtru catalystCarbonization

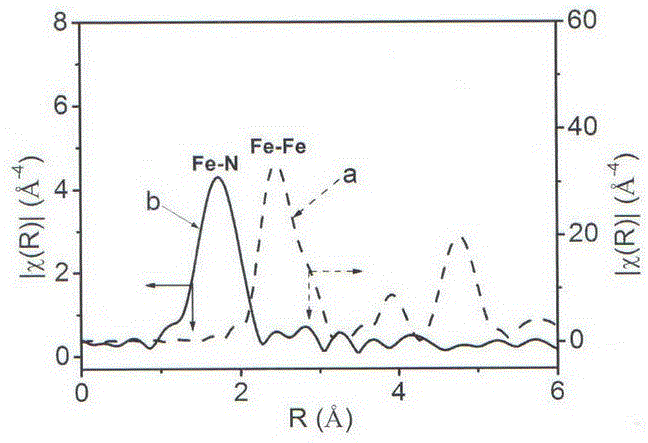

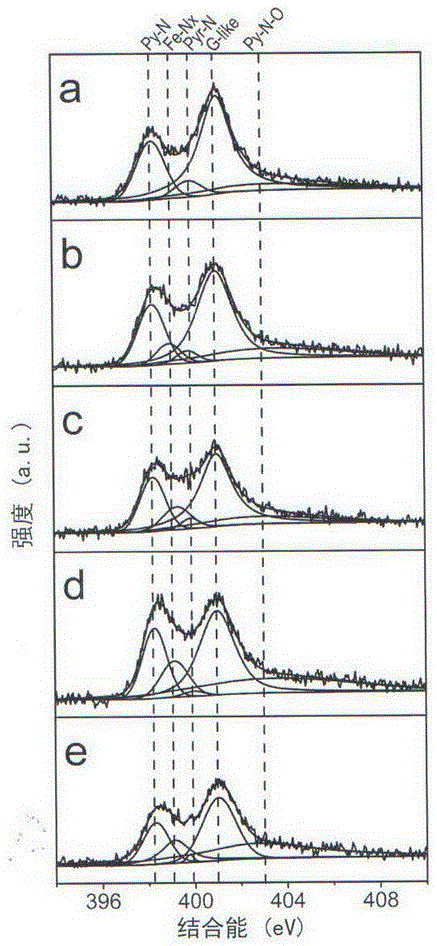

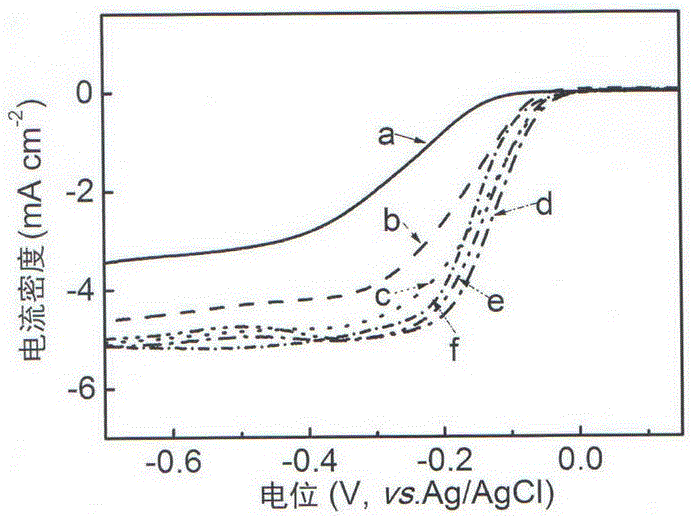

The invention discloses a preparation method and a use of a nitrogen-doped carbon-surface-loaded mononuclear metal catalyst. The preparation method comprises the steps of loading transitional metal salt on the surface of silicon dioxide by an impregnation method, drying and then dispersing into ethylenediamine and carbon tetrachloride solution, and performing refluxing treatment; and performing high-temperature roasting and carbonizing on an obtained black material in a protective atmosphere, and then removing silicon dioxide by hydrofluoric acid to obtain the nitrogen-doped carbon-surface-loaded mononuclear metal catalyst (M / NC, M is Fe, Co, Ni, Cu). The prepared catalyst is relatively large in specific surface area, and relatively high in activity and stability; according to the method, the components and the nanostructure are controllable, so that high probability is provided for a large-specific-surface-area and high-durability oxygen reduction electro-catalytic material; the method is simple and easy to implement, and the cost is low; and the catalyst represents extremely high catalytic performance in an electrochemical oxygen reduction reaction, and has high industrial application prospect.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

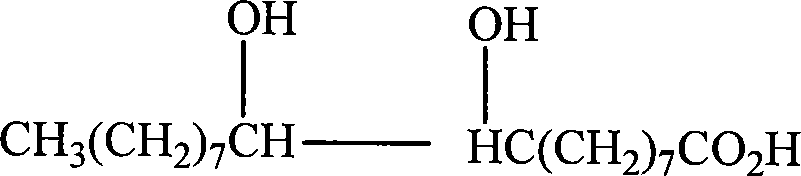

Method for preparing 9,10-dihydroxystearic acid and its methyl by hydrogen dioxide oxidation process

InactiveCN101177392AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationCalcium formate

The invention relates to a preparation method for 9, 10-dihydroxy stearic acid and methyl ester, which is characterized in that the oleic acid and the formic acid are mixed uniformly in room temperature; the mixture is added with hydrogen peroxide, and warmed up and separated from water phase; the solvent is recycled through decompression and distillation; the generative reaction admixture is recrystallized with organic solvent, so that the product 9, 10-dihydroxy stearic acid is prepared. The recovered formic acid solution can generate ice-cream calcium formate salt separation by adding calcium oxide and calcium carbonate; subsequently the methyl alcohol and oil of vitriol is arranged into the product 9, 10-dihydroxy stearic acid for a reflux reaction, and then is rotated and vaporized out the water phase and oil phase for being washed to be neutral, thereby the 9, 10-dihydroxy stearic acid methyl ester product is generated through dehydration. The invention has the advantages of clean process, safe implementation, easy operation, full utilization of the reactant, reduced waste emission, effective utilization of the low-concentration hydrogen peroxide, and favorableness to large-scale production.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

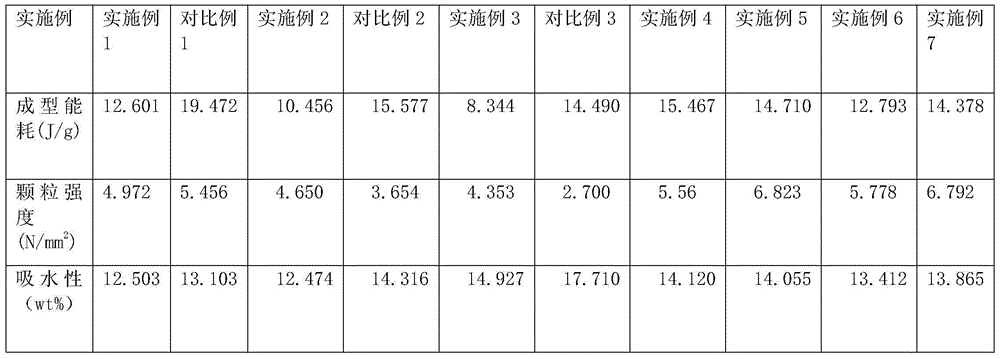

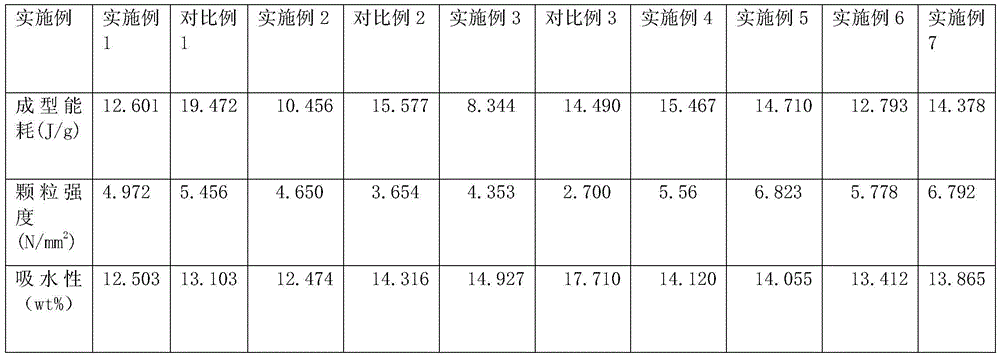

Mixed biomass briquette fuel and forming method thereof

InactiveCN103602359ARealize resource utilizationResolve disposal issuesBiofuelsSolid fuelsCelluloseHybrid type

The invention relates to a mixed biomass briquette fuel and a forming method thereof. The mixed biomass briquette fuel is prepared by mixing a mixture of an oil plant fruit squeezed cake or an oil plant fruit squeezed cake and an oil plant fruit oil-cracked solid-phase product with cellulose type biomass scrap, pressing and forming. The forming method comprises the following steps: (1) pretreatment of raw materials; and (2) mixing and forming to obtain the mixed biomass briquette fuel. The mixed biomass briquette fuel provided by the invention has high burning rate, and can solve the disposal problem of oil plant fruit processing wastes and waste materials; the forming method has the advantages of low energy consumption in forming process, small equipment loss, and is convenient for large-scale continuous production and convenient for transportation and preservation; the strength is high, and the transportation and the use are convenient; the forming method of the mixed biomass briquette fuel, provided by the invention, can realize deep utilization of industrial oil wastes, and utilize the oil wastes to optimize a production process of biomass fuel and has the advantages of low pollution, low investment and small equipment loss and is simple to operate, and large-scale production is easy to carry out.

Owner:湖南欣林生物油脂工程技术有限公司

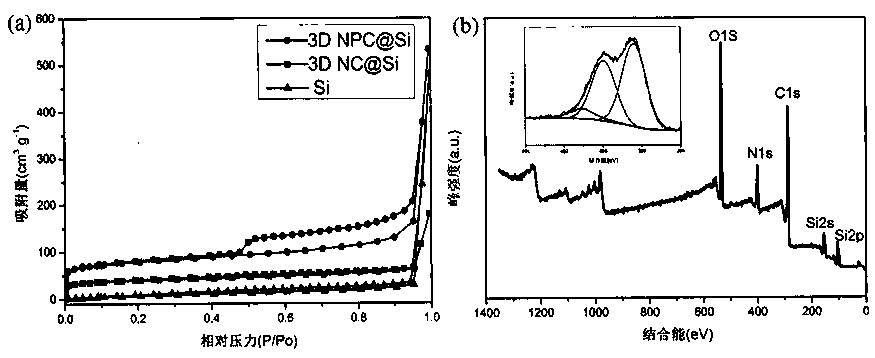

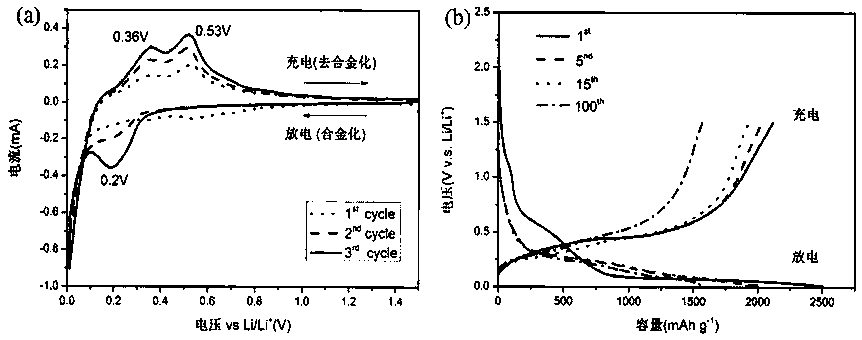

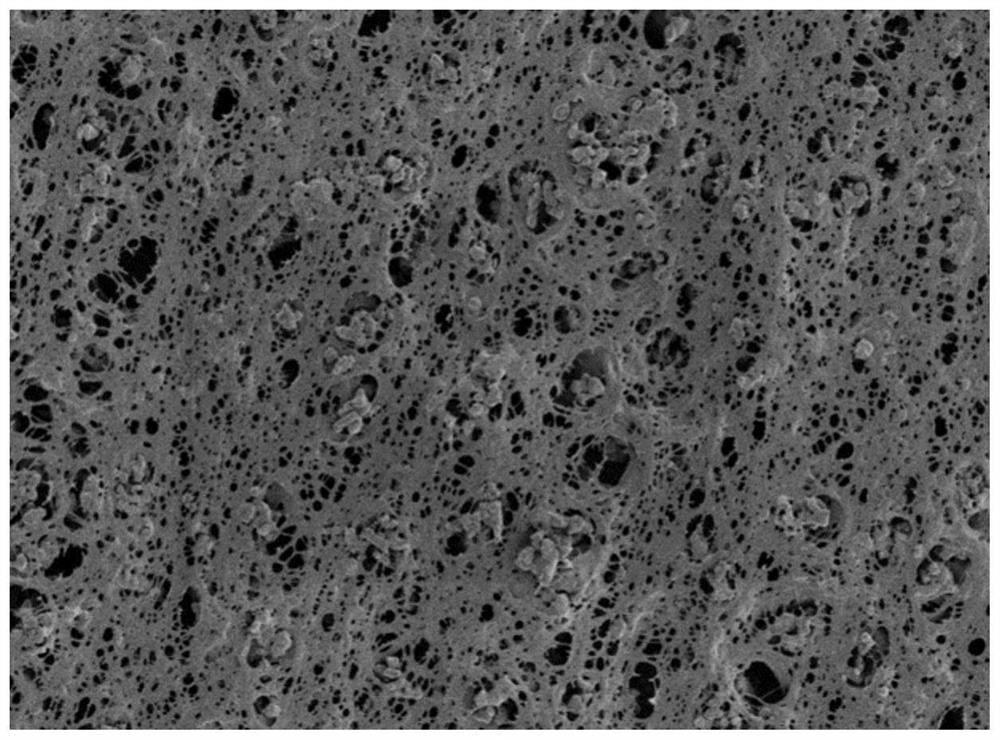

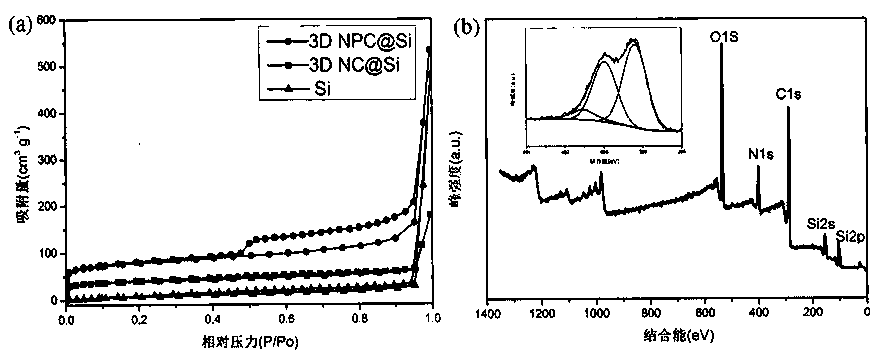

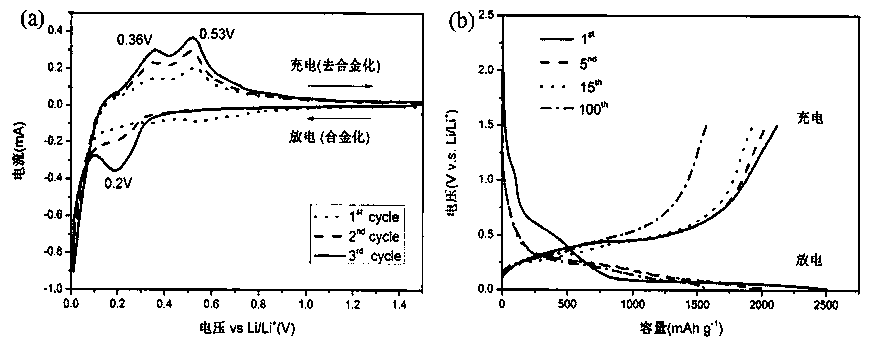

Preparation method and application of three-dimensional (3D) hierarchical porous nitrogen-doped carbon clad silicon composite material

ActiveCN107611411ARaw materials are easy to getGood lookingCell electrodesSecondary cellsMetal frameworkHigh pressure

The invention discloses a preparation method and application of a three-dimensional (3D) hierarchical porous nitrogen-doped carbon clad silicon composite material. The method comprises the following steps of mixing an organic metal framework with nano silicon and polyacrylonitrile by utilizing a high-pressure sputtering method, roasting and carbonizing at high temperature in a protective atmosphere, then removing a metal oxide in the organic metal framework by using hydrochloric acid, washing, and drying, so that the 3D hierarchical porous nitrogen-doped carbon clad silicon composite material(3D NPC@Si) is prepared. The method is used for providing great feasibility for the synthesis of a material for a negative electrode of a lithium-ion battery, which is controllable in component, controllable in structure, high in specific surface area and favorable in structural stability. The method is simple, easy and feasible and is low in cost; the prepared composite material has a higher specific surface area, favorable electron conductivity and better structural stability, and the composite material shows extremely good electromechanical performance in the material for the negative electrode of the lithium-ion battery and has a quite good industrial application prospect.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Method for separating and purifying nonane diacid

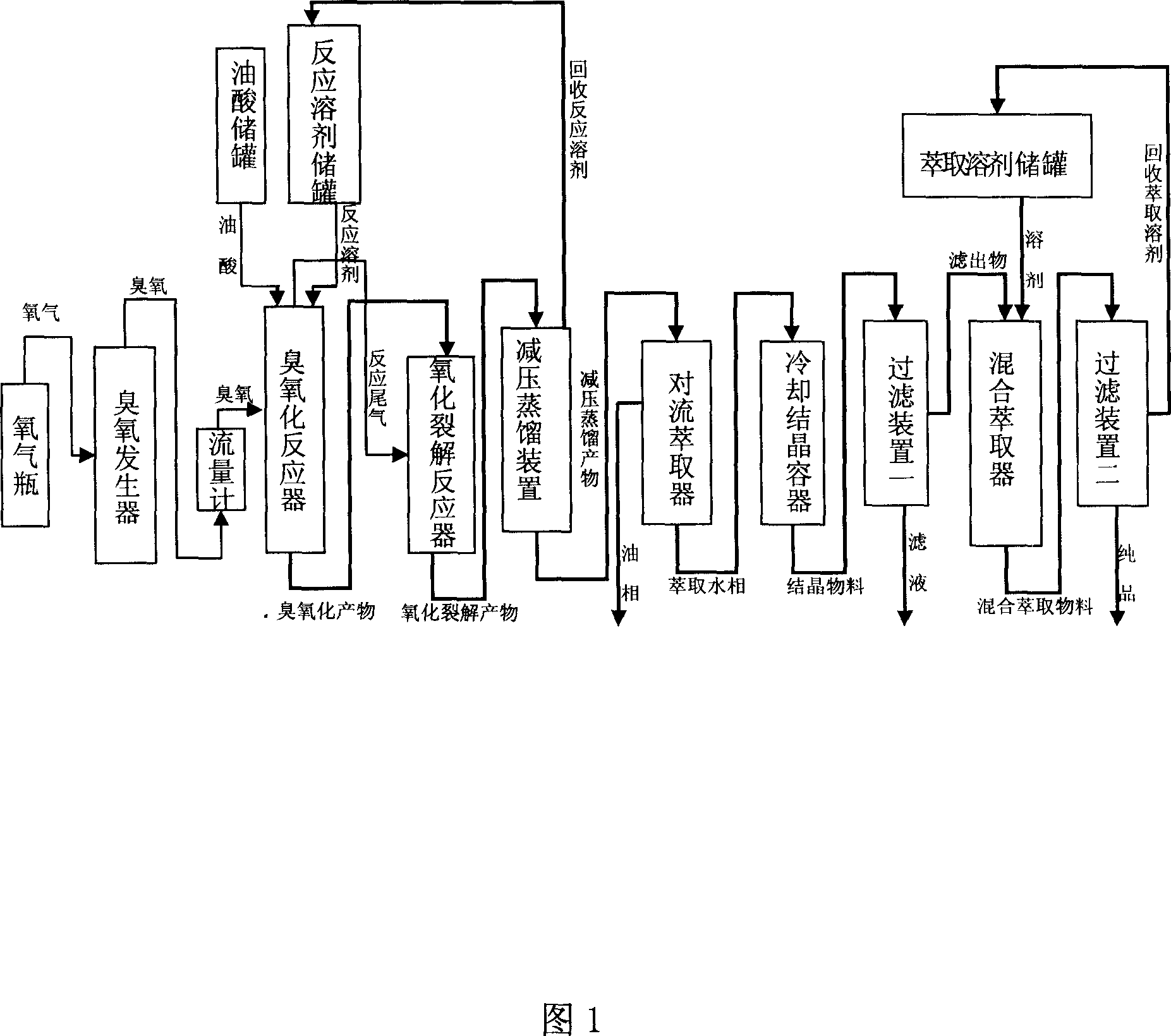

InactiveCN1970524ALow operating temperatureReduce environmental pollutionCarboxylic preparation by ozone oxidationChemical recyclingSolventChemistry

The invention discloses a separating purifying method of nonadioic acid, which comprises the following steps: oxidizing oleic acid through ozone; cracking; evaporating solvent; recycling; extracting substrate through hot water; crystallizing water phase after extracting; drying to obtain rough product of nonadioic acid; adding rough product of nonadioic acid into organic solvent; stirring; sucking; drying; obtaining the pure product of nonadioic acid. The invention removes monacid and insoluble impurity with purity of nonadioic acid over 98%, which provides clean manufacturing method.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

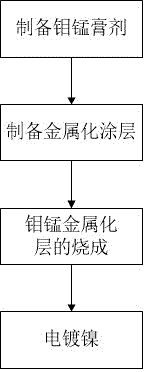

High-temperature metallization technology for yttria ceramic

InactiveCN105948826AHigh bonding strengthLower requirements than vacuum magnetron sputteringTunnel kilnSputtering

The invention discloses a high-temperature metallization technology for yttria ceramic. The active molybdenum-manganese process high-temperature metallization technology is adopted to carry out high-temperature metallization on yttria ceramic and includes the following specific steps of preparation of molybdenum-manganese paste, preparation of a metallization coating, firing of a molybdenum-manganese metallization layer, and electronickelling. In this way, according to the high-temperature metallization technology for yttria ceramic, the active molybdenum-manganese process is adopted to carry out high-temperature metallization on yttria ceramic, the production equipment requirement is lower than that of vacuum magnetron sputtering, and the equipment price is low; meanwhile, as silk screen printing coating and a continuous atmosphere protection tunnel kiln are adopted to carry out metallization, automatic production can be adopted, and large-scale continuous production can be conveniently achieved; due to the technological characteristics of the active molybdenum-manganese process, the bonding strength of a molybdenum layer formed after firing and ceramic is high.

Owner:CHANGSHU CITY YINYANG CERAMIC CO LTD

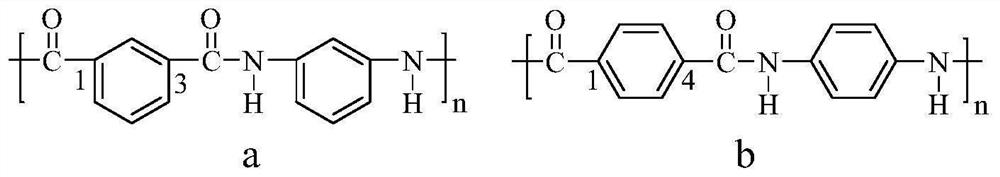

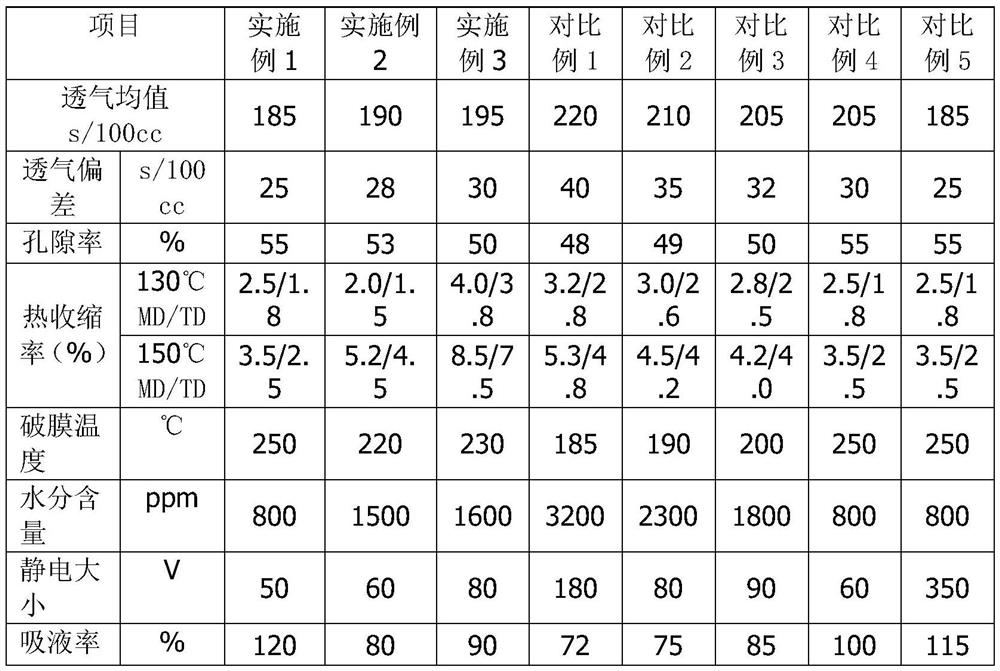

Modified composite heat-resistant lithium ion battery diaphragm and preparation method thereof

InactiveCN112216928AImprove electrochemical performanceImprove mechanical propertiesSecondary cellsNanotechnologyHeat resistanceLithium-ion battery

The invention belongs to the field of high polymer materials, and discloses a preparation method of a modified composite heat-resistant lithium ion battery diaphragm, which comprises the following steps: A, modifying aramid fibers; B, modifying an inorganic nano material; C, mixing the modified aramid fiber slurry and the modified inorganic nano slurry with a solvent in proportion to prepare organic-inorganic mixed modified slurry; and D, coating a base membrane with the organic-inorganic mixed modified slurry, and carrying out moisture solidification, washing, solvent removal and drying to obtain the modified composite heat-resistant lithium ion battery diaphragm. The problems of insufficient heat resistance, high moisture, large static electricity and the like of an existing aramid fibercoating diaphragm are solved.

Owner:长园泽晖新能源材料研究院(珠海)有限公司

Method for preparing low-pour-point lubricant additive from low-priced cotton seed oil

InactiveCN102978011AChange structureEasy to useFatty acid esterificationAdditivesDistillationCalcium formate

The invention discloses a method for preparing a low-pour-point lubricant additive from low-priced cotton seed oil. The method comprises the following steps: mixing cotton seed oil, methanol and potassium hydroxide so as to prepare fatty acid methyl esters, uniformly mixing the fatty acid methyl esters, formic acid and petroleum ethers at room temperature, stirring and heating the obtained mixture, dripping a mixture of hydrogen peroxide and phosphoric acid into the obtained mixture, standing the obtained product to carry out delamination, separating a water layer, washing an oil layer by using water until the oil layer is neutral, and carrying out reduced pressure distillation to obtain colorless transparent oily epoxidized fatty acid methyl esters, wherein the epoxy value is greater than 4-7, the iodine value is less than 2-0, the acid value is less than 1, and the yield is 90-94%; adding calcium carbonate into a residual formic acid solution after reaction so as to obtain calcium formate which can be recycled; and carrying out esterification reaction on the epoxidized fatty acid methyl esters so as to obtain epoxidized fatty acid methyl ester mixed fatty acid esters. According to the method disclosed by the invention, atalyst application amount is low, the process is clean, the implementation conditions are simple, and the mass production can be implemented conveniently.

Owner:深圳市四方精细化工有限公司

Synthetic method for epoxy soybean oil acrylate

The invention relates to a synthetic method for epoxy soybean oil acrylate. The synthetic method comprises the following steps of: uniformly mixing the soybean soil, formic acid and solvent at the room temperature, dropping the mixture of hydrogen peroxide and catalyst, stewing and layering the mixture, separating the water layer, using water to wash the oil layer to neutral and decompressing and distilling to obtain the epoxy soybean oil, wherein the epoxy value is higher than 5-8, the acid value is lower than 1, and the yield is 90-95%; adding calcium carbonate or calcium oxide to the remaining formic acid aqueous solution after reaction to obtain and recycle calcium formate; and carrying out an esterification reaction on the epoxy soybean oil to obtain the epoxy soybean oil acrylate, wherein the acid value of the epoxy soybean oil acrylate is lower than 0.5-2, the iodine value of the epoxy soybean oil acrylate is 30-45, and the viscosity of the epoxy soybean oil acrylate is 10000-20000 at 25 DEG C. The synthetic method provided by the invention is clean, safe to carry out, simple to operate, can realize effective utilization of low-concentration hydrogen peroxide, and is convenient to carry out large-scale production.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

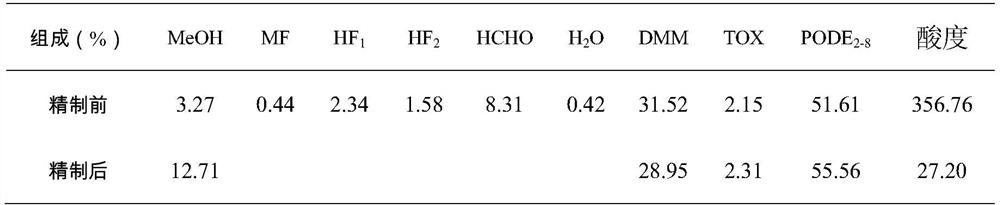

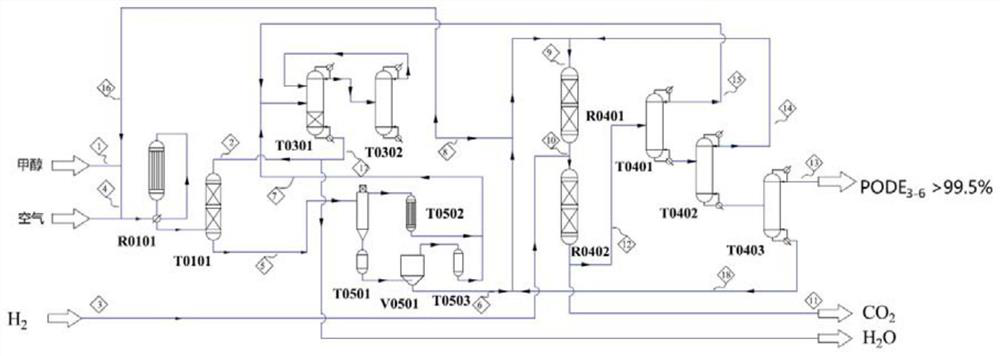

Refining process of polyoxymethylene dimethyl ether condensation product

ActiveCN111689840AReduce consumptionHigh activityOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystHydrolysis

The invention discloses a refining process of a polyoxymethylene dimethyl ether condensation product. The process includes: carrying out hydrolysis reaction on water, formaldehyde and formic acid in acondensation equilibrium product under the action of a catalyst, enabling the produced active hydrogen to reduce unhydrolyzed formaldehyde and methyl formate into methanol under the action of the catalyst, thus reaching the multi-effect refining purpose of aldehyde removal, deacidification, degreasing and dehydration of a condensation equilibrium product, and sending the refined product to a subsequent separation unit. According to the invention, the chemical characteristics of a small amount of water, formaldehyde, formic acid and methyl formate in the condensation equilibrium product are skillfully utilized, a hydrolysis reduction reaction network is formed under the action of a catalyst, formaldehyde, formic acid, methyl formate and water in the condensation equilibrium product react with one another to generate methanol which is easy to separate, and the catalytic refining process achieves multi-effect refining of aldehyde removal, deacidification and dehydration on a polyoxymethylene dimethyl ether condensation product.

Owner:DONGFANG HONGSHENG NEW ENERGY APPL TECH RES INST +1

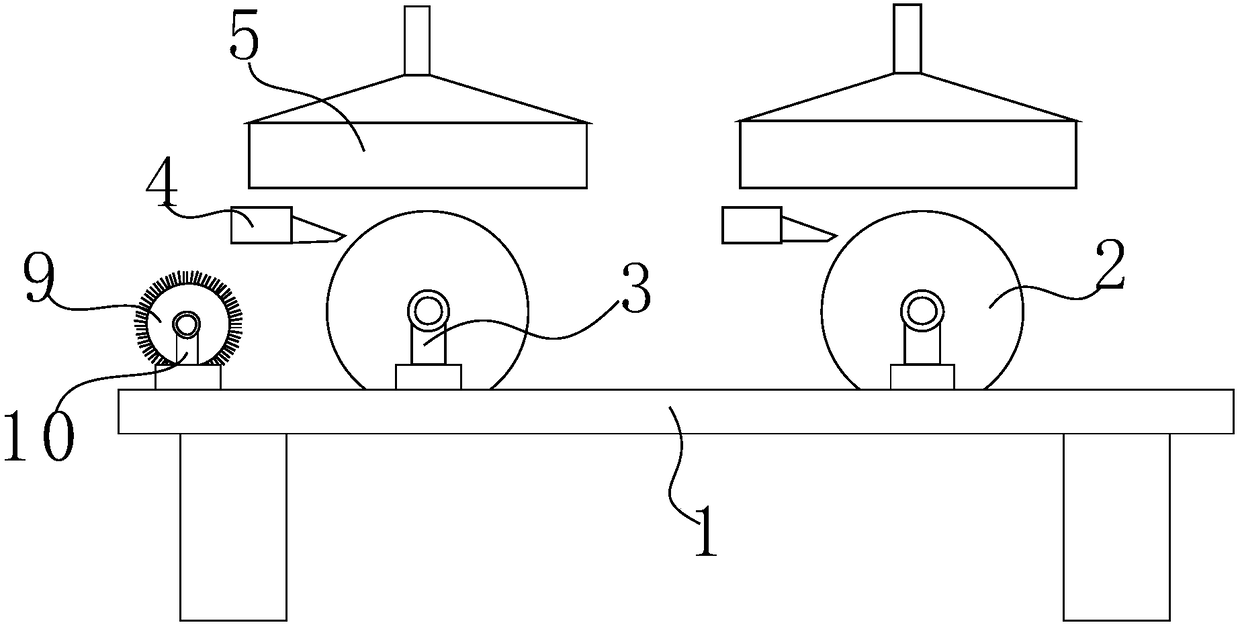

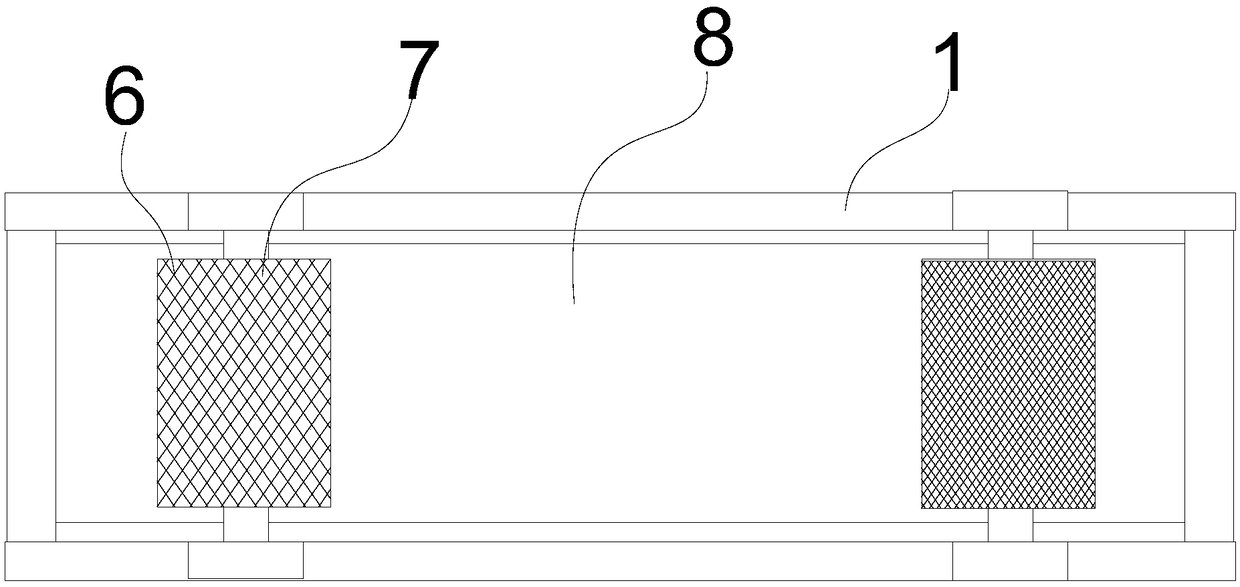

Abrasive wheel type polishing system for floorboards

PendingCN109202578ALong-term useLabor savingPlane surface grinding machinesGrinding/polishing safety devicesEngineeringGrinding wheel

The invention relates to the field of floorboard production and particularly relates to an abrasive wheel type polishing system for floorboards. The abrasive wheel type polishing system comprises a rack, abrasive wheels arranged on the upper portion of the rack, cooling mechanisms and dust removing mechanisms, wherein the cooling mechanisms and the dust removing mechanisms are arranged above the abrasive wheels. According to the polishing systems, the surfaces of the abrasive wheels are electroplated with diamond, and discharging nicks are arranged in cooperation so that the abrasive wheels can be used for a long term, the operation of replacing abrasive paper repeatedly can be omitted, and manpower can be saved; meanwhile, the cooling mechanisms and the dust removing mechanisms are arranged in cooperation, so that long-time mass continuous production is facilitated, and production efficiency is ensured.

Owner:常州市岚钨合金有限公司

Preparation method of L-pyroglutamic acid

ActiveCN107043343ANo emissionsSimple production processOrganic chemistry methodsActivated carbonL-Pyroglutamic Acid

The invention discloses a preparation method of L-pyroglutamic acid. The method comprises the following steps: (1) adding glutamic acid or hydrolyzed recovery material into a reaction kettle and then heating, controlling the temperature to be 145-150 DEG C, carrying out intermittent mixing, and enabling the mixture to be completely dissolved so as to obtain feed liquid; adding purified water into the feed liquid, crystallizing for a plurality of times and centrifuging, merging crystallized products to obtain solid A, and merging mother liquor to obtain liquid 1; (2) heating the solid A up to 35-45 DEG C in a solvent, enabling the solid A to be completely dissolved and then sending the dissolved product to a bleaching tank, heating up to 65-75 DEG C, then adding activated carbon, absorbing under the condition of heat preservation, and filtering to obtain a decolored solution; carrying out cooling crystallization on the decolored solution and then centrifuging to obtain a wet product; recycling crystallization mother liquor for a plurality of times, concentrating and recrystallizing to obtain solid B and liquid 2; (3) carrying out vacuum drying on the wet product at the temperature of 80-85 DEG C; after drying is finished, cooling, and detecting to obtain the L-pyroglutamic acid. The method is simple in production technology, mild in reaction conditions, high in product yield and purity, free from emission of pollutants and wastes, and convenient for large-scale continuous production.

Owner:峨眉山市龙腾生物科技有限公司

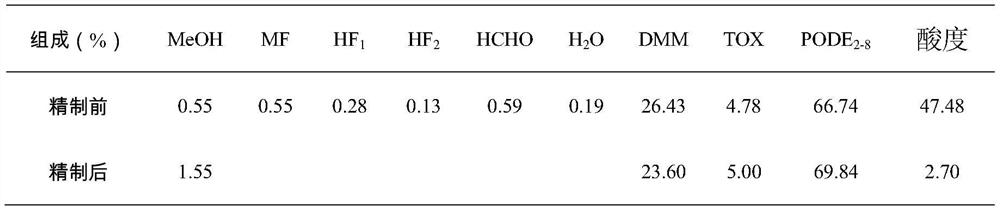

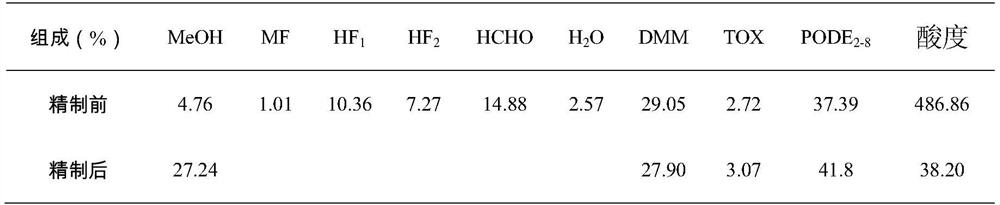

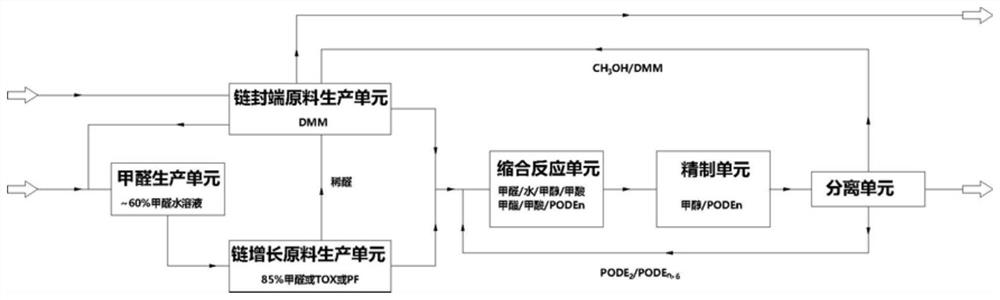

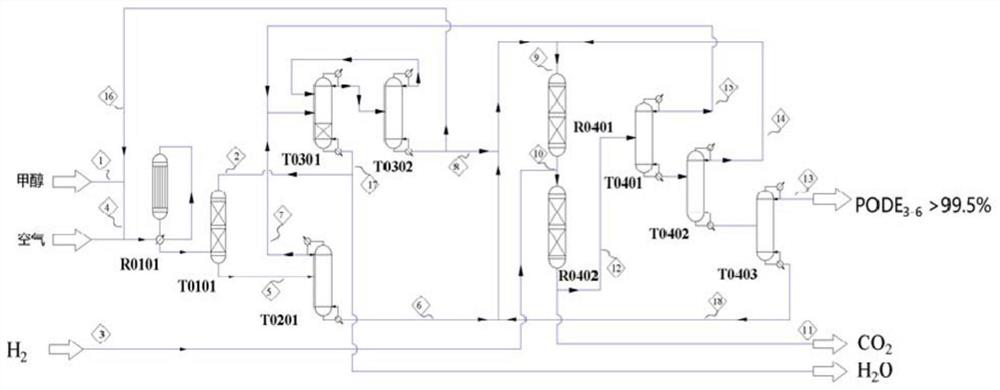

Preparation process for preparing polyoxymethylene dimethyl ether by taking methanol as raw material

PendingCN111978161ASolving the Recycling DilemmaImprove utilization efficiencyOrganic chemistryOrganic compound preparationPolymer scienceCatalytic oxidation

The invention relates to a preparation process for preparing polyoxymethylene dimethyl ether (PODE) by using methanol as a raw material, which comprises the following steps: by using methanol and methylal as raw materials, carrying out catalytic oxidation to prepare concentrated formaldehyde with the concentration of 50% or above; dehydrating the concentrated formaldehyde to prepare a chain extension raw material; preparing a chain-terminated raw material methylal with the water content of less than 0.5% through reactive distillation by taking a chain extension raw material byproduct dilute aldehyde and a light-boiling circulating material flow of a separation unit as raw materials; after the chain extension raw material and the chain-terminated raw material are subjected to a condensationreaction, converting formaldehyde, water, formic acid and methyl formate of a condensation product polyoxymethylene dimethyl ether crude product into methanol through catalytic refining by one-step multi-effect refining; and separating the refined product to obtain PODE<3-6>. By adopting the preparation process, the utilization rate of methanol and dilute aldehyde can be effectively improved, multi-element azeotropic impurities are removed, the product quality is improved, and the stability of a device is improved.

Owner:CHENGDU ZHONGKE CATALYSIS TECH CO LTD +1

Method for modifying lubricating oil additive by using thioacetic acid

The invention relates to a method for modifying a lubricating oil additive by using thioacetic acid. The mixed fatty acid ester of epoxy polyisobutylene is functionally modified to obtain the extreme pressure anti-wear and anti-oxidative lubricating oil additive by using the thioacetic acid, wherein the pour point is lowered from -2 to -5 DEG C before modification to -10 to -20 DEG C after modification. A process is clean, the method is safe in implementation and convenient to operate, and large-scale production is facilitated.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

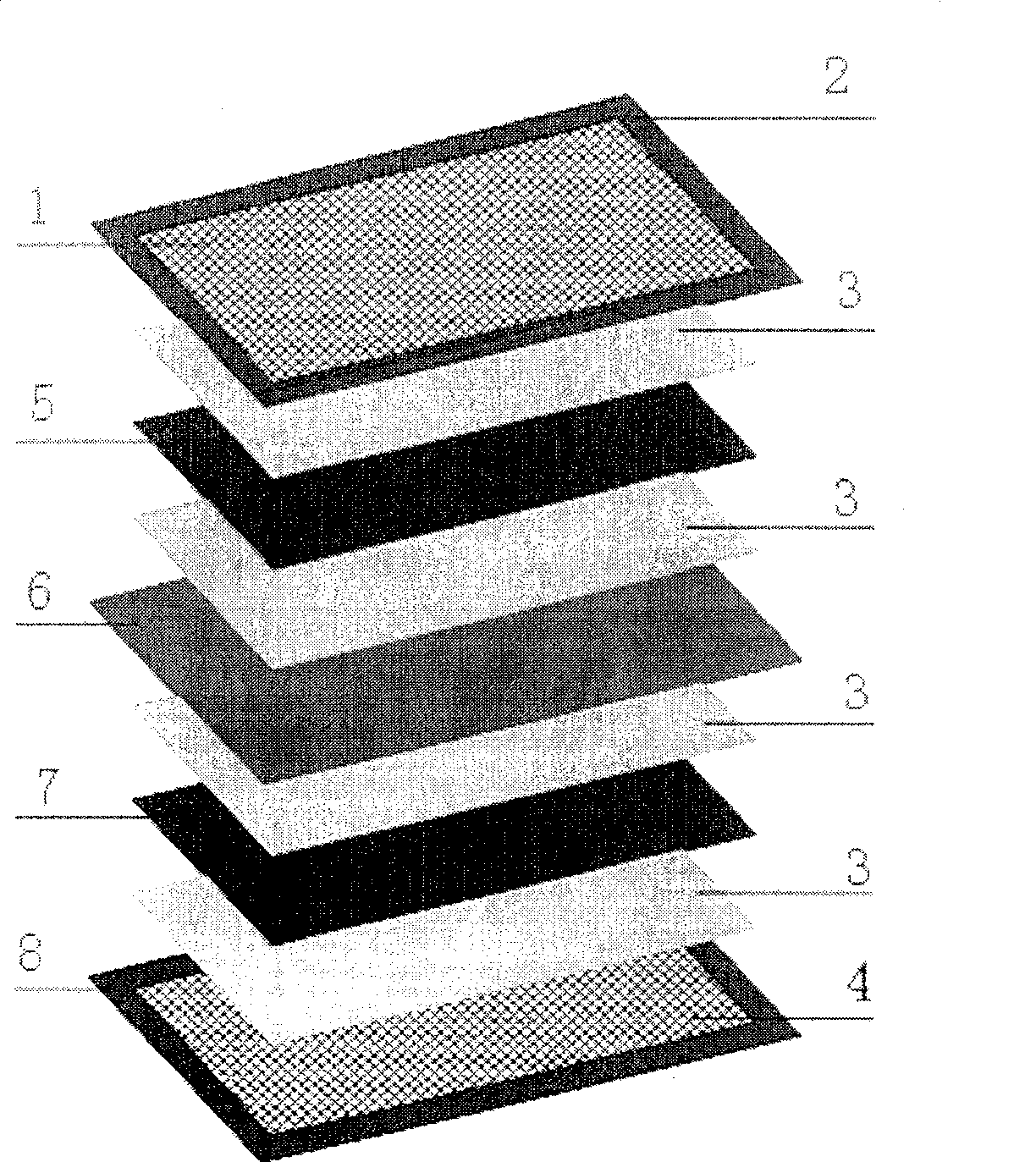

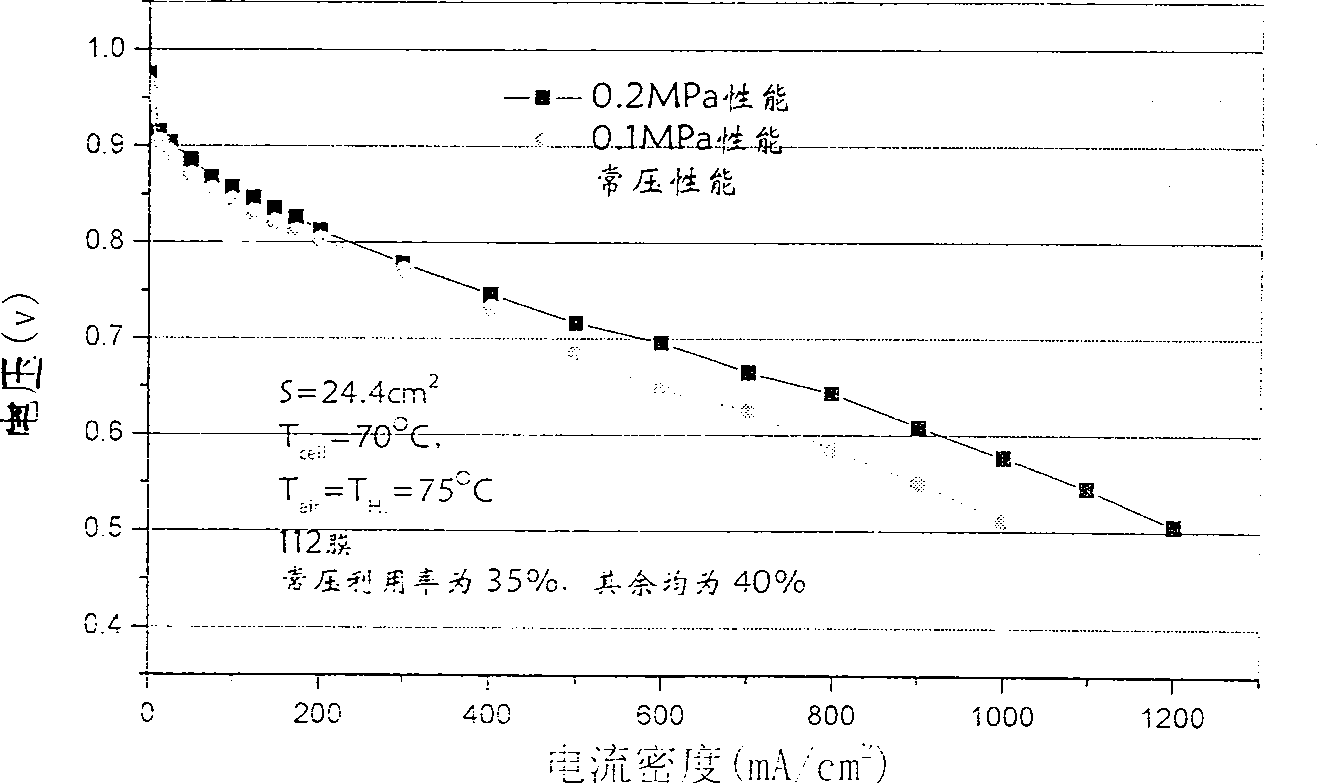

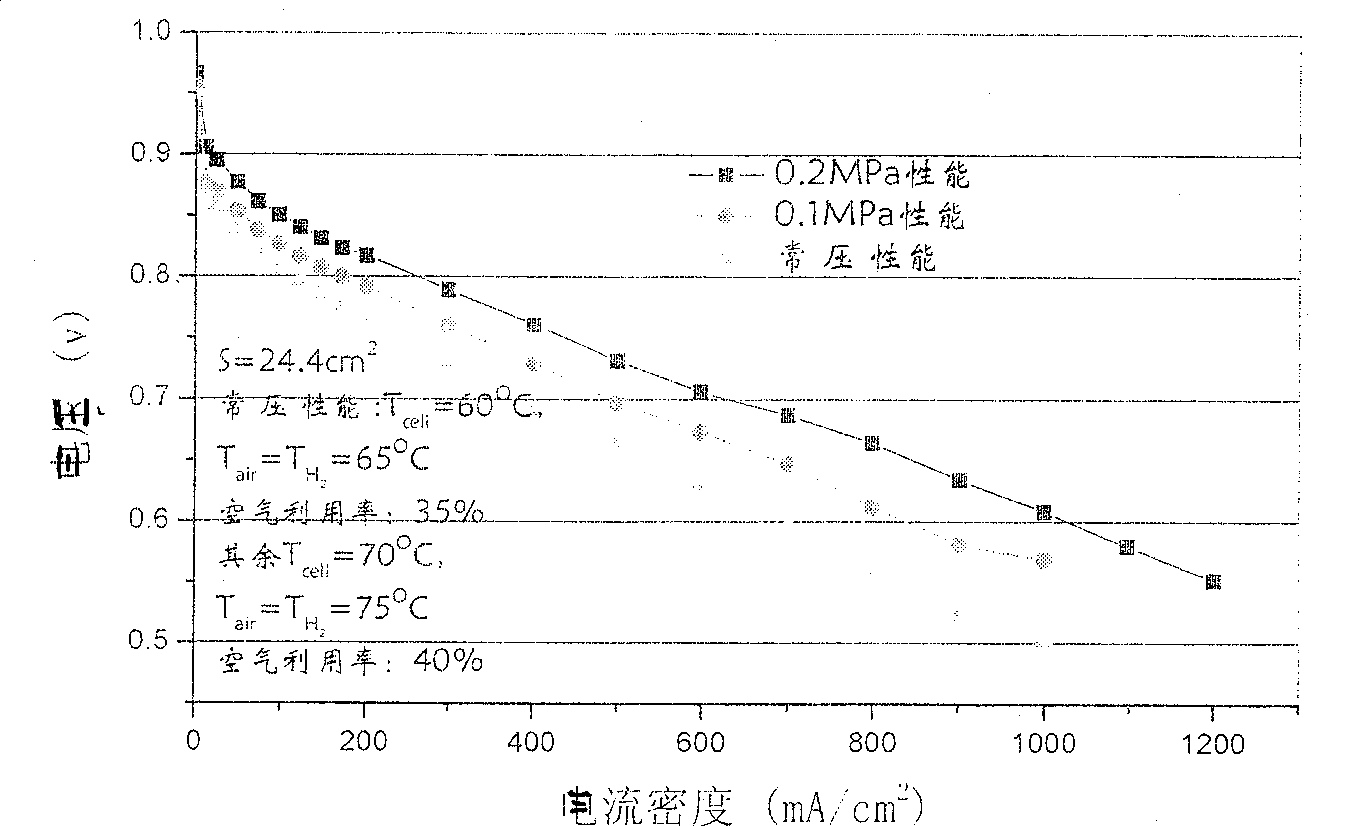

Production method of membrane electrode of proton-exchange membrane fuel battery

ActiveCN100486006CEasy to manufactureImprove performanceFinal product manufactureCell electrodesProtonEngineering

Owner:SUNRISE POWER CO LTD

Metal carrier loaded copper-based SCR catalyst and preparation method thereof

PendingCN113198529AEvenly distributedIncrease coating volumeNitrous oxide captureGas treatmentRare-earth elementMolecular sieve

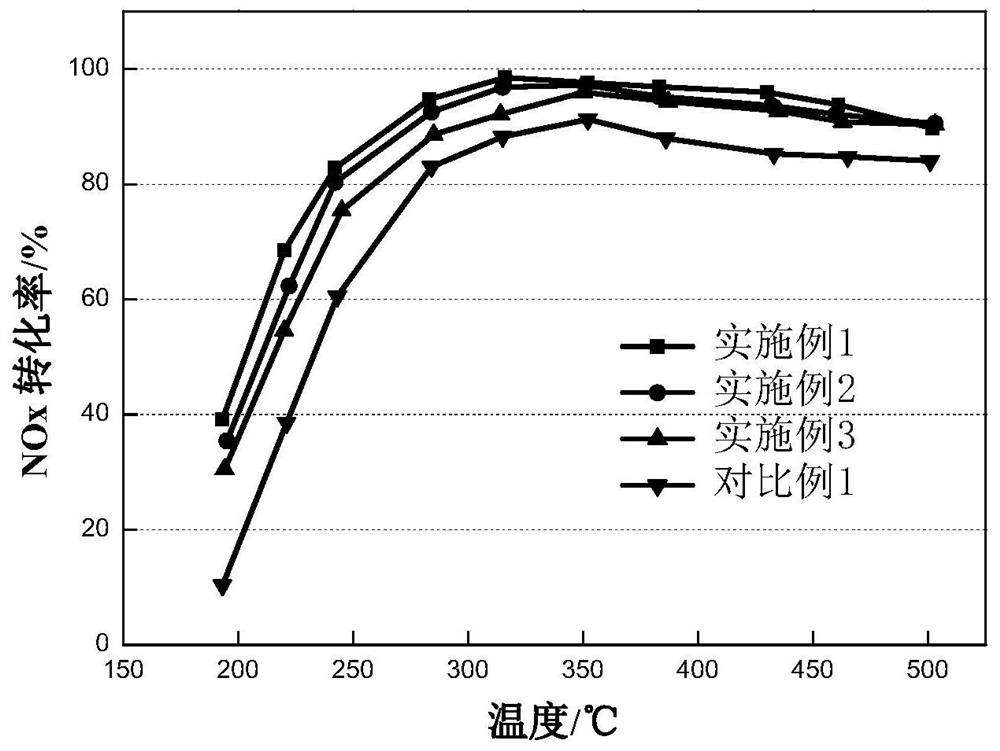

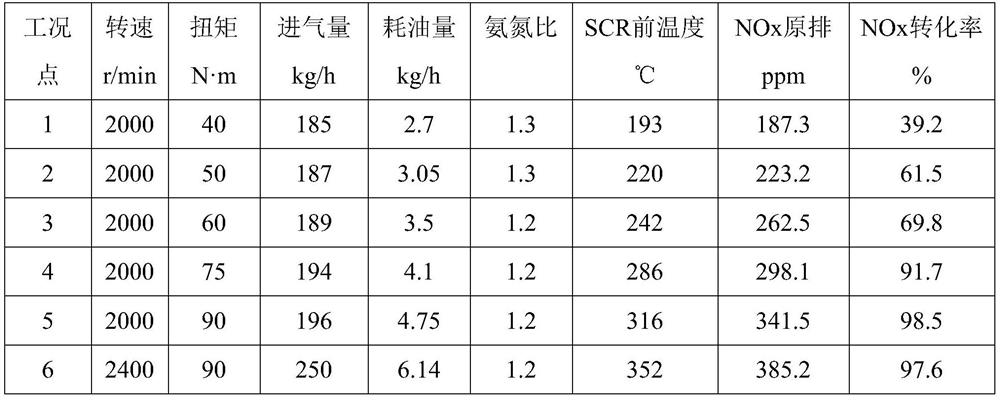

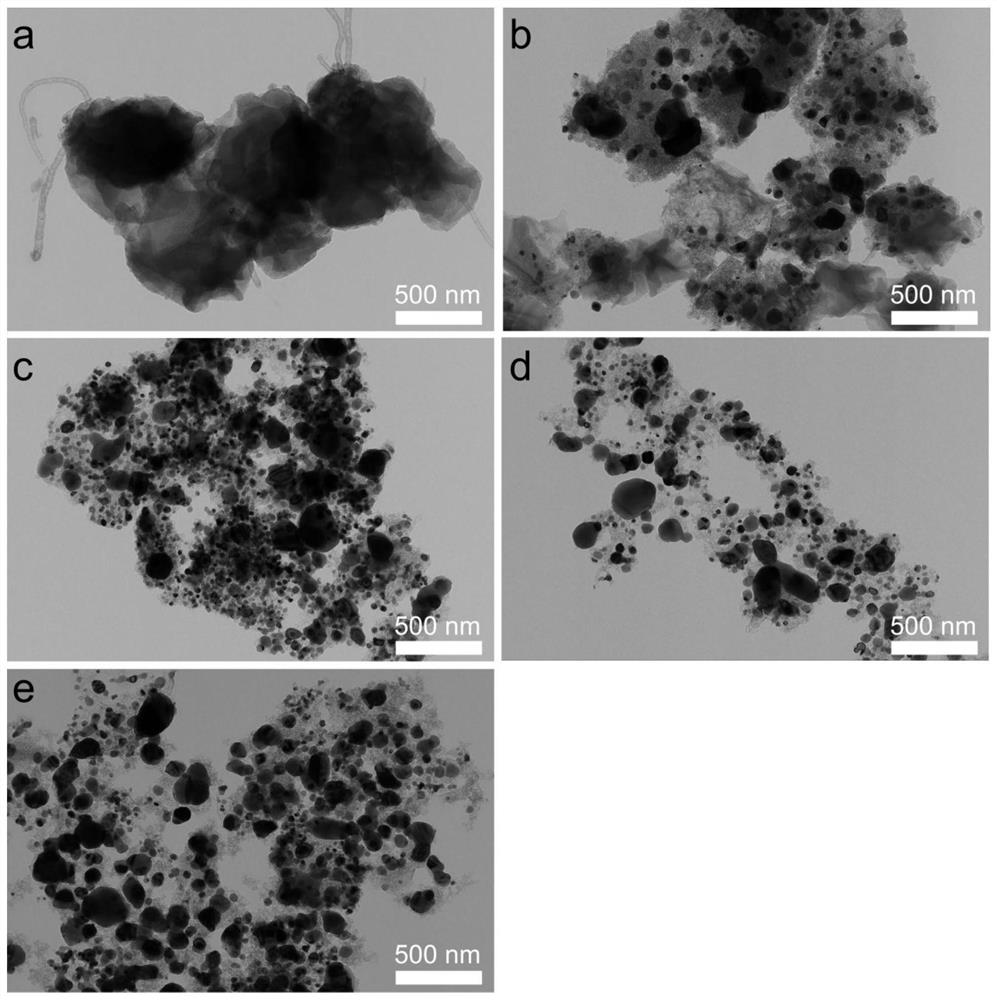

The invention belongs to the technical field of SCR denitration, and particularly relates to a metal carrier loaded copper-based SCR catalyst and a preparation method thereof. The metal carrier loaded copper-based SCR catalyst comprises a carrier and a coating; the carrier is a metal carrier; the coating is a copper-containing molecular sieve; the copper-containing molecular sieve further contains rare earth elements; and the content of the rare earth elements accounts for 0.1%-5% of the weight of the molecular sieve. The preparation process of the catalyst specifically comprises the steps of metal carrier pretreatment, molecular sieve slurry preparation, slurry applying and catalyst roasting. The Cu-SCR catalyst prepared through the method is uniform in coating distribution, the coating amount of the coating is high and can reach 160 g / L, the bonding firmness of the coating and the carrier is high, the coating falling rate is smaller than 1%, the production technological process is simple, large-scale continuous production is facilitated, and a bench test shows that the highest conversion rate of NOx at the temperature of 200-500 DEG C can reach 98.5%.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

Technique for producing ferrous sulfate monohydrate by push plate kiln

The present invention relates to technology of producing ferrous sulfate monohydrate in a push plate kiln. Depurated green vitriol as the material carried on the push plate is made to pass slowly through the roasting cavity inside the push plate kiln so as to be preheated, high temperature roasted and cooled successively to produce ferrous sulfate monohydrate. The present invention has the advantages of simple operation, reliable running, stable product quality, low power consumption, no environmental pollution, easy control and suitability for continuous industrial production.

Owner:乐昌市银星化工有限公司

Preparation method and application of carbon-loaded nickel catalyst

ActiveCN113042054AEvenly dispersedContent adjustableCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNickel catalystPtru catalyst

The invention discloses a preparation method of a carbon-loaded nickel catalyst. The preparation method comprises the following steps: 1) depositing a certain amount of metal salt on the surface of a carbon carrier or a precursor; and 2) roasting the carbon carrier or the precursor deposited with the metal salt in step 1) in an inert protective atmosphere for a certain time to obtain the carbon-loaded nickel catalyst. The method is simple and easy to implement and low in cost, shows excellent catalytic performance in a reaction for preparing hydrogen peroxide through electrochemical oxygen reduction, and has a very good industrial application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

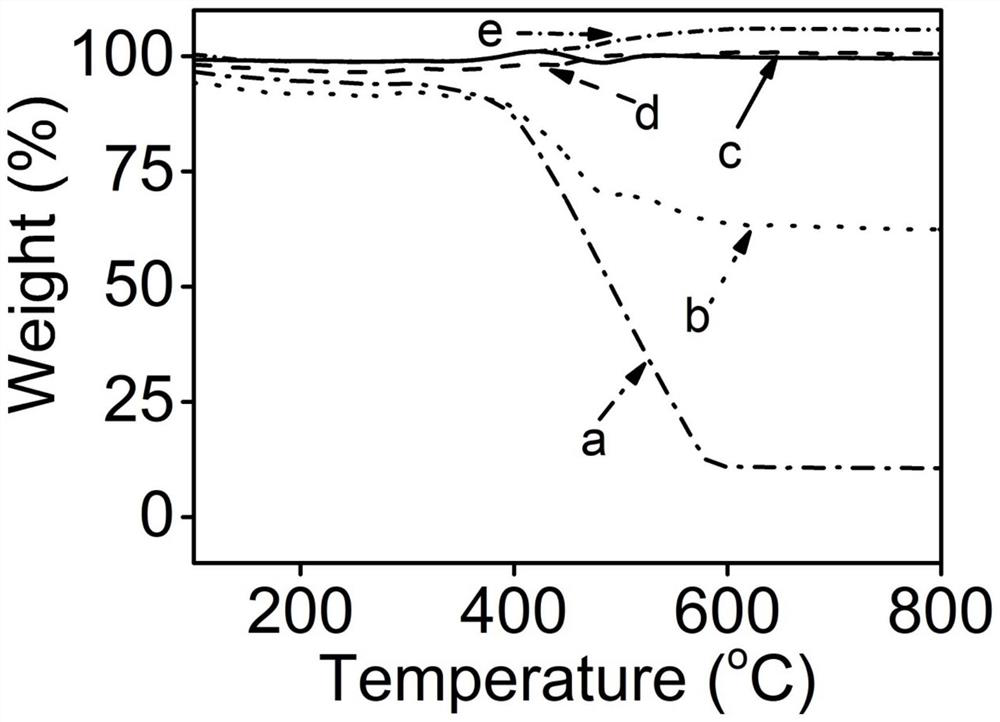

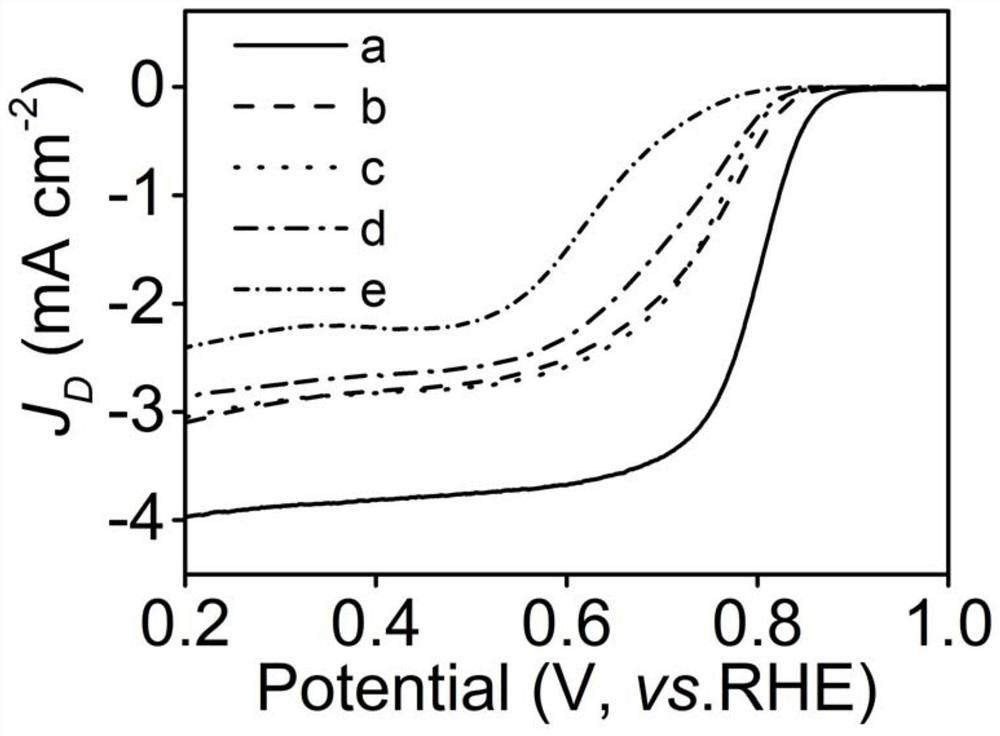

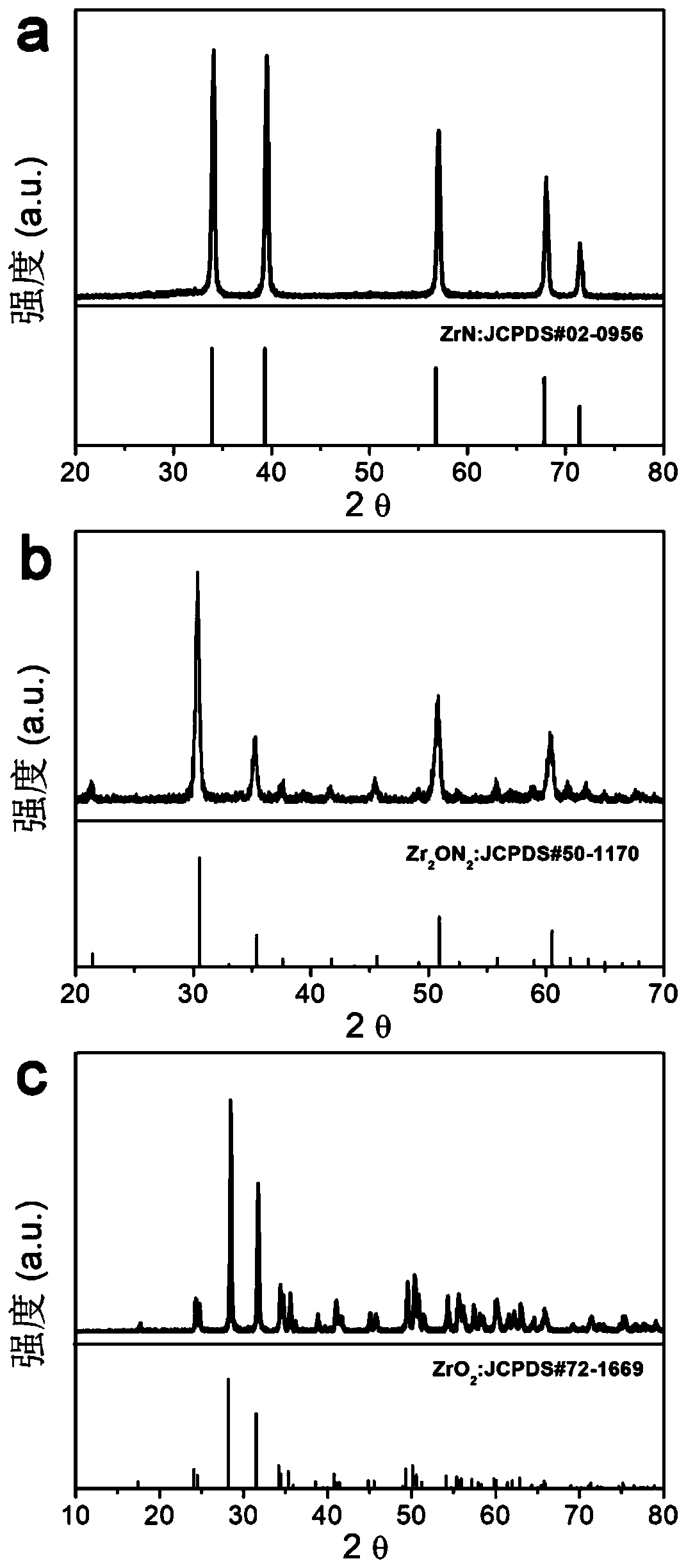

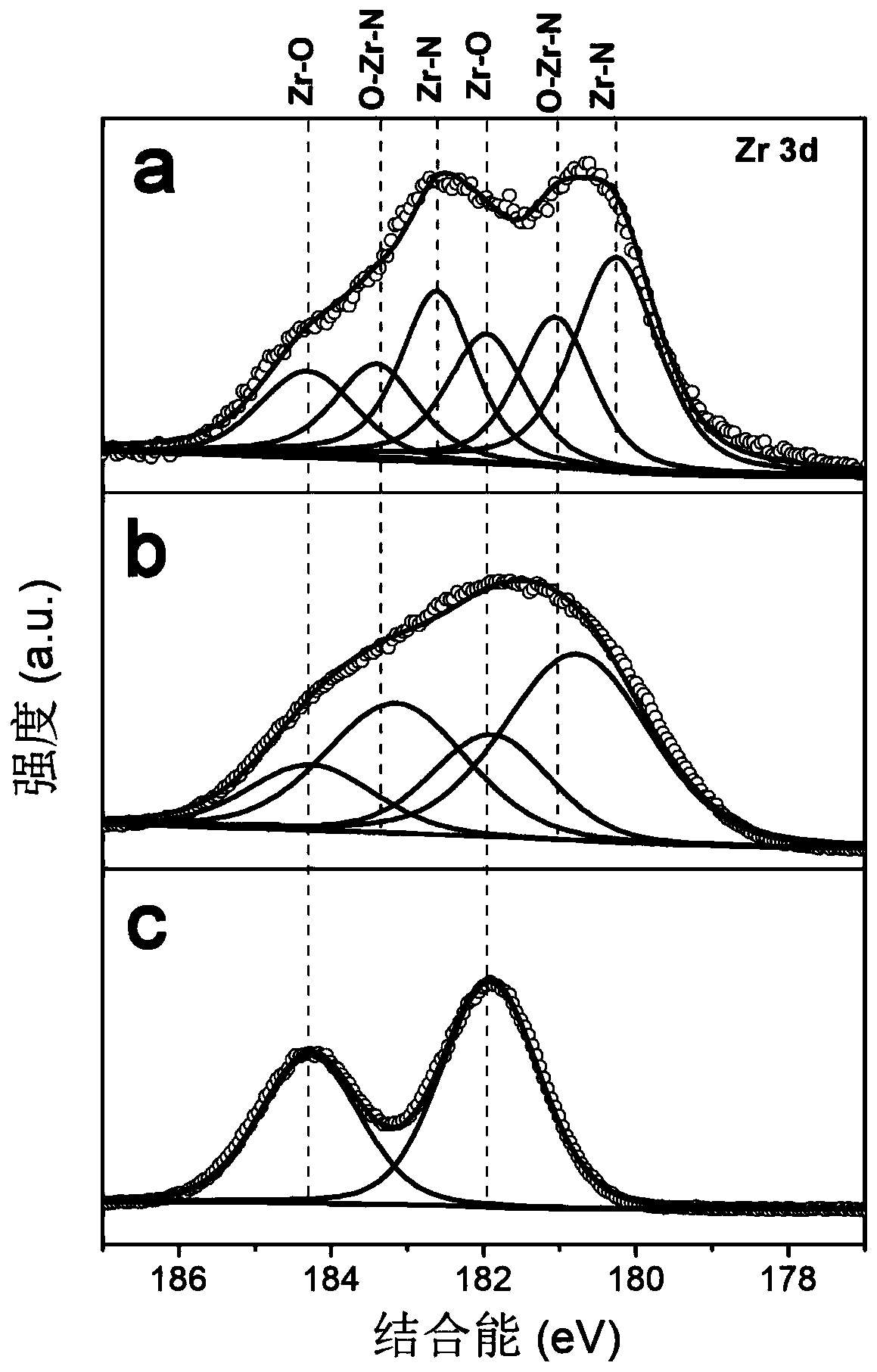

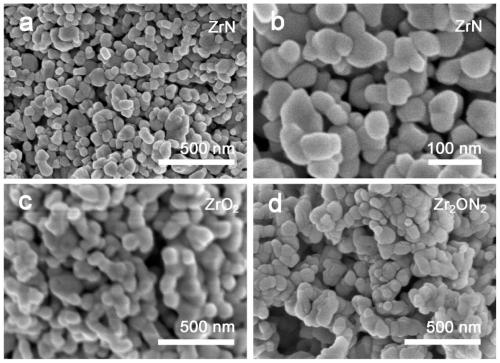

Oxygen reduction electrocatalyst material and preparation method thereof

InactiveCN111490260AImprove catalytic performanceRich reservesMaterial nanotechnologyCell electrodesCathode catalystPrecious metal

The invention discloses an oxygen reduction electrocatalyst material and a preparation method thereof. The catalytic active component of the catalyst is one or more of ZrN, a ZrN composite material and a ZrN doped material; anhydrous zirconium chloride is used as a metal source, and dissolved in an absolute ethyl alcohol solution; then, a certain amount of urea is added, and after uniformly mixing, a colloidal precursor is obtained; and the obtained precursor is placed in a protective atmosphere for high-temperature roasting and nitriding, and a pure-phase zirconium nitride nanoparticle catalyst is obtained. The applicant finds that zirconium nitride, especially a cubic phase zirconium nitride material, has excellent oxygen reduction electrocatalytic performance, can replace precious metalPt in a fuel cell to serve as a cathode catalyst, and has the characteristics of low cost, high activity and high stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A method for modifying lubricating oil additive with trimethyl borate

The invention relates to a method for modifying lubricating oil additives with trimethyl borate. In the method, epoxy polyisobutylene and trimethyl borate are evenly mixed, heated up to the reaction temperature under stirring, and unreacted is evaporated under reduced pressure after the reaction. Trimethyl borate is a lubricating oil additive for obtaining light yellow transparent oily boron-containing epoxy polyisobutylene. The lubricating oil additive of boron-containing epoxy polyisobutylene obtained by the method of the present invention has an acid value of less than 0.05-0.5, a viscosity of 6000-9000 at a temperature of 40°C, a viscosity of 210-320 at a temperature of 100°C, and a viscosity index of 135. ‑175, flash point 200‑230, pour point ‑15~‑22. The invention has a clean process, is environmentally friendly, does not require high-pressure and high-temperature devices, has simple implementation conditions, is convenient for large-scale continuous production, is beneficial to the reuse of resources, increases the added value of products, and reduces environmental pollution. The lubricant base oil has good compatibility, which opens up a new way for the production of new lubricant additives.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Method for modifying lubricating oil additive by using thioacetic acid

The invention relates to a method for modifying a lubricating oil additive by using thioacetic acid. The mixed fatty acid ester of epoxy polyisobutylene is functionally modified to obtain the extreme pressure anti-wear and anti-oxidative lubricating oil additive by using the thioacetic acid, wherein the pour point is lowered from -2 to -5 DEG C before modification to -10 to -20 DEG C after modification. A process is clean, the method is safe in implementation and convenient to operate, and large-scale production is facilitated.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

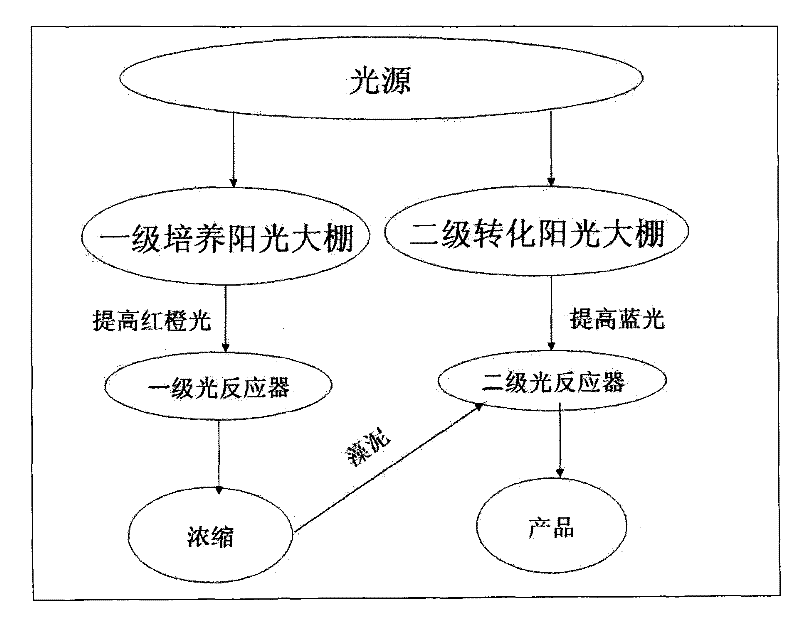

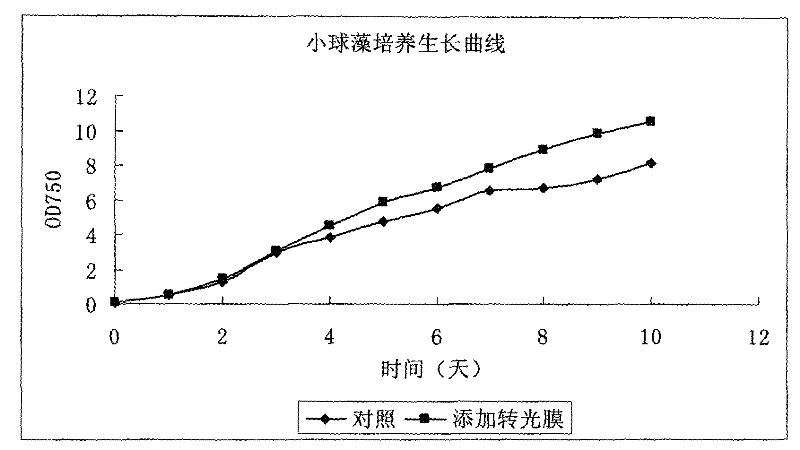

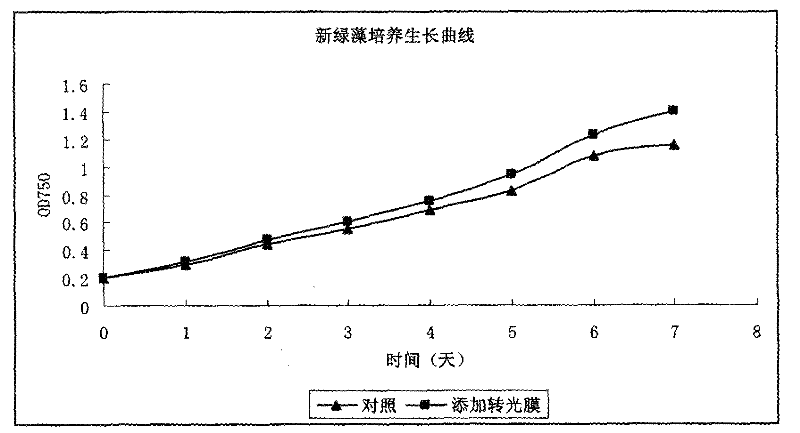

Two-step method for cultivating microalgae by using light conversion film

ActiveCN101575566BCultivate applicableMeet the needs of different wavelengths of lightUnicellular algaeMicroorganism based processesLength waveTwo step

The invention provides a two-step method for cultivating microalgae by using a light conversion film, comprising the following steps of: step one, carrying out the cultivation by using a first light conversion film so as to quickly accumulate the biomass; and step two, cultivating the microalgae obtained in the first step by using a second light conversion film, thus realizing the conversion of useful products, wherein the first light conversion film converts the light from the light source into the light with the wavelength within 400-700nm; and the second light conversion film converts the light from the light source into the light with the wavelength within 400-500nm.

Owner:ENN SCI & TECH DEV

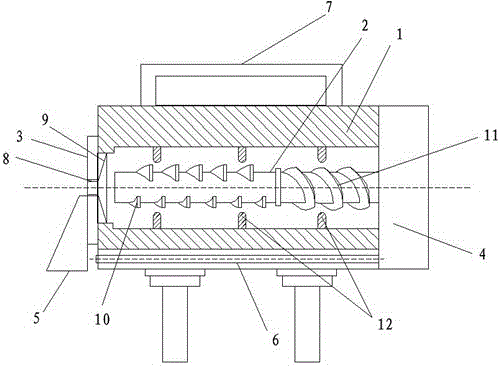

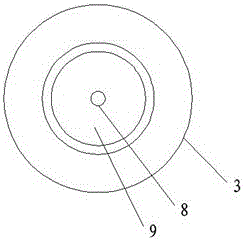

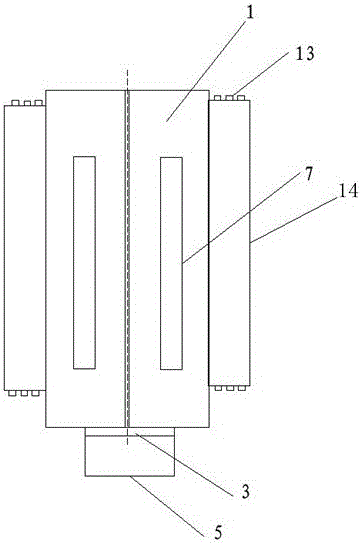

Single-screw extrusion cavity with good mixing effect

The invention discloses a single-screw extrusion cavity with a high mixing effect. The extrusion cavity comprises an extrusion rod combined by different screw threads, a seal cavity shell body, a cooling cavity shell body, an extrusion port close plate and a material guiding baffle plate; the seal cavity shell body is internally provided with a cylindrical seal cavity, and the inner side of the seal cavity shell body is provided with four groups of pin structures; the screw-thread extrusion rod is provided with two extrusion screw threads formed by combining different shapes; the outlet end of the seal cavity shell body is provided with the extrusion port close plate; the diameter of an extrusion port of the extrusion port close plate is 1.1-1.3 cm. Through shrinking the pore diameter of an extrusion port of a cavity body of a conventional commonly-used single-screw extruder, the pressure between the extrusion cavity internal screw-thread extrusion rod and mixed materials is improved, and at the same time, with cooperation of the multiple groups of pin structures inside an extrusion cavity, uniform stress between different materials at positions in the extruder seal cavity is ensured, and the mixing effect of whole powder coating raw materials is improved; and a produced product is high in density and high in glossiness, the materials are convenient to discharge by the intermittent extrusion screw threads, and large-scale continuity production of enterprises is convenient.

Owner:ZHANGJIAGANG JIANGNAN POWDER COATING

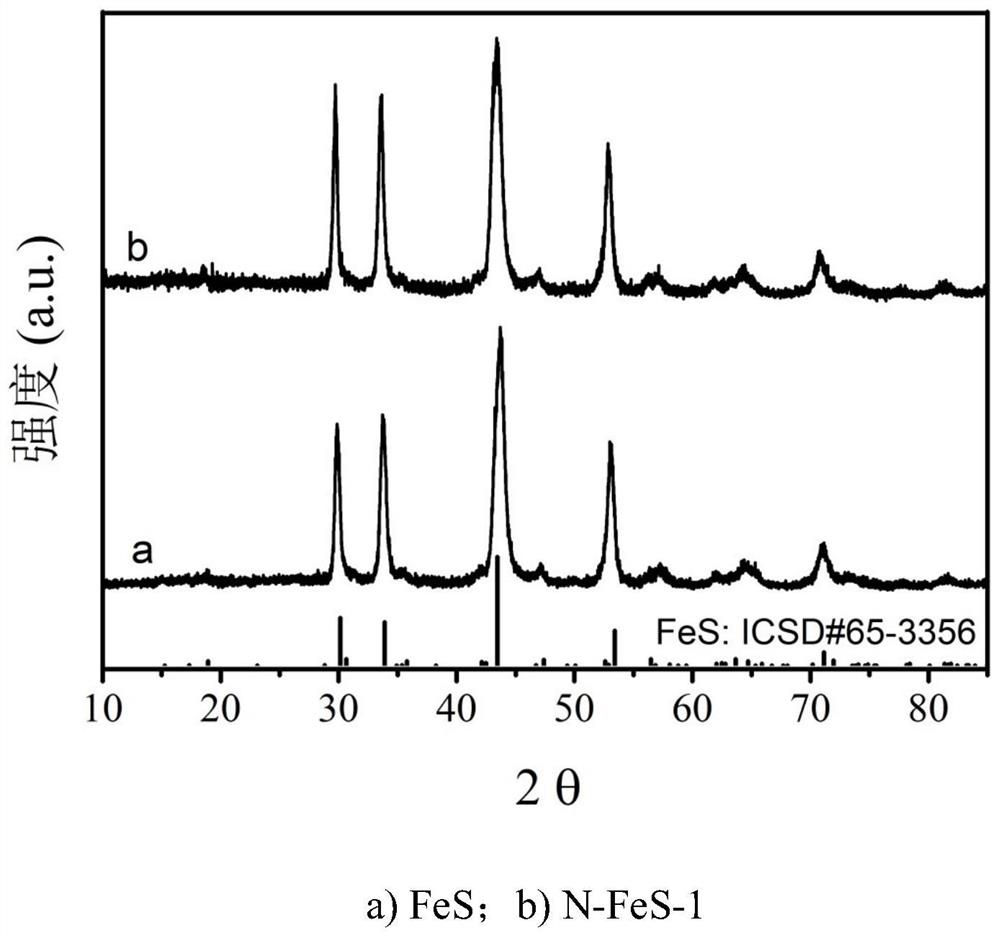

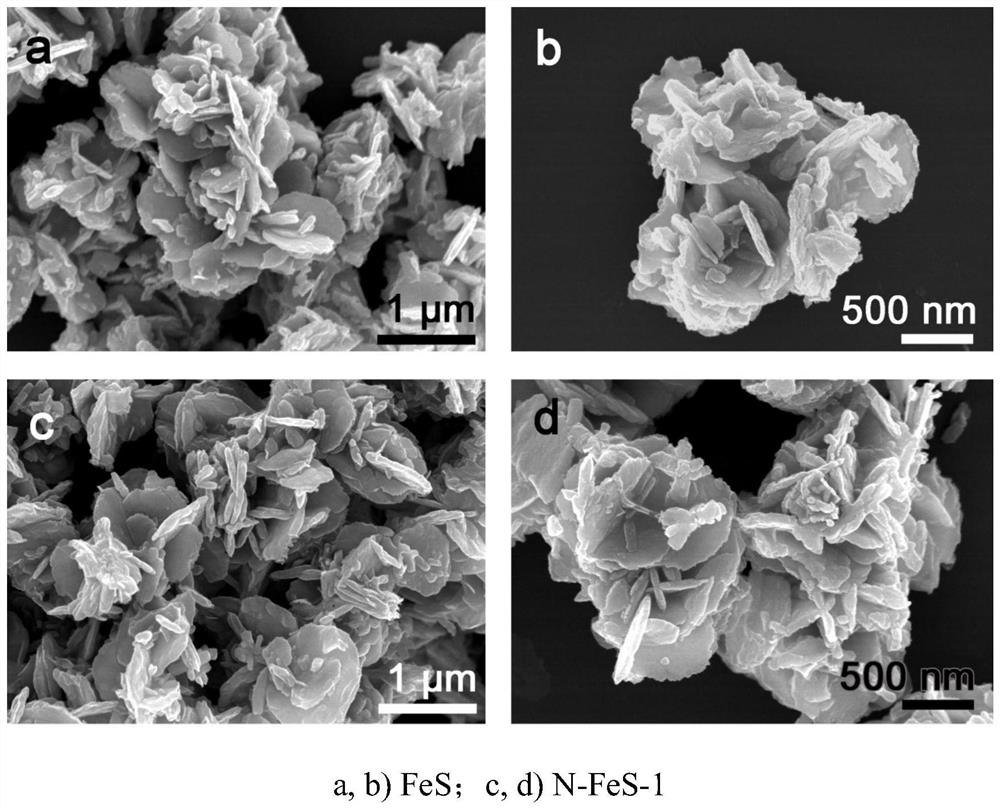

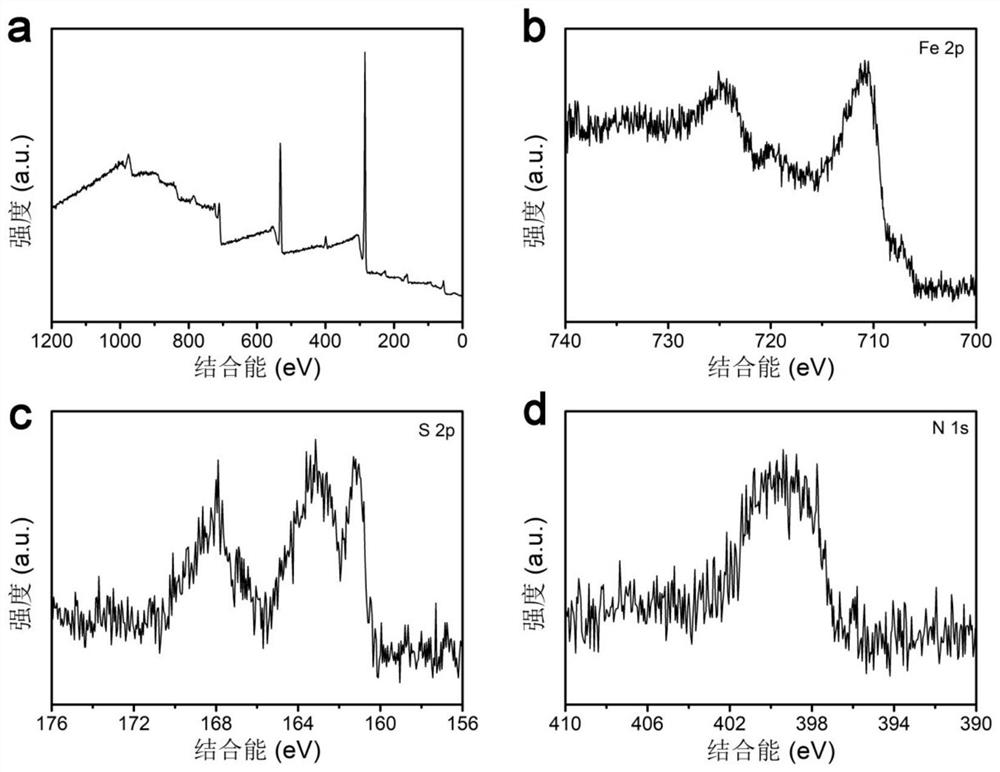

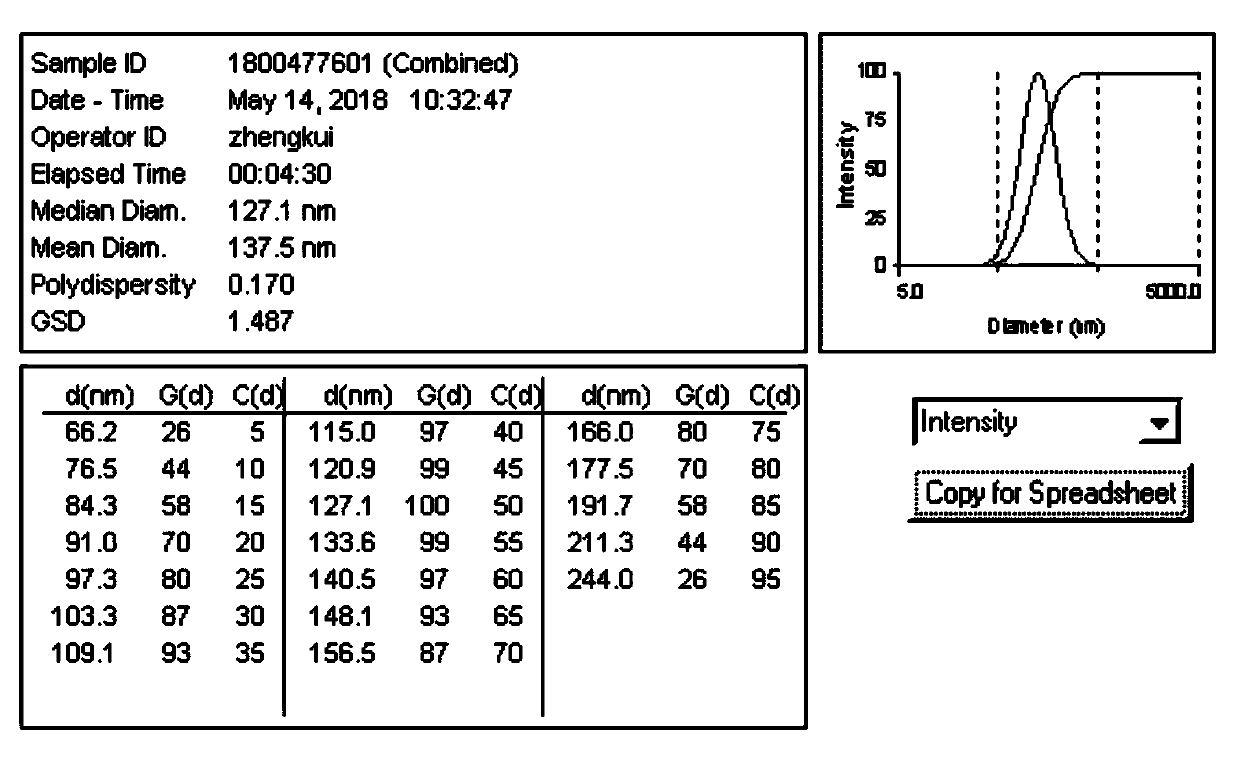

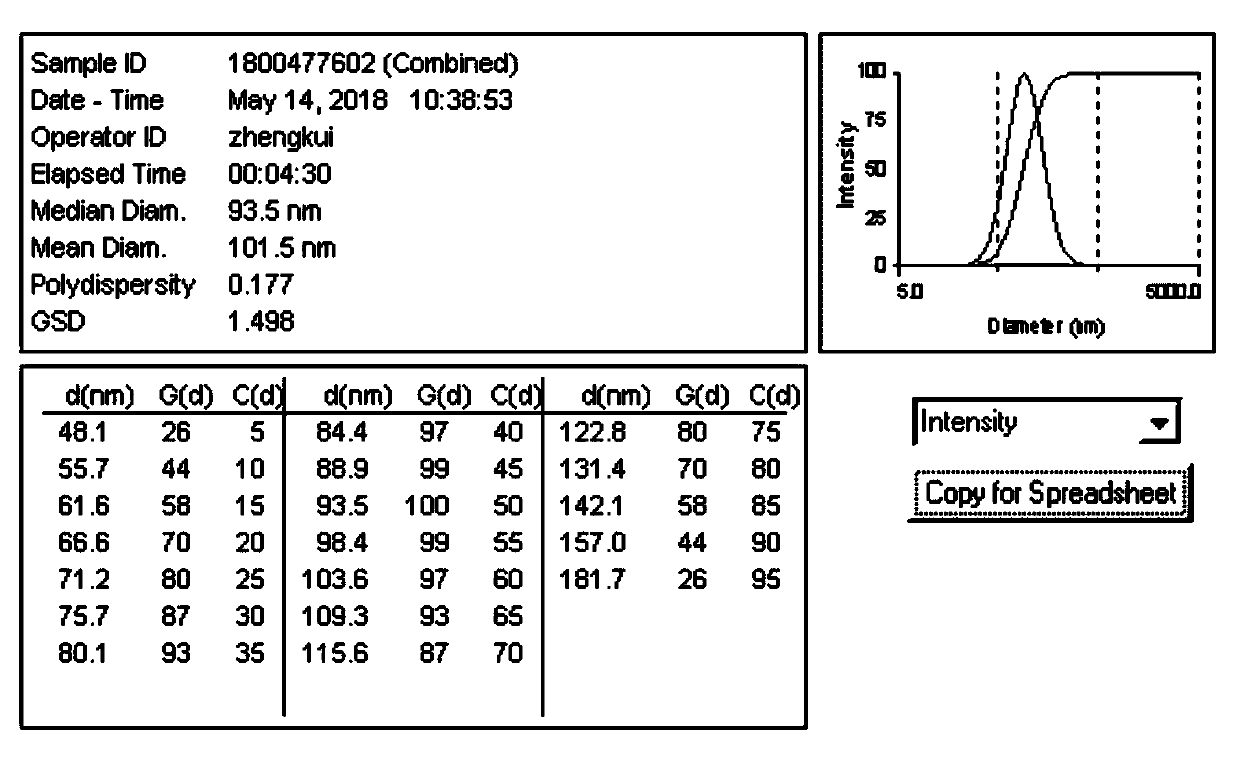

A nitrogen-doped ferrous sulfide redox catalyst material and its preparation and application

ActiveCN112421060BRich reservesLow pricePhysical/chemical process catalystsCell electrodesPtru catalystCarbamate

The invention discloses a preparation method of a nitrogen-doped ferrous sulfide (N-FeS) flower-shaped microsphere material and its electrocatalytic oxygen reduction application. In the method, diethyl dithiocarbamate is used as a sulfur source to react with ferrous chloride in an aqueous solution to obtain the precipitation of a sulfur-containing iron-based precursor. The FeS obtained after the sulfidation reaction has a stable morphology, and the flakes are combined to form flower-like microspheres with uniform sizes. The material can be used as an electrocatalyst to catalyze the oxygen reduction reaction, and has high catalytic activity and stability. This synthesis method provides a great possibility for the synthesis of oxygen-reducing electrocatalytic materials with controllable composition and structure, high specific surface area and good durability. At the same time, the synthesis method is simple and easy, the cost is low, it is suitable for large-scale production, and it shows excellent activity and stability in the electrochemical oxygen reduction reaction, and has a good industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Refining method of L-glutamic acid

InactiveCN107286033AHigh purityEmission reductionOrganic compound preparationAmino-carboxyl compound preparationActivated carbonFiltration

The invention discloses a refining method of L-glutamic acid. The method comprises the following steps of (1) adding a solvent to a bleaching tank, heating, adding aginomoto, stirring evenly, adding activated carbon when the temperature is raised to 70-80 DEG C, carrying out insulated adsorption and filtering to obtain a decolored solution; (2) carrying out precise filtration on the decolored solution obtained in the step (1), feeding the decolored solution into a neutralization tank, keeping the temperature at 70-80 DEG C, adjusting the pH to acidity, carrying out cooling crystallization and then centrifuging to obtain a wet product and a mother liquid; and (3) carrying out vacuum drying on the wet product obtained in the step (2), wherein the vacuum drying temperature is smaller than 80 DEG C; and then carrying out cooling and detecting to obtain the L-glutamic acid. The refining method is simple in production technology and low in equipment requirement, free of high-temperature and high-pressure requirements, mild in reaction condition, high in product yield and purity, low in emission of the mother liquid, the highest temperature in the production process is 70-80 DEG C, and large-scale continuous production is convenient to implement.

Owner:峨眉山市龙腾生物科技有限公司

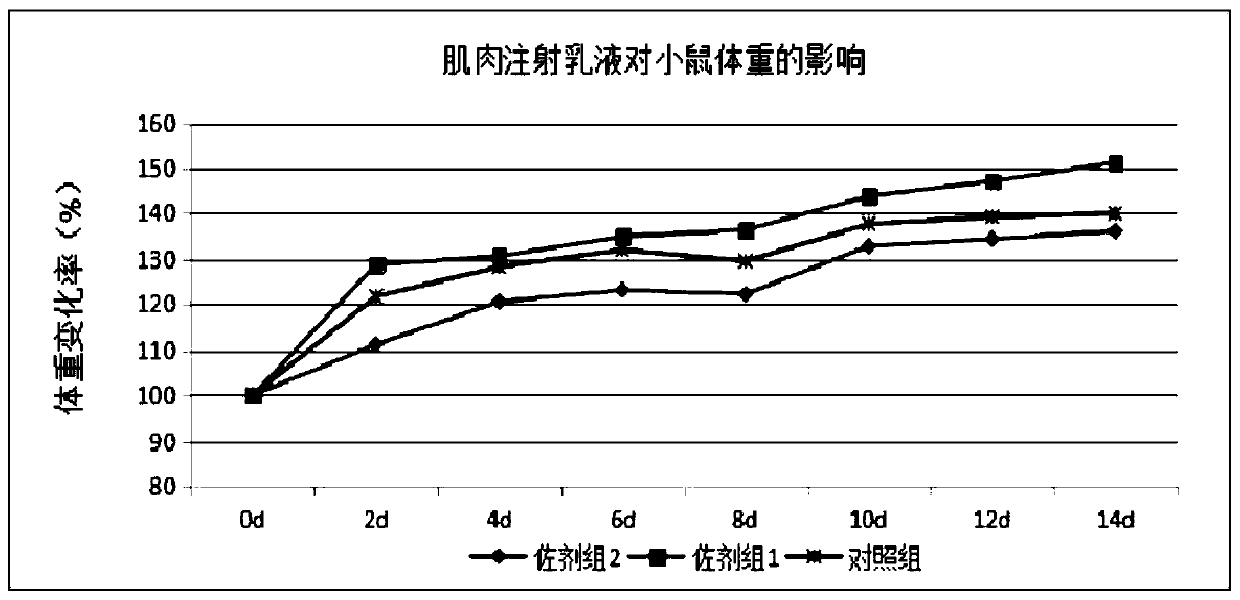

Oil-in-water adjuvant used for animal vaccines and preparation method for oil-in-water adjuvant

PendingCN111110840AHigh purityReduce dosageEmulsion deliveryAntibody medical ingredientsBiotechnologyPolyoxyethylene castor oil

The invention provides an oil-in-water adjuvant used for animal vaccines and a preparation method for the oil-in-water adjuvant, and belongs to the technical field of biological product-like animal vaccines. The oil-in-water adjuvant used for the animal vaccines comprises the following raw materials by weight percent: 80.7%-89.5% of mineral oil, 2.1%-2.5% of span 80, 3.0%-5.3% of tween 85, 1.5%-3.5% of lauroyl macrogolglycerides, 0.5%-4.7% of polyglyceryl-6 caprylate and 2.2%-3.6% of polyoxyethylated castor oil. The oil-in-water adjuvant is simple and convenient to prepare, easy to obtain andlow in cost; prepared vaccines are low in viscosity, easy and safe to inject, stable in quality and small in grain size, can reach a nanoscale, and can induce temporary and permanent immunity; and theoil-in-water adjuvant is a safe adjuvant which can be used for poultry and livestock vaccines.

Owner:四川诺顺科技有限公司

Method for preparing low-pour-point lubricant additive from low-priced cotton seed oil

InactiveCN102978011BHigh yieldHigh purityFatty acid esterificationAdditivesDistillationCalcium formate

The invention discloses a method for preparing a low-pour-point lubricant additive from low-priced cotton seed oil. The method comprises the following steps: mixing cotton seed oil, methanol and potassium hydroxide so as to prepare fatty acid methyl esters, uniformly mixing the fatty acid methyl esters, formic acid and petroleum ethers at room temperature, stirring and heating the obtained mixture, dripping a mixture of hydrogen peroxide and phosphoric acid into the obtained mixture, standing the obtained product to carry out delamination, separating a water layer, washing an oil layer by using water until the oil layer is neutral, and carrying out reduced pressure distillation to obtain colorless transparent oily epoxidized fatty acid methyl esters, wherein the epoxy value is greater than 4-7, the iodine value is less than 2-0, the acid value is less than 1, and the yield is 90-94%; adding calcium carbonate into a residual formic acid solution after reaction so as to obtain calcium formate which can be recycled; and carrying out esterification reaction on the epoxidized fatty acid methyl esters so as to obtain epoxidized fatty acid methyl ester mixed fatty acid esters. According to the method disclosed by the invention, atalyst application amount is low, the process is clean, the implementation conditions are simple, and the mass production can be implemented conveniently.

Owner:深圳市四方精细化工有限公司

Preparation method and application of a three-dimensional hierarchical porous nitrogen-doped carbon-coated silicon composite material

ActiveCN107611411BGood lookingImprove cycle stabilityCell electrodesSecondary cellsElectrical batteryMetal framework

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

A kind of mixed biomass molding fuel and molding method thereof

InactiveCN103602359BRealize resource utilizationResolve disposal issuesBiofuelsSolid fuelsFiberWaste oil

A mixed biomass briquette and its molding method, a mixed biomass briquette, using oil plant fruit press cake, or a mixture of oil plant fruit press cake and oil plant fruit oil cracking solid phase products and fibers Vegetarian biomass scraps are mixed and pressed into shape. The molding method includes the following steps: (1) pretreatment of raw materials; (2) mixing and molding; that is, mixed biomass molding fuel is obtained. The mixed biomass briquette fuel of the present invention has a high combustion rate, which can solve the problem of oil plant fruit processing waste waste disposal; the molding process has low energy consumption, low equipment loss, and is convenient for large-scale continuous production, and is convenient for transportation and storage; high strength, convenient Transportation and use; The molding method of the mixed biomass briquette fuel of the present invention is a deep utilization of industrial oil waste, and the production process of biomass fuel is optimized by using oil waste. It is easy to operate, low in pollution, small in investment, and easy to scale up Production, less loss of equipment.

Owner:湖南欣林生物油脂工程技术有限公司

Production process for seafood extract

ActiveCN102415546BMany sites of actionIncreased site of actionFood preparationBiotechnologyMaillard reaction

The invention discloses a production process for a seafood extract. The production process comprises the following steps of: preparing meat slurry; screening enzymic preparations; preparing an enzymolysis reactor; performing enzymolysis on the meat slurry and filtering by using a filter membrane; performing Maillard reaction; embedding the seafood extract; and performing spray drying. The enzymicpreparations A and B are immobilized, so that the enzymic preparations can be repeatedly used and are not required to be inactivated at high temperature, and nutrient substances in a hydrolysate are prevented from being damaged; the seafood extract has high quality, and is easy to store and widely applied; the processing process is simple, the seafood extract is suitable for large-scale continuous production, and the production cost is reduced; and raw materials of the meat slurry can be leftovers of aquatic products, and the waste of aquatic resources is avoided.

Owner:广州传味传美信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com