Oil-in-water adjuvant used for animal vaccines and preparation method for oil-in-water adjuvant

An oil-in-water and vaccine technology, which is applied in the direction of vaccines, veterinary vaccines, medical preparations with non-active ingredients, etc., can solve the problems of difficult preparation of traditional Chinese medicine and biological enhancers, narrow safety range of compound enhancers, transportation and Harsh storage conditions and other issues, to improve the level of secondary immunity, conducive to stability and antigen uptake, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An oil-in-water adjuvant for animal vaccines, by mass percentage, comprising the following raw materials: 80.7% of mineral oil, 2.2% of Span 80, 5.3% of Tween 85, 3.5% of polyethylene glycol laurate , 4.7% polyglycerol-6 caprylate, 3.6% polyoxyethylene castor oil.

[0038] The preparation method includes the following steps:

[0039] (1) respectively weigh mineral oil, Span 80, Tween 85, lauric acid macrogol glyceride, polyglycerol-6 caprylate, polyoxyethylene castor oil in proportion, for subsequent use;

[0040] (2) adding mineral oil into the reaction tank and stirring, heating;

[0041] (3) add the weighed Span 80 in the reaction tank, continue stirring, and carry out the cooling and cooling treatment to the product in the reaction tank;

[0042] (4) successively add weighed Tween 85, polyethylene glycol glyceryl laurate, polyglycerol-6 caprylate, polyoxyethylene castor oil in the reaction tank and leave standstill after stirring;

[0043] (5) The animal vaccine ...

Embodiment 2

[0046] An oil-in-water adjuvant for animal vaccines, by mass percentage, comprising the following raw materials: 85.5% of mineral oil, 2.5% of Span 80, 4.0% of Tween 85, 3.0% of polyethylene glycol laurate , 2.4% polyglycerol-6 caprylate, 2.6% polyoxyethylene castor oil.

[0047] The preparation method includes the following steps:

[0048] (1) respectively weigh mineral oil, Span 80, Tween 85, lauric acid macrogol glyceride, polyglycerol-6 caprylate, polyoxyethylene castor oil in proportion, for subsequent use;

[0049] (2) adding mineral oil into the reaction tank and stirring, heating;

[0050] (3) add the weighed Span 80 in the reaction tank, continue stirring, and carry out the cooling and cooling treatment to the product in the reaction tank;

[0051] (4) successively add weighed Tween 85, polyethylene glycol glyceryl laurate, polyglycerol-6 caprylate, polyoxyethylene castor oil in the reaction tank and leave standstill after stirring;

[0052] (5) The animal vaccine ...

Embodiment 3

[0055] An oil-in-water adjuvant for animal vaccines, by mass percentage, comprising the following raw materials: 87.3% of mineral oil, 2.2% of Span 80, 3.8% of Tween 85, 3.2% of polyethylene glycol laurate , 1.3% polyglycerol-6 caprylate, 2.2% polyoxyethylene castor oil.

[0056] The preparation method includes the following steps:

[0057] (1) respectively weigh mineral oil, Span 80, Tween 85, lauric acid macrogol glyceride, polyglycerol-6 caprylate, polyoxyethylene castor oil in proportion, for subsequent use;

[0058] (2) adding mineral oil into the reaction tank and stirring, heating;

[0059] (3) add the weighed Span 80 in the reaction tank, continue stirring, and carry out the cooling and cooling treatment to the product in the reaction tank;

[0060] (4) successively add weighed Tween 85, polyethylene glycol glyceryl laurate, polyglycerol-6 caprylate, polyoxyethylene castor oil in the reaction tank and leave standstill after stirring;

[0061] (5) The animal vaccine ...

PUM

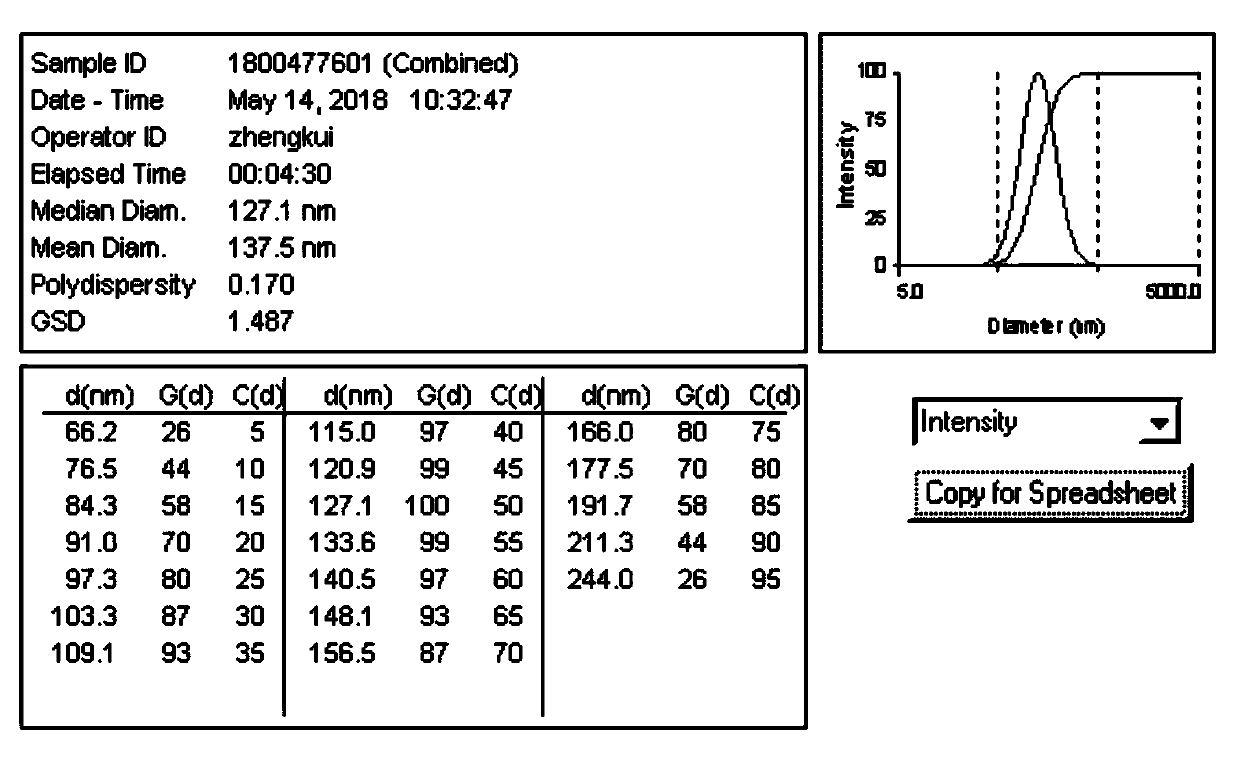

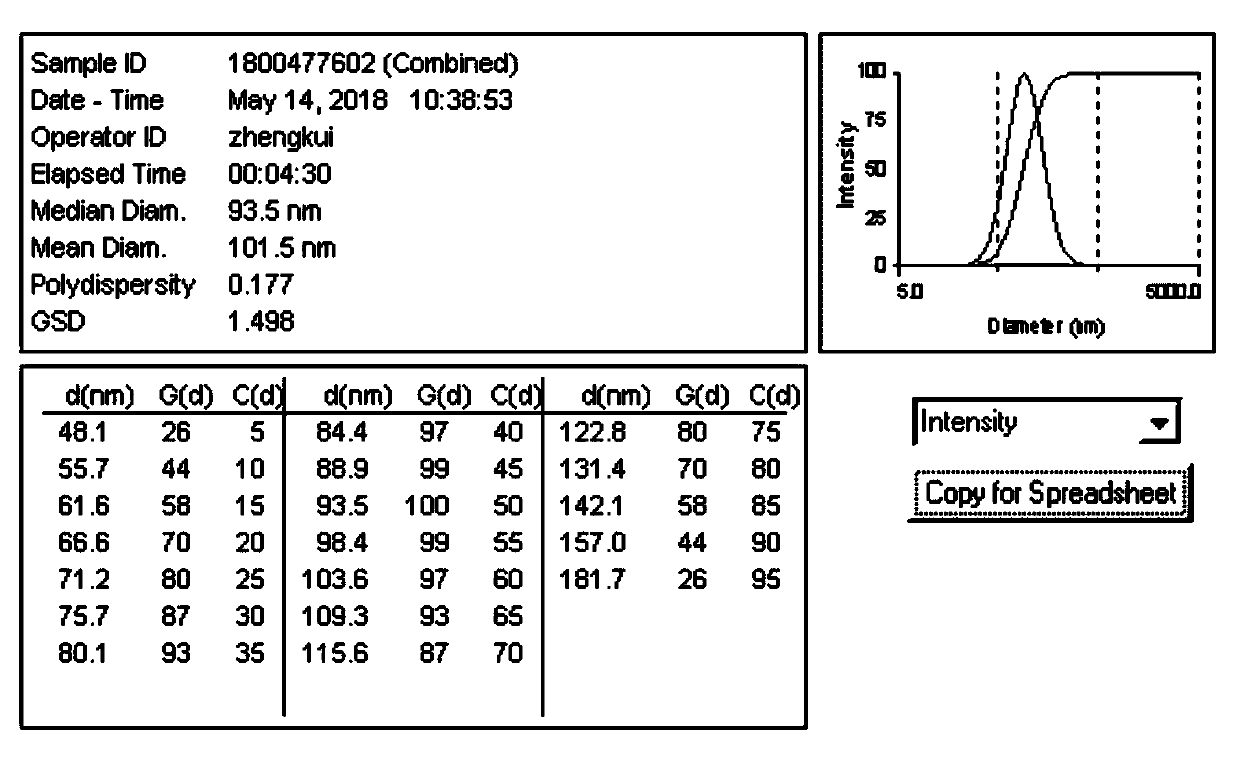

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

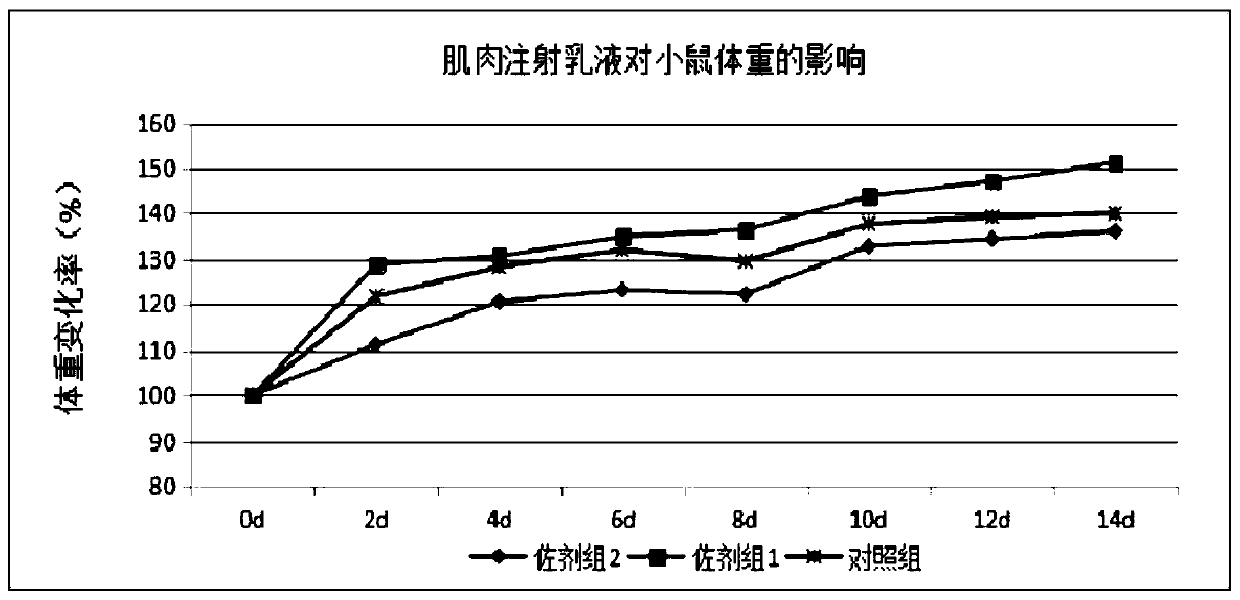

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com