Preparation method and application of three-dimensional (3D) hierarchical porous nitrogen-doped carbon clad silicon composite material

A silicon composite material, graded porous technology, used in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of destroying the conductive network and binder network of the electrode, the failure of active materials, and the fragmentation of silicon anode particles. High specific capacity and high rate charge and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

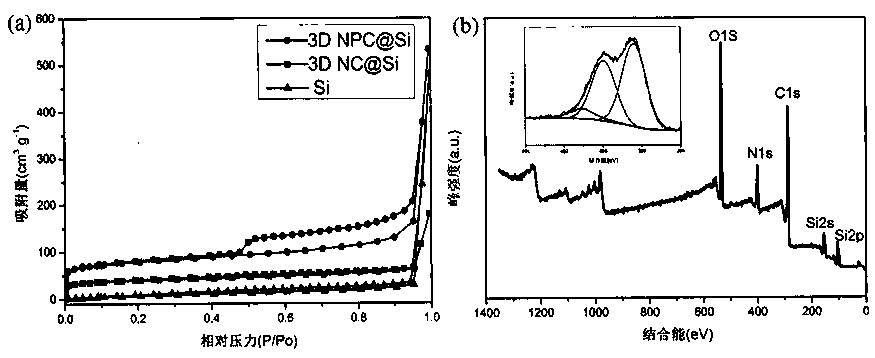

[0028] Preparation of three-dimensional hierarchical porous nitrogen-doped carbon-coated silicon microspheres:

[0029] a. Preparation of organometallic framework compound: Add 50ml of methanol solution containing 1.07g of zinc nitrate hexahydrate into 50ml of methanol solution containing 2.357g of 2-methylimidazole, stir vigorously at room temperature for 24h, centrifuge, and wash with methanol solution for 3 times, drying at 60°C;

[0030] b. Disperse 0.2g of organometallic framework compound and 0.3g of nano-silicon prepared in step a in 4ml of N,N-dimethylformamide solvent, sonicate for 15min, then add 0.2g of polyacrylonitrile, stir at room temperature for 12h, and then transfer Spray sputtering in a high-pressure sputtering device to obtain a mixture;

[0031] c. Calcining the mixture obtained in step b at a temperature of 350° C. for 3 h in a nitrogen atmosphere, and then roasting at 800° C. for 1 h, and removing metal oxides in the organometallic framework with 2M hyd...

Embodiment 2

[0035] Preparation of three-dimensional nitrogen-doped carbon-coated silicon composite (as a comparison sample):

[0036] a. Disperse 0.3g of nano-silicon in 4ml of N,N-dimethylformamide solvent, sonicate for 15min, then add 0.2g of polyacrylonitrile, stir at room temperature for 12h, and then transfer to a high-pressure sputtering device for spraying and sputtering to obtain mixture;

[0037] b. Calcining the mixture obtained in step a at a temperature of 350°C for 3h in a nitrogen atmosphere, and then roasting at a temperature of 800°C for 1h;

[0038] c. Washing and drying the product obtained in step b to obtain a three-dimensional nitrogen-doped silicon / carbon composite material.

Embodiment 3

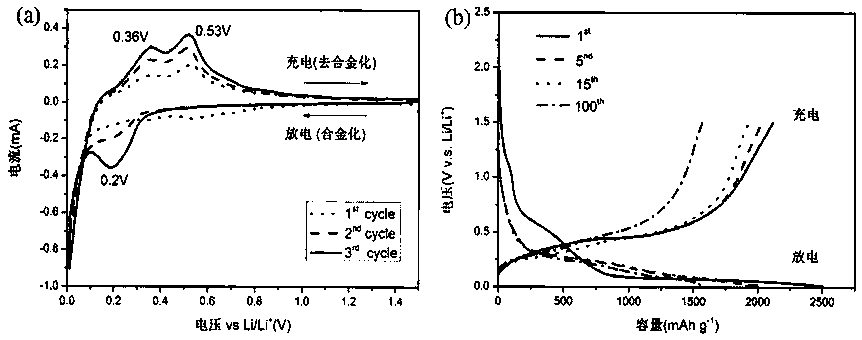

[0040] Electrochemical performance test:

[0041] Weigh 60 mg of the three-dimensional hierarchical porous nitrogen-doped silicon / carbon powder obtained by the method of the present invention as an active material, use acetylene black as a conductive agent, sodium alginate as a binder, and use deionized water as a slurry, and mix evenly , and evenly coated on the copper foil, after vacuum drying at 80°C for 12 hours, the pole piece was cut into small discs with a diameter of 10mm, and the loading capacity of the active material was 0.6-1.0mg / cm 2 , the electrolyte is 1M LiPF 6The solution is in a mixed solution of ethylene carbonate and dimethyl carbonate with a volume ratio of 1:1, and then 5 wt% of vinylene carbonate is added, a lithium metal sheet is used as a counter electrode, and Celgard 2400 is used as a diaphragm, and the solution is placed in a glove box filled with argon. In CR2025-type half-cells, the prepared pole piece was installed in a CR2025-type half-cell. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com