Two-step method for cultivating microalgae by using light conversion film

A technology of light conversion film and microalgae, which is applied in the direction of microorganism-based methods, microorganisms, single-cell algae, etc., to achieve the effects of fast transformation, improved transformation speed and product accumulation, and shortened transformation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

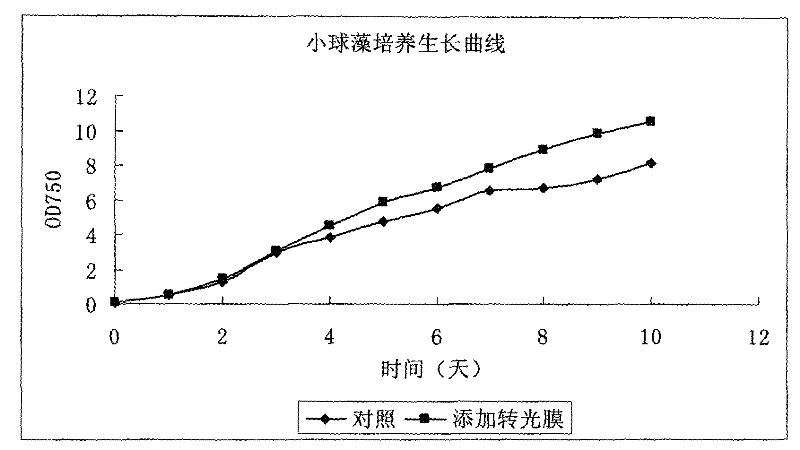

[0030] Example 1: Cultivation of Chlorella in two steps with light-converting film

[0031] Taking Chlorella (a kind of green algae) as an object, the first and second light conversion films are covered on the outer wall of the photoreactor to carry out two-step culture.

[0032] The first light conversion film (purchased from Jiangsu Mikeduo Company, the base material of the light conversion film is polyethylene SH150, the general formula of the light conversion agent is UV>RI-MS, the excitation spectrum peaks are at 300nm, 350nm and 550nm, and the emission spectrum peaks are at 650nm, the mass content of the light conversion agent in the base material is about 1.0%, and the thickness of the film is 0.10-0.16mm) covering the outer wall of the 10L bubble reactor, and the same reactor without the light conversion film is used as a control. Improved SM medium (medium composition and its content see Table 1-6 below), inoculate logarithmic algal species (formed 5-7 days after tr...

Embodiment 2

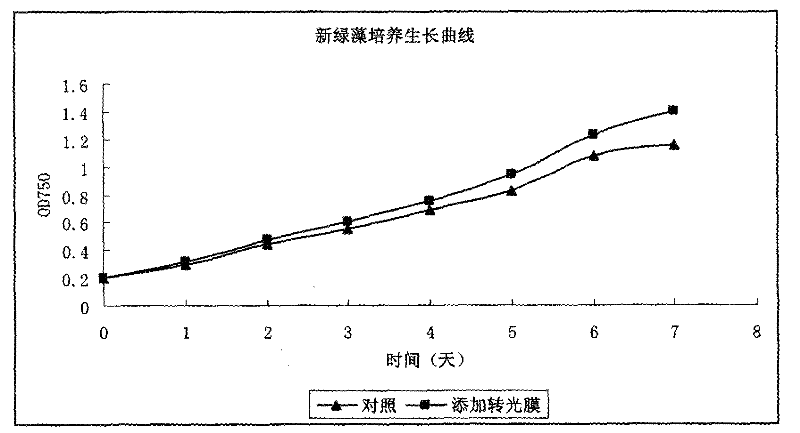

[0051] Embodiment 2: Two-step method of light conversion membrane to cultivate new green algae

[0052] As in Example 1, the cultured algae were Neochloris oleoabundans (purchased from UTEX), using BBM medium (reference: Stein, J. (ED.) Handbook of Phycological methods. Culture methods and growth measurements. CambridgeUniversity Press. 448 pages). The first light conversion film used mainly converts ultraviolet light into red light. It is purchased from Jiangsu Mikoduo Company. The base material of the light conversion film is polyethylene SH150. The general formula of the light conversion agent is UV>RI-MS, and the excitation spectrum peak At 300nm, 350nm and 550nm, the peak of the emission spectrum is at 650nm, the mass content of the light conversion agent in the base material is about 1.0%, and the thickness of the film is 0.10-0.16mm; the second light conversion film mainly converts ultraviolet light into blue light, the manufacturer As above, the base material of the...

Embodiment 3

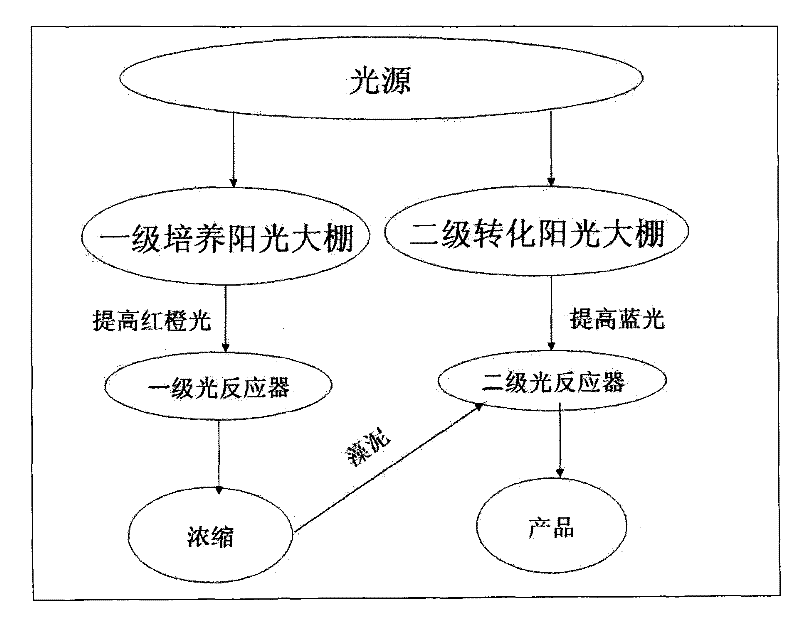

[0053] Embodiment 3: Use the two-stage sunshine greenhouse covered with the first and second light conversion film to carry out two-step method to cultivate Chlorella

[0054] The culture objects are the same as those in Example 1, both being Chlorella. The general formula of the first-level greenhouse is UV>RI-MS. The mass content of the light-changing agent in the base material is about 1.0%, and the thickness is 0.10-0.16mm. The base material is polyethylene SH150, the excitation spectrum peak of the light transfer agent is at 300nm, 350nm and 550nm, and the emission spectrum peak is at 650nm). Curtains to adjust the excessive light at noon. There is a water curtain cooling system inside the greenhouse, and the reactor used inside the greenhouse is a glass tube bubbling reactor, and the culture system is 10m 3 , culture Chlorella with SM medium, inoculate the initial OD750 at 0.40, control the light intensity with sunshade curtains and reflective curtains, from the init...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com