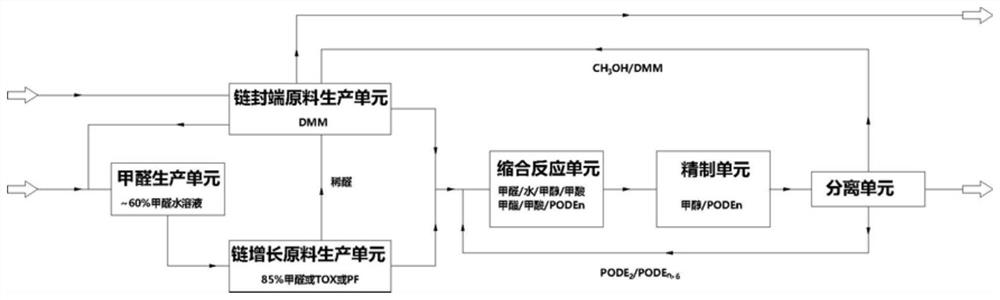

Preparation process for preparing polyoxymethylene dimethyl ether by taking methanol as raw material

A polymethoxy dimethyl ether and a preparation process technology are applied in the production field of diesel fuel additives and can solve the problems of low utilization rate of raw materials, difficulty in separation, unstable operation of devices and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

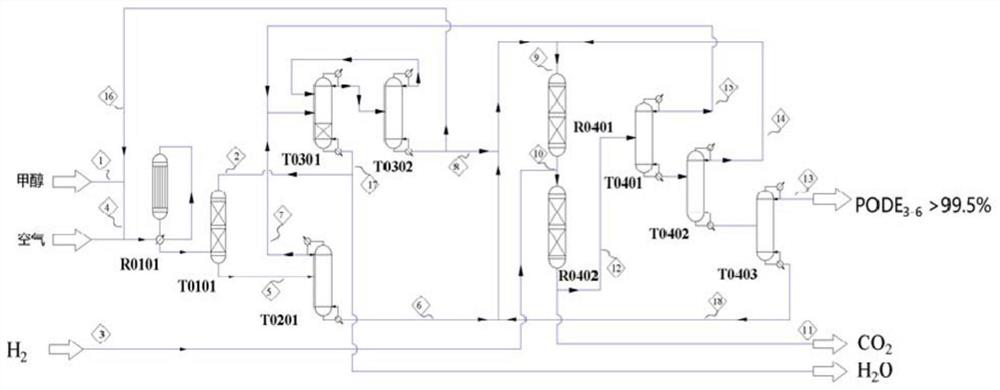

Embodiment 1

[0107] A kind of preparation technology that takes methanol as raw material to prepare polyoxymethylene dimethyl ether, comprises the steps:

[0108] (1) Formaldehyde production unit

[0109] In the formaldehyde oxidation reactor R0101, after the mixture of methanol (stream 1) and methanol recycle stream (recycle stream 16) evaporates, it is mixed with air and enters. Under the action of iron molybdenum oxidation catalyst, formaldehyde is generated at 260 ° C under normal pressure, and then Enter the formaldehyde absorption tower T0101, and the circulating water stream (stream 2) obtained by the chain-end raw material production unit is under the action of the formaldehyde absorption tower T0101 to obtain a concentrated formaldehyde aqueous solution (stream 5) with a concentration of 55.00%.

[0110] (2) Chain growth raw material production unit

[0111] The concentrated formaldehyde aqueous solution (stream 5) obtains the concentrated formaldehyde aqueous solution (stream 6)...

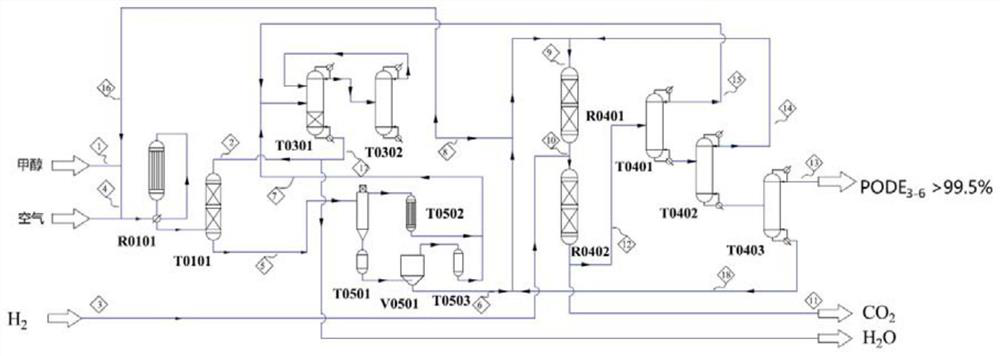

Embodiment 2

[0129] A kind of preparation technology that takes methanol as raw material to prepare polyoxymethylene dimethyl ether, comprises the steps:

[0130] (1) Formaldehyde production unit

[0131] In the formaldehyde oxidation reactor R0101, after the mixture of methanol (stream 1) and methanol recycle stream (recycle stream 16) evaporates, it is mixed with air and enters. Under the action of iron molybdenum oxidation catalyst, formaldehyde is generated at 350 ° C under normal pressure, and then Enter the formaldehyde absorption tower T0101, and the circulating water stream (stream 2) obtained by the chain-end raw material production unit absorbs formaldehyde in the formaldehyde absorption tower T0101 to obtain a concentrated formaldehyde aqueous solution (stream 5) with a concentration of 60.00%.

[0132] (2) Chain growth raw material production unit

[0133] Concentrated formaldehyde aqueous solution (stream 5) is evaporated and concentrated to 78% by thin-film evaporator T0501 ...

Embodiment 3

[0145] A kind of preparation technology that takes methanol as raw material to prepare polyoxymethylene dimethyl ether, comprises the steps:

[0146] (1) Formaldehyde production unit

[0147] In the formaldehyde oxidation reactor R0101, after the mixture of methanol (stream 1) and methanol recycle stream (recycle stream 16) is evaporated, it is mixed with air and enters. Under the action of iron-molybdenum oxidation catalyst, formaldehyde is generated at 300°C and normal pressure and enters formaldehyde The absorption tower T0101, together with the circulating water stream (stream 2) obtained from the chain-end raw material production unit absorbs formaldehyde in the formaldehyde absorption tower T0101 to obtain a concentrated formaldehyde aqueous solution (stream 5) with a concentration of 65.00%.

[0148] (2) Chain growth raw material production unit

[0149] The concentrated formaldehyde aqueous solution (stream 5) is passed into the paraformaldehyde cyclization reactor R0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com