Method for preparing waste acrylic fiber and fatty acid combined phase change material

A technology of composite phase change material and acrylic fiber waste silk, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of leakage of phase change materials of phase change materials, achieve low price, reduce environmental pollution, and improve the preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 2g of acrylic fiber waste, 6.67g of lauric acid, 1.33g of stearic acid, and 25g of N,N-dimethylformamide (DMF) into a three-necked flask, and stir and reflux at 90°C for a period of time to obtain a uniform milky white polymer. solution. When the polymer solution is injected into water, a white precipitate appears, and after drying, it becomes a composite phase change material of acrylic fiber waste silk and fatty acid.

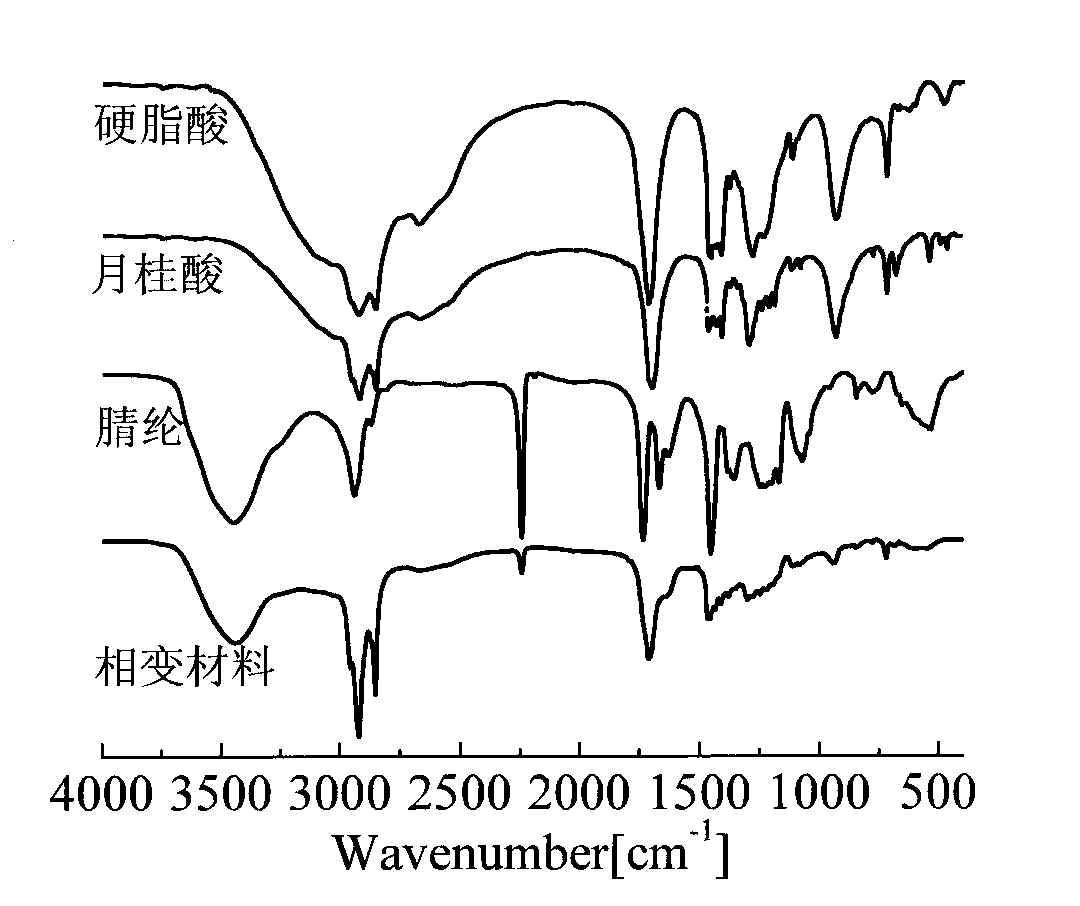

[0023] Carry out infrared spectrum (see figure 1 ) analysis, the spectrogram of the phase change material prepared by the invention is not the simple summation of three raw materials, but the disappearance of some characteristic peaks and the generation of new characteristic peaks, indicating that although the same series of fatty acids stearic acid and lauric acid Between, there will be no chemical reaction between acrylic fiber (PAN) and dibasic fatty acid, but there is a certain physical interaction between the three after mixing, such as only ...

Embodiment 2

[0026] Add 5g of acrylic fiber waste, 3.33g of lauric acid, 1.67g of stearic acid, and 25g of N,N-dimethylformamide (DMF) into a three-necked flask, and stir and reflux at 60°C for a period of time to obtain a uniform milky white polymer. solution. The polymer solution is injected into a 15% polyvinyl alcohol aqueous solution, and a white precipitate occurs,

[0027] After drying, it becomes a composite phase change material of acrylic fiber waste silk and fatty acid.

Embodiment 3

[0029] Preparation of acrylic waste silk and stearic acid composite phase change material: Add 4g of acrylic waste silk, 6g of stearic acid, and 25g of N,N-dimethylformamide (DMF) into a three-necked flask, and stir and reflux at 60°C for a period of time After that, a homogeneous milky white polymer solution was obtained. When the polymer solution is injected into water, a white precipitate appears, and after drying, it becomes a composite phase change material of acrylic fiber waste silk and fatty acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com