A nitrogen-doped ferrous sulfide redox catalyst material and its preparation and application

A catalyst, nitrogen doping technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of poor stability, scarcity of resources, expensive Pt-based cathode catalysts, etc., and achieve low prices. , high catalytic activity, abundant reserves effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example example 1

[0029] Catalyst preparation

[0030] a, 6.3924g of sodium diethyldithiocarbamate and 1.7973g of ferrous chloride are dissolved in 100mL deionized water, react rapidly to obtain iron diethyldithiocarbamate (II) black precursor precipitate; b 1. Stir the liquid in step a at room temperature for more than 1 hour to allow it to fully precipitate, then use deionized water and absolute ethanol to wash and filter it several times, and dry it in a blast drying oven at 60°C for 12 hours to obtain Black precursor powder;

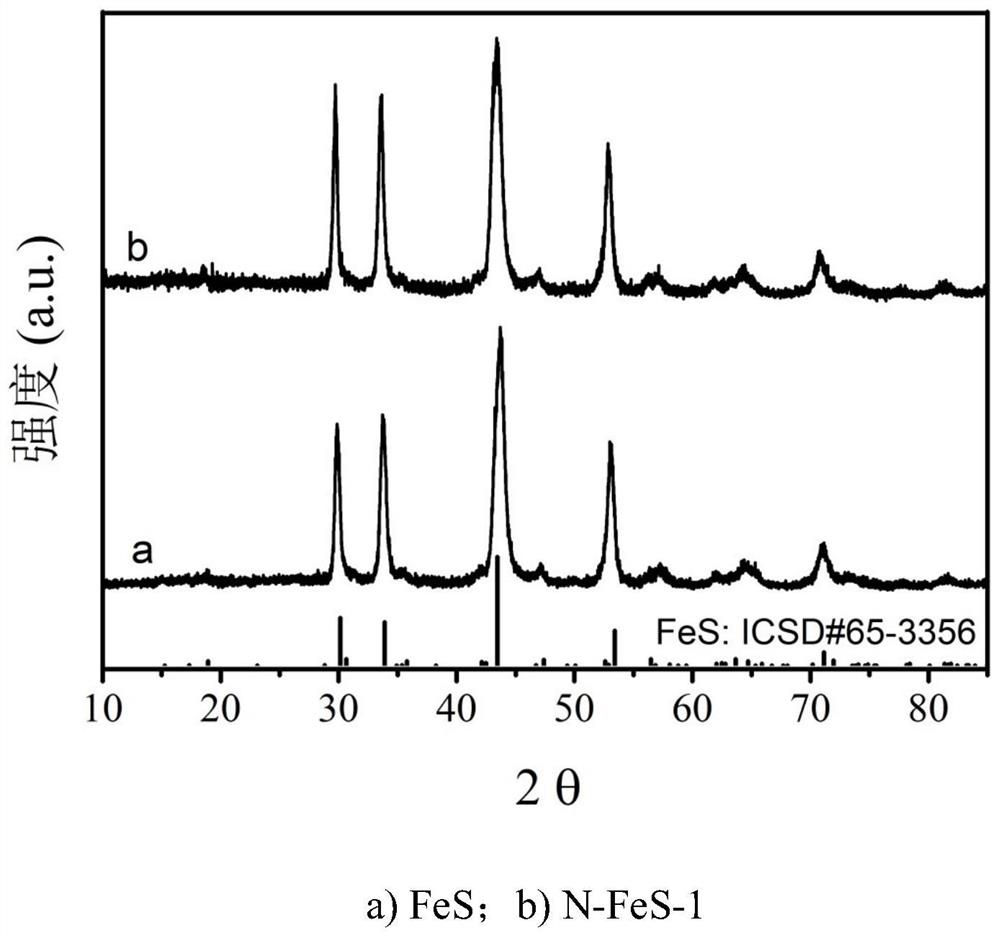

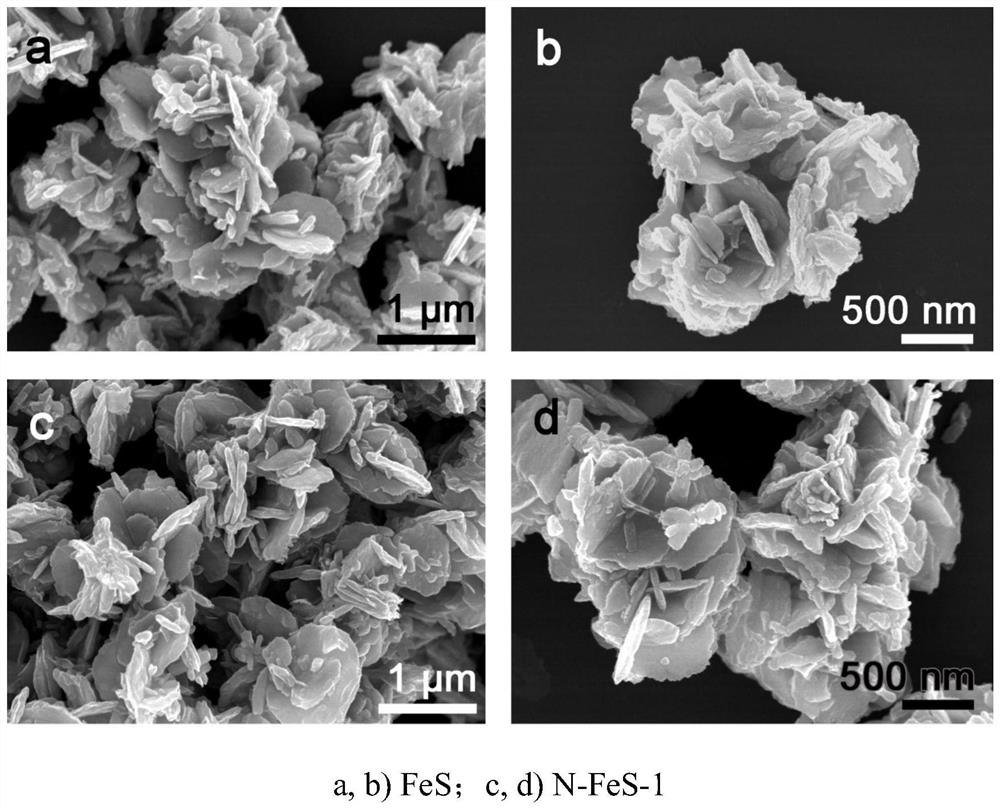

[0031] c. Put the precursor powder obtained in step b into a sealed tube furnace, and calcinate at 700° C. for 2 hours under an argon atmosphere, and the heating rate is 5° C. / min. Naturally cool down to room temperature to obtain a flower-shaped FeS microsphere catalyst;

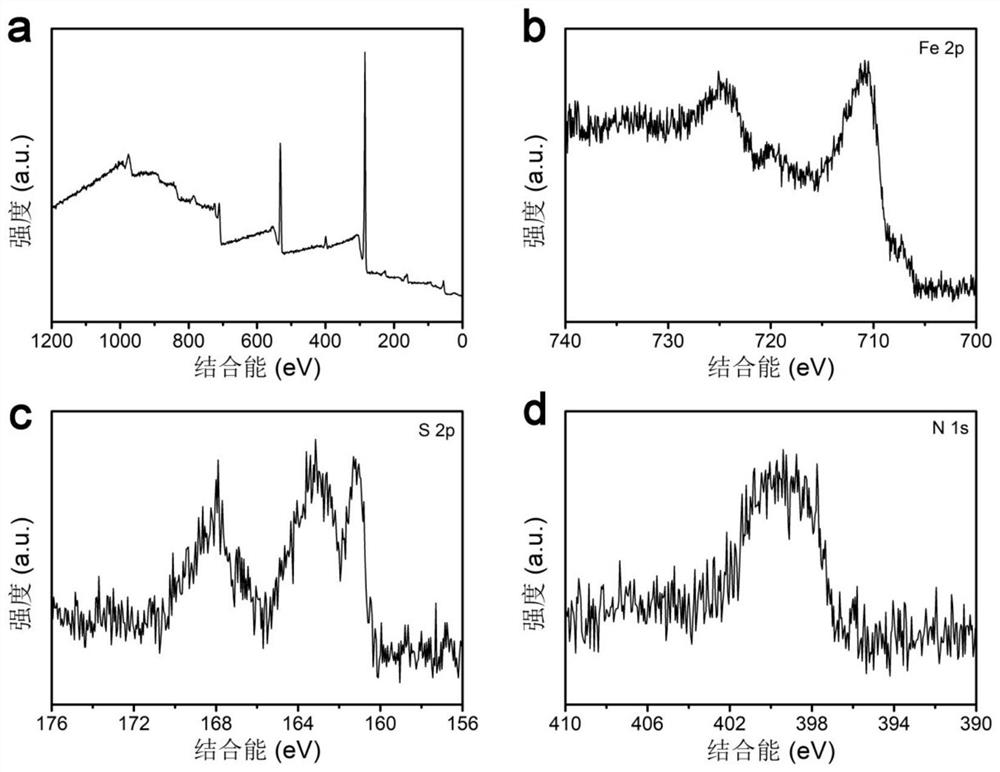

[0032] d. Place the FeS powder obtained in step c again in a sealed tube furnace, and calcinate at 400° C. for 1 h under an ammonia atmosphere, and the heating rate is 5° C. / min. After naturally...

example example 2

[0037] Catalyst preparation

[0038] a, 6.3924g of sodium diethyldithiocarbamate and 1.7973g of ferrous chloride are dissolved in 100mL deionized water, react rapidly to obtain iron diethyldithiocarbamate (II) black precursor precipitate; b 1. Stir the liquid in step a at room temperature for more than 1 hour to allow it to fully precipitate, then use deionized water and absolute ethanol to wash and filter it several times, and dry it in a blast drying oven at 60°C for 12 hours to obtain Black precursor powder;

[0039] c. Put the precursor powder obtained in step b into a sealed tube furnace, and calcinate at 700° C. for 2 hours under an argon atmosphere, and the heating rate is 5° C. / min. Naturally cool down to room temperature to obtain a flower-shaped FeS microsphere catalyst;

[0040] d. Place the FeS powder obtained in step c again in a sealed tube furnace, and calcinate at 500° C. for 1 h under an ammonia atmosphere, and the heating rate is 5° C. / min. After naturally...

example example 3

[0044] Catalyst preparation

[0045] e, 6.3924g of sodium diethyldithiocarbamate and 1.7973g of ferrous chloride were dissolved in 100mL of deionized water, reacted quickly to obtain a black precursor precipitate of diethyldithiocarbamate iron (II);

[0046] f. Stir the liquid in step a at room temperature for more than 1 hour to allow it to fully precipitate, then use deionized water and absolute ethanol to wash and filter it several times, and dry it in a blast drying oven at 60°C for 12 hours. Obtain black precursor powder;

[0047] g. Put the precursor powder obtained in step b into a sealed tube furnace, and calcinate at 700° C. for 2 hours under an argon atmosphere, and the heating rate is 5° C. / min. Naturally cool down to room temperature to obtain a flower-shaped FeS microsphere catalyst;

[0048] Electrochemical performance test

[0049] The test method is the same as in Example 1, and the specific rotating disk electrode polarization curve diagram is shown in Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com