Preparation method and use of nitrogen-doped carbon-surface-loaded mononuclear metal catalyst

A metal catalyst, surface-loaded technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as catalyst problems, and achieve the effect of high stability and methanol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Catalyst preparation

[0027] a, impregnation method: loading ferric chloride on the surface of 1g porous silica;

[0028] b. Dry the silicon dioxide impregnated with ferric chloride in step a at a temperature of 110° C. and disperse it in a mixed solution of 8.7 g of ethylenediamine and carbon tetrachloride, and reflux at a temperature of 90° C. for 6 hours to obtain a mixture;

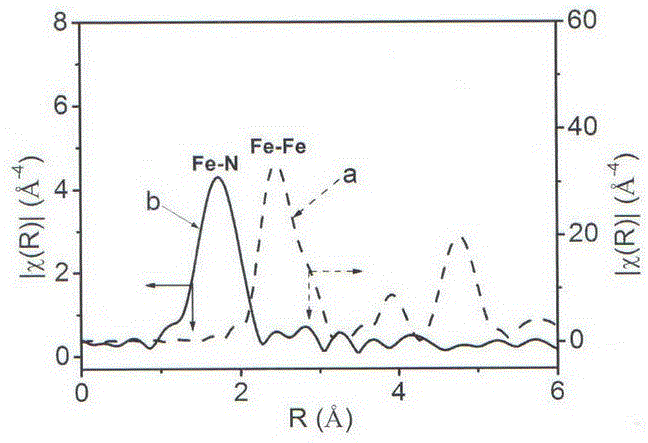

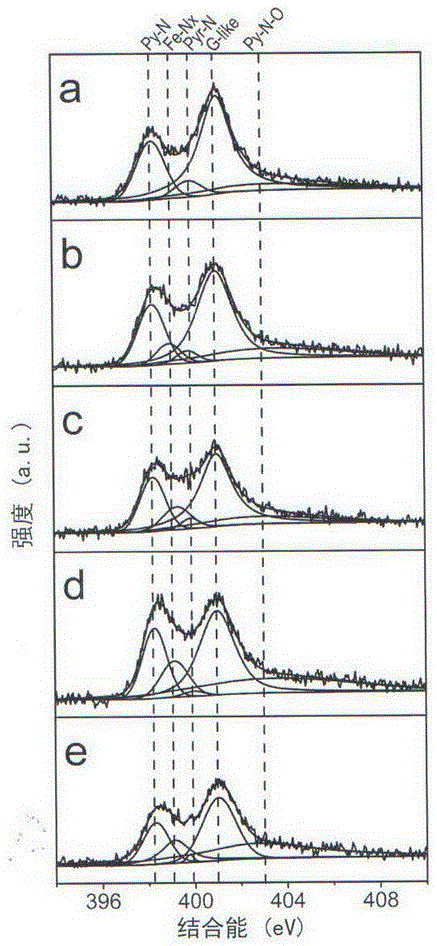

[0029] c. After roasting the mixture obtained in step b at a temperature of 900°C in a nitrogen atmosphere for 3 hours, remove the silica with 8% hydrofluoric acid, wash and dry, and obtain a mononuclear dispersed nitrogen complex supported on the surface of nitrogen-doped carbon Iron catalyst (Fe / NC-X, X represents the iron percentage content of silica load), the X-ray synchrotron radiation result of the product obtained sees figure 1 , X-ray Photoelectron Spectroscopy see figure 2 .

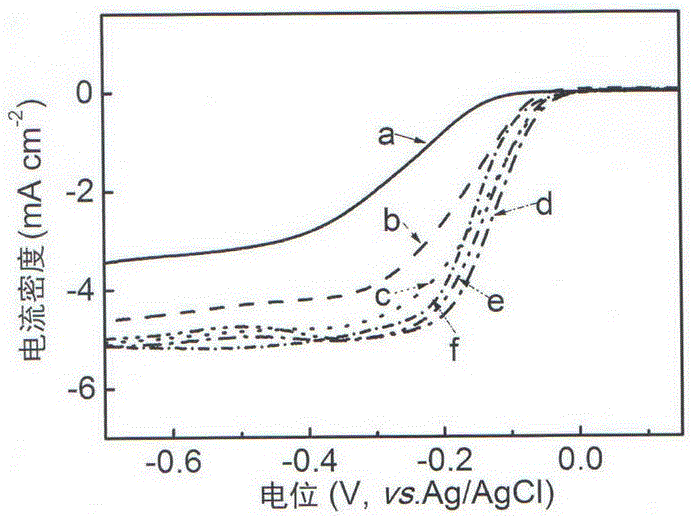

[0030] Electrochemical performance test

[0031] Weigh 5 mg of the catalyst powder obtained in Example ...

Embodiment 2

[0034] Catalyst preparation

[0035] a, impregnation method: support copper chloride on the surface of 1g silica nanoparticles (Cu loading is 10%);

[0036] b. The silicon dioxide nanoparticles impregnated with copper chloride in step a were dried at a temperature of 110° C., dispersed in 8.7 g of ethylenediamine and carbon tetrachloride mixed solution, and refluxed at a temperature of 90° C. for 6 hours to obtain a mixture;

[0037] c. After roasting the mixture obtained in step b at a temperature of 900° C. for 3 hours in a nitrogen atmosphere, remove silicon dioxide with 8% hydrofluoric acid, and use FeCl 3 solution to remove Cu nanoparticles;

[0038] d. After washing and drying the product obtained in step c, a nitrogen-doped carbon (NC) surface-supported mononuclear dispersed nitrogen-coordinated copper catalyst (Cu / NC-10) is obtained.

[0039] Electrochemical performance test

[0040]Weigh 5 mg of the catalyst powder obtained in Example 2, and disperse it in 500 uL o...

Embodiment 3

[0043] Catalyst preparation

[0044] a, impregnation method: loading cobalt chloride (Co loading is 10%) on the surface of 0.5g porous silica;

[0045] b. The porous silica impregnated with metal cobalt chloride in step a was dried at a temperature of 110° C., dispersed in 8.7 g of ethylenediamine and carbon tetrachloride mixture, and refluxed at a temperature of 90° C. for 6 hours to obtain a mixture;

[0046] c. Calcining the mixture obtained in step b at a temperature of 900° C. for 3 h in a nitrogen atmosphere, and removing silicon dioxide with a concentration of 8% hydrofluoric acid;

[0047] d. After washing and drying the product obtained in step c, a nitrogen-doped carbon (NC) surface-supported mononuclear dispersed nitrogen-coordinated cobalt catalyst (Co / NC-10) is obtained.

[0048] Electrochemical performance test

[0049] Weigh 5 mg of the catalyst powder obtained in Example 3, and disperse it in 500 uL of isopropanol aqueous solution containing 0.05% naphthol so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com