Metal carrier loaded copper-based SCR catalyst and preparation method thereof

A technology of SCR catalyst and metal carrier, which is applied in the field of SCR denitrification, can solve the problems of complex metal carrier pretreatment methods, multiple coating times, and high coating peeling rate, and achieves convenience for large-scale continuous production, simple production process, and coating Even layer distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

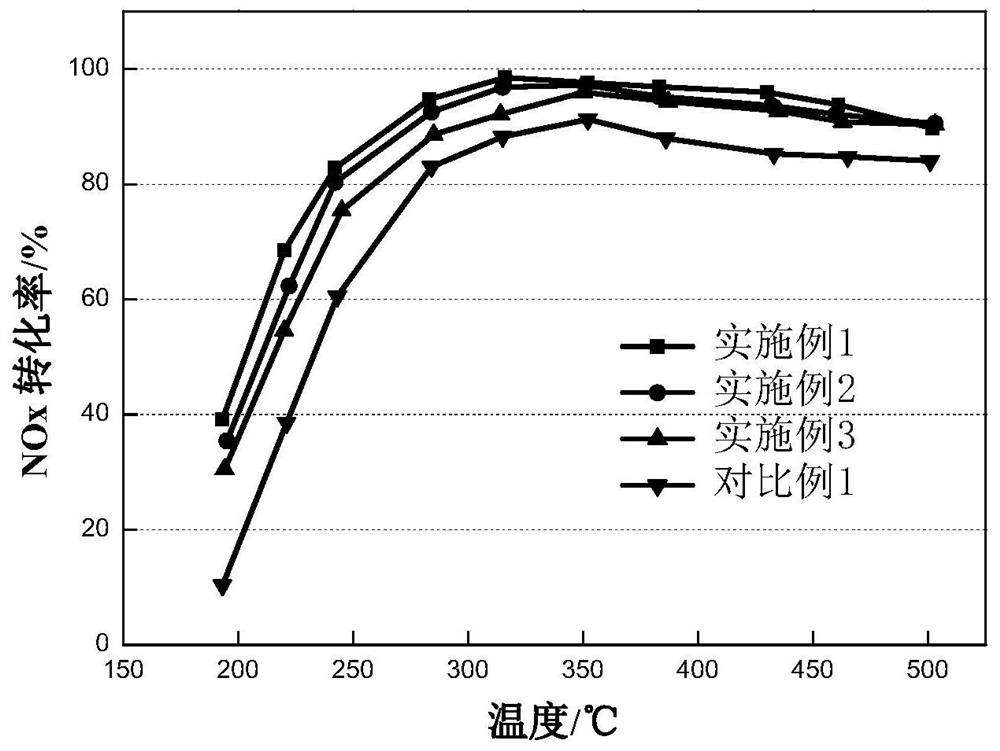

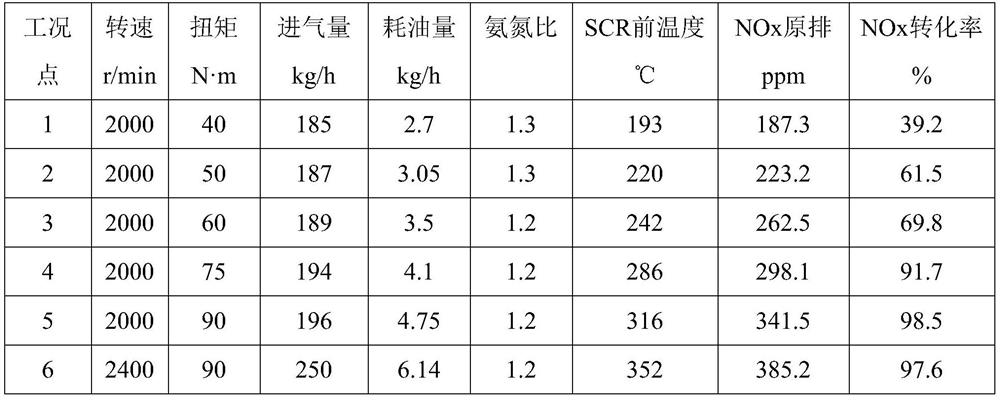

Examples

Embodiment 1

[0044] A method for preparing a copper-based SCR catalyst supported by a metal carrier, comprising the following steps:

[0045] (1) Metal carrier pretreatment

[0046] Calcinate the metal carrier at 600°C in an air atmosphere for 0.5h, take it out and cool it to room temperature naturally, wherein the metal carrier adopts a straight-through structure, and the material is SUS304;

[0047] (2) Preparation of molecular sieve slurry

[0048]Weigh the copper-containing molecular sieve according to the calculated amount, add 1.5 times of its weight in deionized water, stir well and add 0.1% citric acid, 3% polyethylene glycol, 2% silica sol and 1% titanium sol of the molecular sieve weight , until evenly stirred; the molecular sieve is SSZ-13 crystal form, the design coating amount is 160g / L, the silicon-aluminum ratio is 12, the copper content is 4.0wt%, and contains 5wt% lanthanum.

[0049] (3) Molecular sieve slurry coating

[0050] Use negative pressure suction to guide the ...

Embodiment 2

[0058] A method for preparing a copper-based SCR catalyst supported by a metal carrier, comprising the following steps:

[0059] (1) Metal carrier pretreatment

[0060] Roast the metal carrier at 550°C in an air atmosphere for 1 hour, take it out and cool it down to room temperature naturally. The metal carrier has a wall-flow structure and the material is SUS310s;

[0061] (2) Preparation of molecular sieve slurry

[0062] Take by weighing the copper-containing molecular sieve according to the calculated amount, add 2 times of its weight in deionized water, add 1% acetic acid, 5% ammonium bicarbonate, 1% titanium sol and 1% aluminum sol by the weight of the molecular sieve after stirring, until Stir evenly, the molecular sieve is a combination of SAPO-34 and SSZ-13 crystal forms, the designed coating amounts of the two are 40g / L and 100g / L respectively, the comprehensive silicon-aluminum ratio is 8, the copper content is 3.5wt%, and contains 0.1wt % cerium;

[0063] (3) Mo...

Embodiment 3

[0068] A method for preparing a copper-based SCR catalyst supported by a metal carrier, comprising the following steps:

[0069] (1) Metal carrier pretreatment

[0070] The carrier was roasted at 500°C in an air atmosphere for 1.5h, and then cooled to room temperature naturally after taking it out. The metal carrier is a partial flow structure, and the material is SUS441;

[0071] (2) Preparation of molecular sieve slurry

[0072] Weigh the copper-containing molecular sieve according to the calculated amount, add 2.5 times of its weight in deionized water, stir evenly, add 2% salicylic acid, 2% ammonium chloride, and 8% zirconium sol by the weight of the molecular sieve until it is evenly stirred; molecular sieve It is a combination of SSZ-39 and SSZ-13 crystal forms, the designed coating amounts of the two are 60g / L and 40g / L respectively, the comprehensive silicon-aluminum ratio is 25, the copper content is 3.0wt%, and it contains 2wt% zirconium and 2wt% lanthanum.

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com