Production method of membrane electrode of proton-exchange membrane fuel battery

A proton exchange membrane and fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve problems such as lack of performance, and achieve the effects of long preparation cycle, enhanced electrolyte strength, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

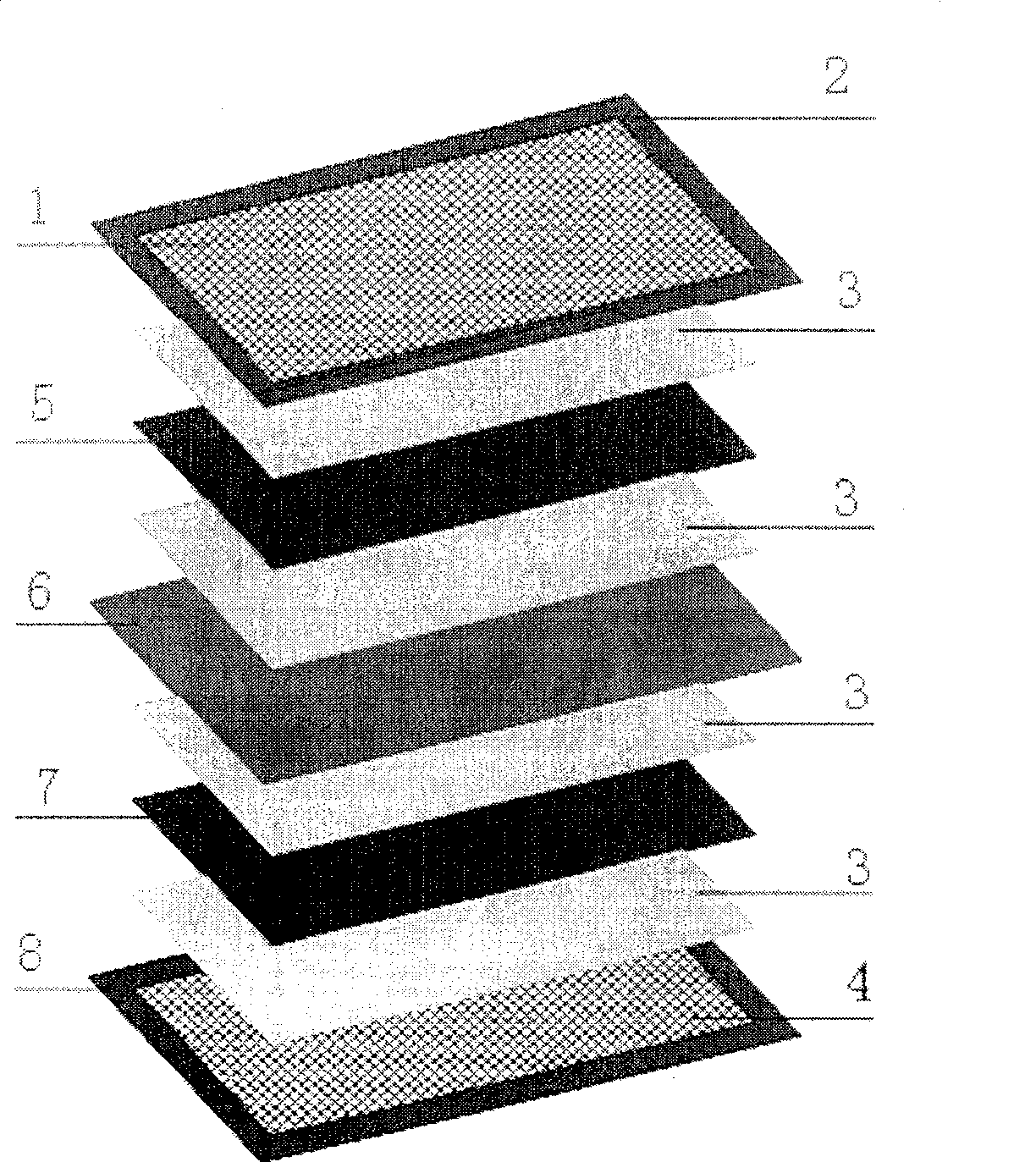

Image

Examples

Embodiment 1

[0027] 1) Cut a 5 μm polytetrafluoroethylene porous membrane (the porosity of the membrane is 90%, and the thickness is 5 μm) into a suitable size, put it in an ethanol solvent, place it in an ultrasonic wave for half an hour, and repeat it again. Cleaning and processing spare;

[0028] 2) Mix the solution containing 5% perfluorosulfonic acid resin (such as Nafion) and the Pt / C catalyst of 70% WT according to the ratio of Nafion:catalyst=1:3. The amount of anode catalyst is 0.5mg / cm 2 Calculation, the amount of cathode catalyst is 0.3mg / cm 2 Calculate, and add a certain amount of isopropanol. In order to allow the catalyst material to disperse evenly in the solution, the proportion of isopropanol should be larger, and add according to the ratio of catalyst:isopropanol=1:100:

[0029] 3) Mix the solution with ultrasonic waves, so that the catalyst material is evenly dispersed in the solution, and set aside;

[0030] 4) Spray a thin layer of adhesive on both sides of the poro...

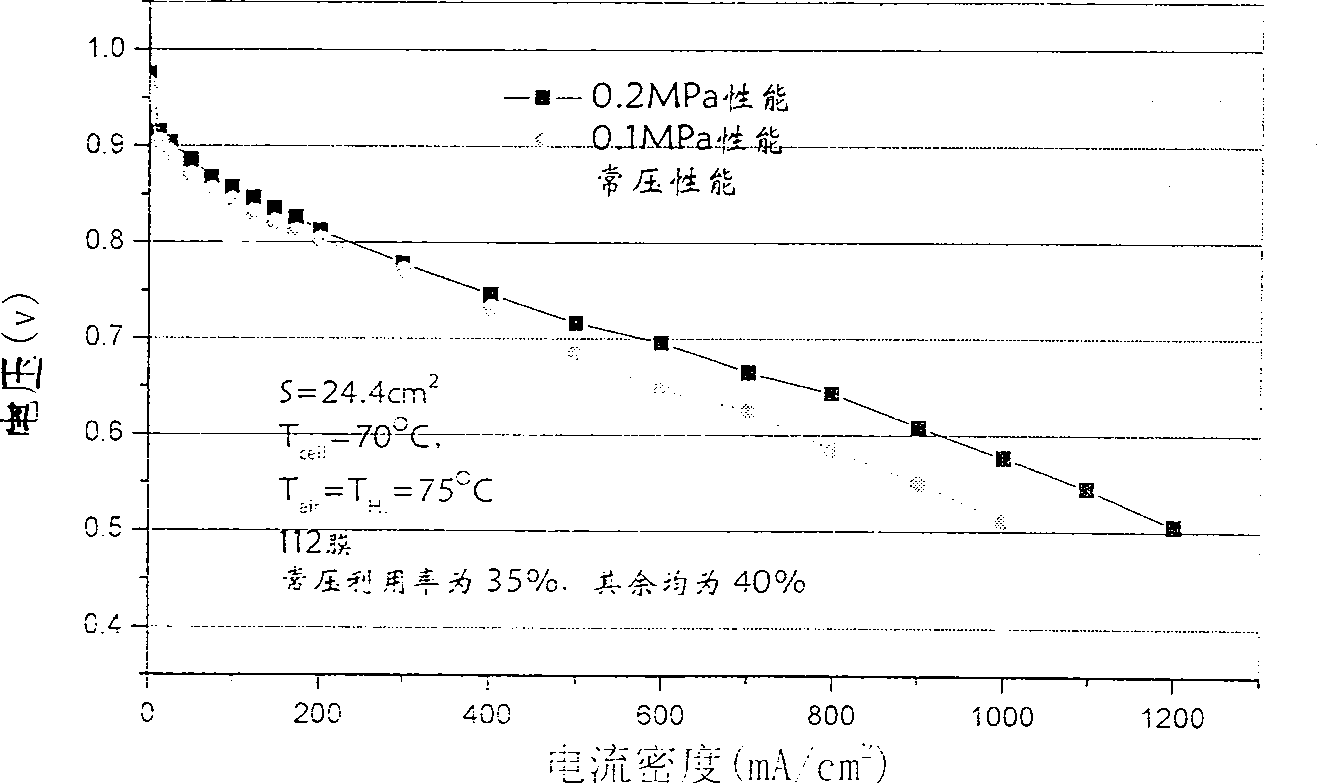

Embodiment 2

[0038] 1) repeat step 1) in embodiment one;

[0039] 2) Mix the solution containing 5% perfluorosulfonic acid resin (such as Nafion) and the Pt / C catalyst of 70% WT according to the ratio of Nafion:catalyst=1:3, and the amount of cathode catalyst is 0.75mg / cm 2 Calculation, the amount of anode catalyst is 0.75mg / cm 2 Calculate, after adding the isopropanol of the same ratio as in Example one.

[0040] 3) Repeat steps (3) to (9) in Example 1.

[0041] The performance of present embodiment MEA sees figure 2 . Depend on figure 2 It can be seen that the performance of the electrode under normal pressure conditions reaches 0.66V@500mA / cm 2 , slightly better than the performance of Example 1.

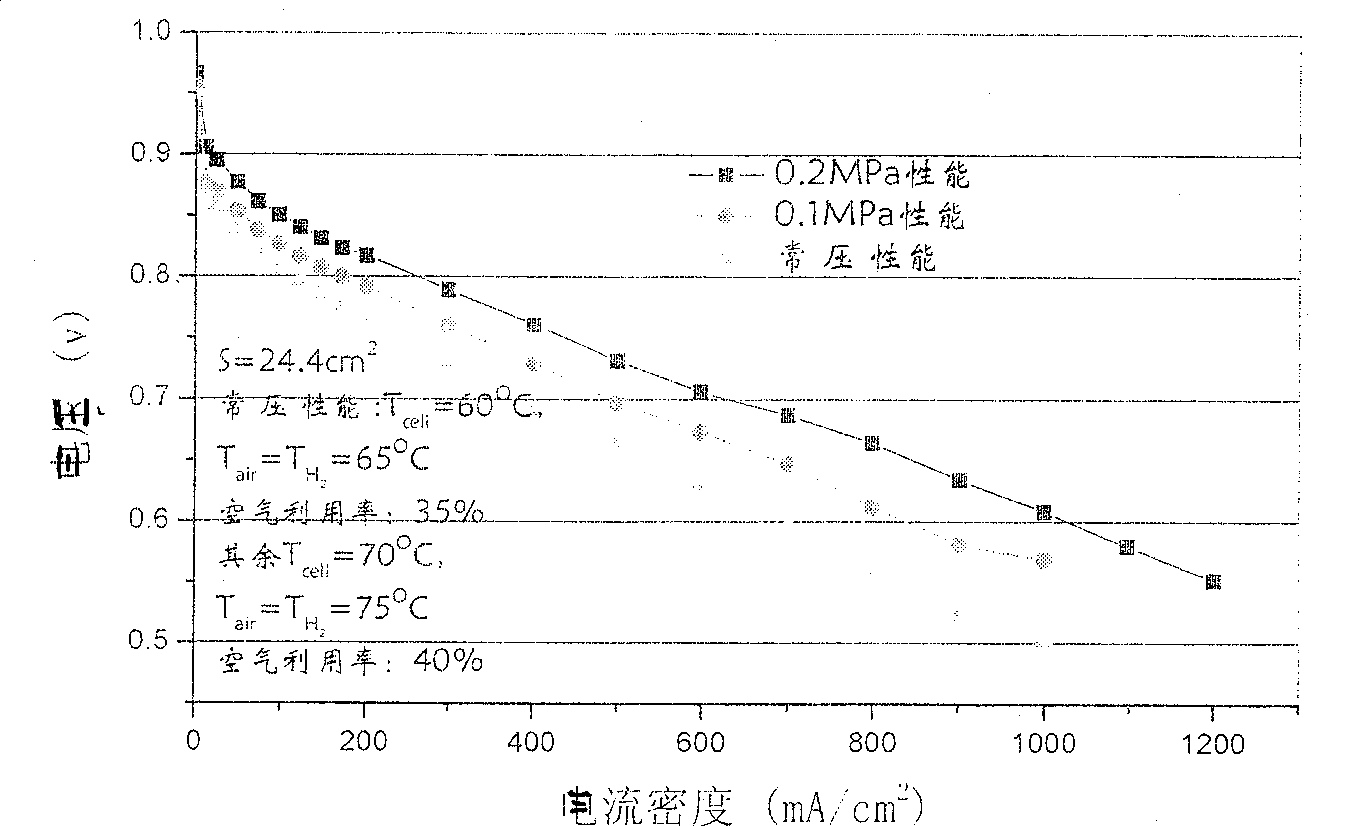

Embodiment 3

[0043] 1) repeat step 1) in embodiment one;

[0044] 2) According to step 2) of Example 1, the catalyst material was prepared, and at the same time, 10% of the total weight of the catalyst material was added to the self-humidifying agent silica, and the dispersion was uniform;

[0045] 3) Repeat steps (3) to (9) in Example 1.

[0046] The performance of present embodiment MEA sees image 3 . Depend on image 3 It can be seen that after adding self-humidifying agent, the performance of passing dry air is slightly better than that of humidified air. Therefore, the effect of self-humidification is played.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com