Boron-containing high speed steel roller and preparation method thereof

A high-speed steel and roll technology, applied in the field of boron-containing high-speed steel roll and its preparation, cast steel roll and its preparation, can solve the problems of large fluctuations in mechanical properties, poor wear resistance, etc., and achieve good machining performance and high tool consumption , the effect of low direct processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

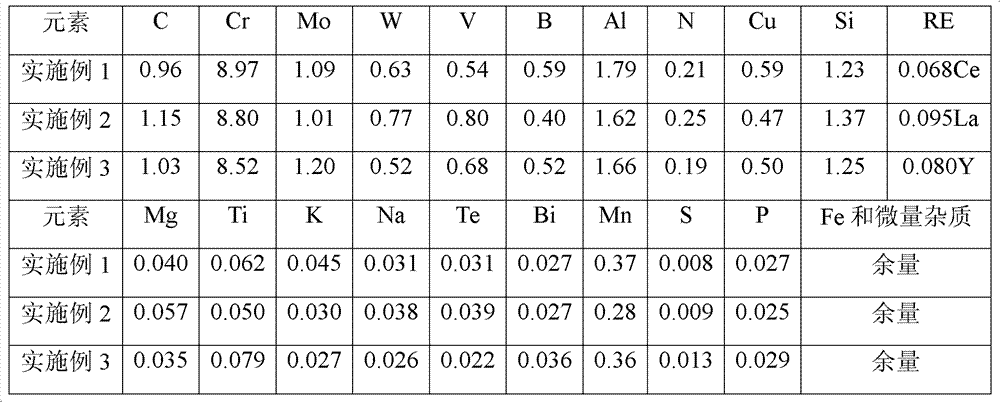

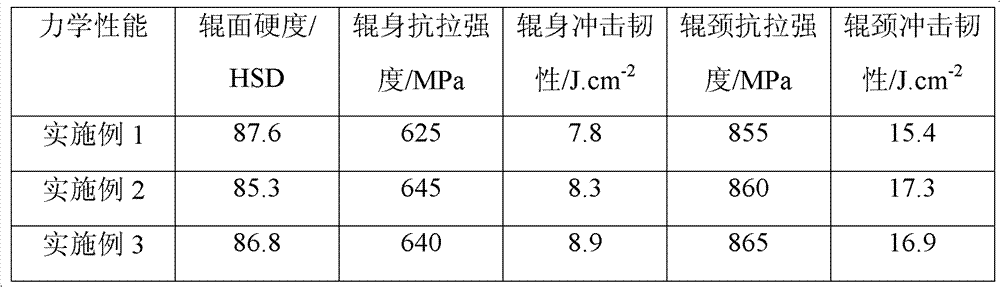

Embodiment 1

[0048] The boron-containing high-speed steel roll material is smelted in a 500-kg medium-frequency induction furnace. The specific manufacturing process steps are:

[0049] 1) First, use scrap steel, recarburizer, ferrochrome, copper plate, ferrotungsten and ferromolybdenum to mix and heat and melt. After the molten steel is melted, add ferrosilicon. When the temperature rises to 1524°C, add aluminum and nitrogen-containing ferrochrome, and then add vanadium in sequence. Iron, ferro-boron and ferro-titanium, after adjusting the components before the furnace to pass, the temperature of the molten steel is raised to 1563°C, and the slag is removed from the furnace.

[0050] 2) Crushing iron bismuth, copper telluride master alloy, potassium-containing substance, sodium-containing substance and rare earth magnesium alloy (the rare earth element is cerium) into small pieces with a particle size of less than 10mm, dried at 200°C, and placed in a ladle At the bottom, the molten steel...

Embodiment 2

[0057] The boron-containing high-speed steel roll material is smelted in a 750-kg medium-frequency induction furnace. The specific manufacturing process steps are:

[0058] 1) First, use scrap steel, recarburizer, ferrochrome, copper plate, ferrotungsten and ferromolybdenum to mix and heat and melt. After the molten steel is melted, add ferrosilicon. When the temperature rises to 1549°C, add aluminum and nitrogen-containing ferrochrome, and then add vanadium in turn. Iron, ferro-boron and ferro-titanium, after adjusting the composition before the furnace to pass, the temperature of the molten steel is raised to 1580°C, and the slag is removed from the furnace.

[0059] 2) Crushing iron bismuth, copper telluride master alloy, potassium-containing substance, sodium-containing substance and rare earth magnesium alloy (specifically, the rare earth element is lanthanum) into small pieces with a particle size of less than 10mm, dried at 180°C, and placed in a ladle At the bottom, th...

Embodiment 3

[0066] The boron-containing high-speed steel roll material is smelted with a 750 kg medium-frequency induction furnace, and the manufacturing process steps are:

[0067] 1) First, use scrap steel, recarburizer, ferrochrome, copper plate, ferrotungsten and ferromolybdenum to mix and heat and melt, then add ferrosilicon after the molten steel is melted, and when the temperature rises to 1536°C, add aluminum and nitrogen-containing ferrochrome, and then add vanadium in sequence Iron, ferro-boron and ferro-titanium, after adjusting the composition before the furnace to pass, the temperature of the molten steel is raised to 1571°C, and the slag is removed from the furnace.

[0068] 2) Crushing iron bismuth, copper telluride master alloy, potassium-containing substance, sodium-containing substance and rare earth magnesium alloy (the specific rare earth element is yttrium) into small pieces with a particle size of less than 10mm, dried at 190°C, and placed in a ladle At the bottom, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com