Single-screw extrusion cavity with good mixing effect

A single-screw extrusion and mixing technology, which is applied in the field of powder coating production equipment, can solve the problems of inability to achieve the mixing effect, low output efficiency, and short residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

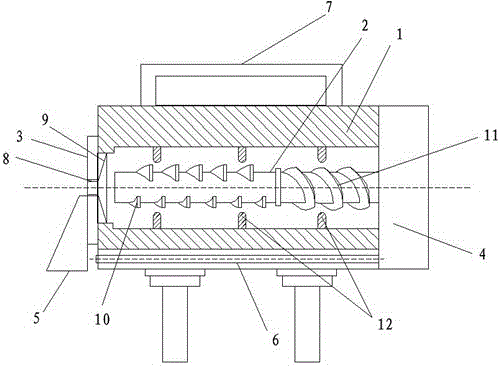

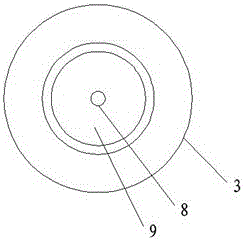

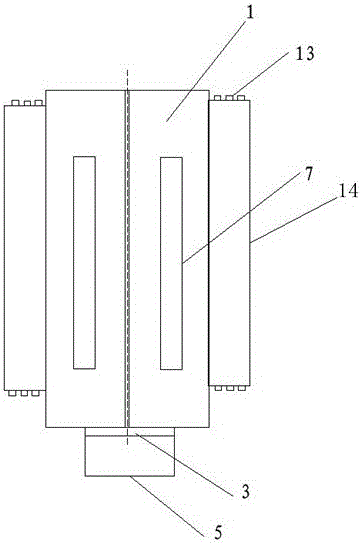

[0019] Embodiment 1: as figure 1 with 3 Shown is a single-screw extrusion chamber with high mixing effect. The interior of the extrusion chamber adopts a single threaded extrusion rod 2, and the threaded extrusion rod 2 is connected to the transmission device 4 on the side of the extrusion chamber. Above, the extrusion chamber includes a threaded extrusion rod 2, a sealed chamber housing 1, a cooling chamber housing 14, an extrusion port sealing plate 3 and a material introduction baffle 5, and the sealed chamber housing 1 consists of two pieces The rectangular housing is hermetically combined by the rotating shaft 6 at the bottom. A cylindrical sealing chamber is arranged inside the sealed chamber housing 1. Cooling chamber housings 14 are provided on both sides of the sealed chamber housing 1. The outlet end of the sealed cavity housing 1 is provided with an extrusion port sealing plate 3, the diameter of the extrusion port 8 of the extrusion port sealing plate 3 is 1.1-1....

Embodiment 2

[0020] Embodiment 2: as figure 1 As shown, the threaded extrusion rod 2 is provided with two segments of extrusion threads, which are discontinuous extrusion threads 10 and continuous extrusion threads 11 respectively, and the continuous extrusion threads 11 are arranged at the end of the threaded extrusion rod 2 At the connecting end of the transmission device 4 , the discontinuous extrusion thread 10 is arranged at the extrusion port end of the threaded extrusion rod 2 . The thread breaking distance of the intermittent extrusion thread 10 is 1.3-1.5cm; since the discharge efficiency of the continuous extrusion thread 11 is low, the intermittent extrusion thread added at the exit end of the extrusion chamber 10 to facilitate the discharge of raw materials; because the aperture of the extrusion port 8 of the present invention is small, the internal pressure of the cavity is relatively large, and the mixing effect of the raw materials is good. -0.2cm, improve the discharge ef...

Embodiment 3

[0021] Embodiment 3: as figure 1 , 2 As shown in and 3, the extrusion port sealing plate 3 is set on the outlet end of the sealed cavity housing 1 through a nut structure, and the inner side of the cylindrical extrusion port 8 on the extrusion port sealing plate 3 is provided with a tapered material introduction port 9 . The diameter of the small end of the tapered material introduction port 9 is the same as that of the extrusion port 8, and the diameter of the large end is smaller than the inner diameter of the sealing cavity 1 by 0.8-1.0 cm; the extrusion port sealing plate 3 is mainly used to control the discharge diameter of the extrusion port 8 and the mixing pressure inside the sealed chamber 1 to ensure the mixing effect inside the sealed chamber. Under the action of pressure, the extrusion port 8 that facilitates the entry of raw materials through the tapered material introduction port 9 has a good extrusion effect and prevents raw materials from remaining inside the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com