Pressure roller for biomass briquetting machine and machining method for pressure roller

A molding device and biomass technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of reducing equipment work efficiency, equipment downtime, low wear resistance, etc., to reduce excess consumption and the workload of workers replacing pressure wheels , improve the overall life, improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

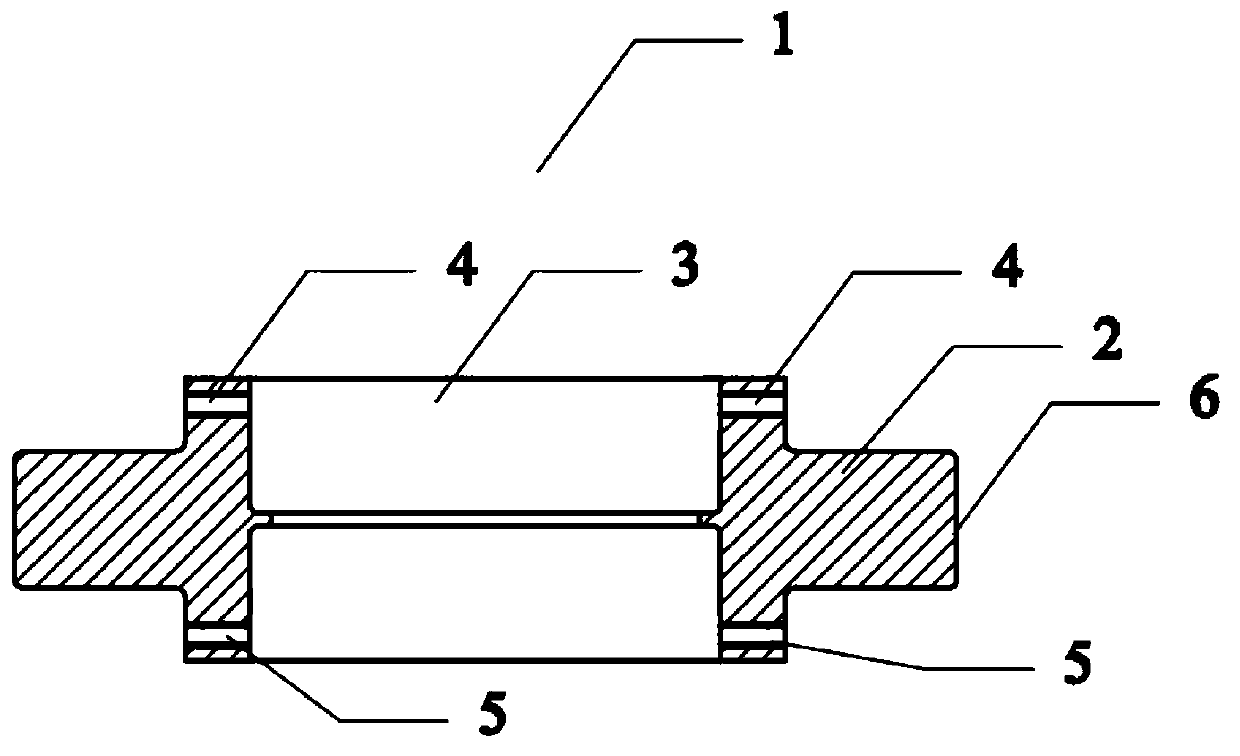

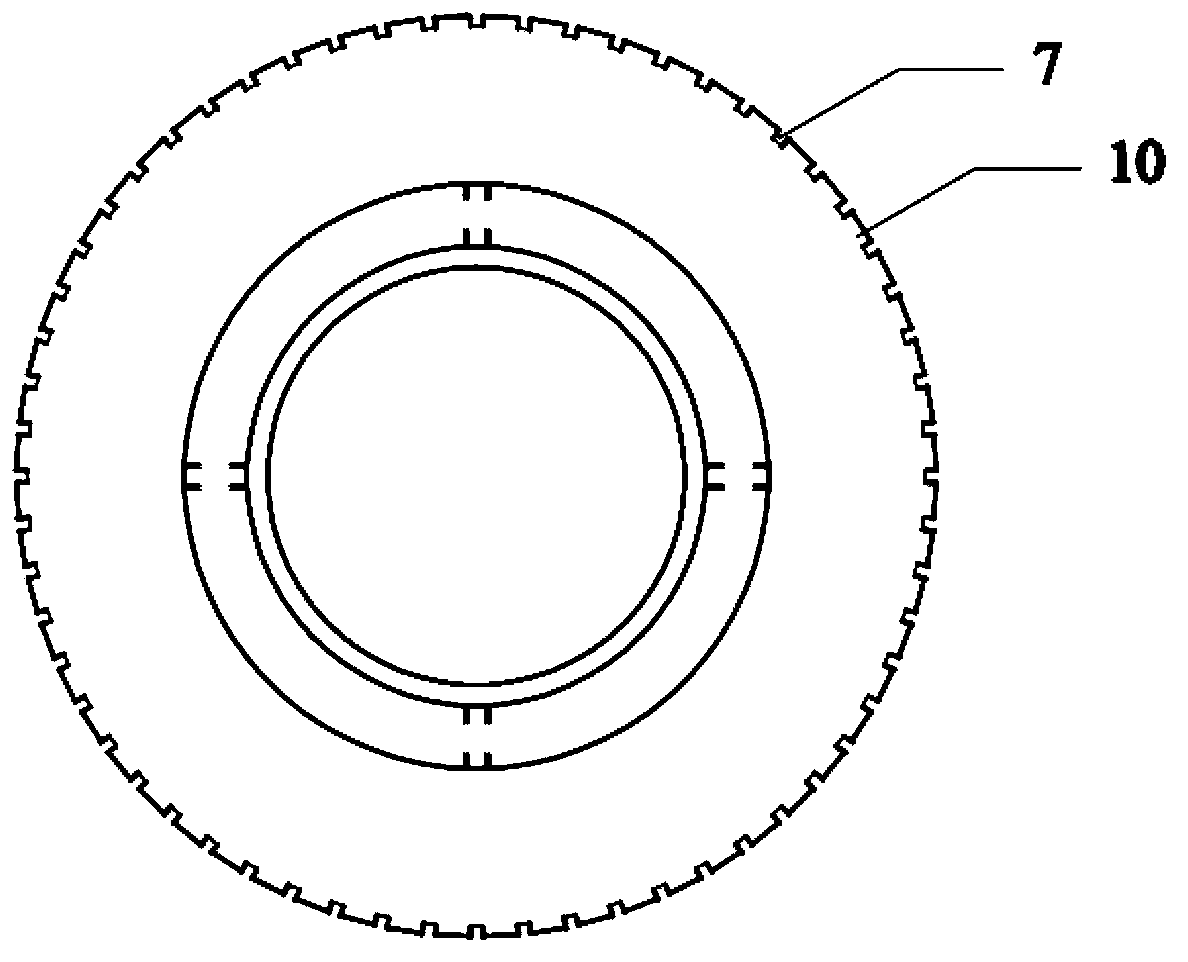

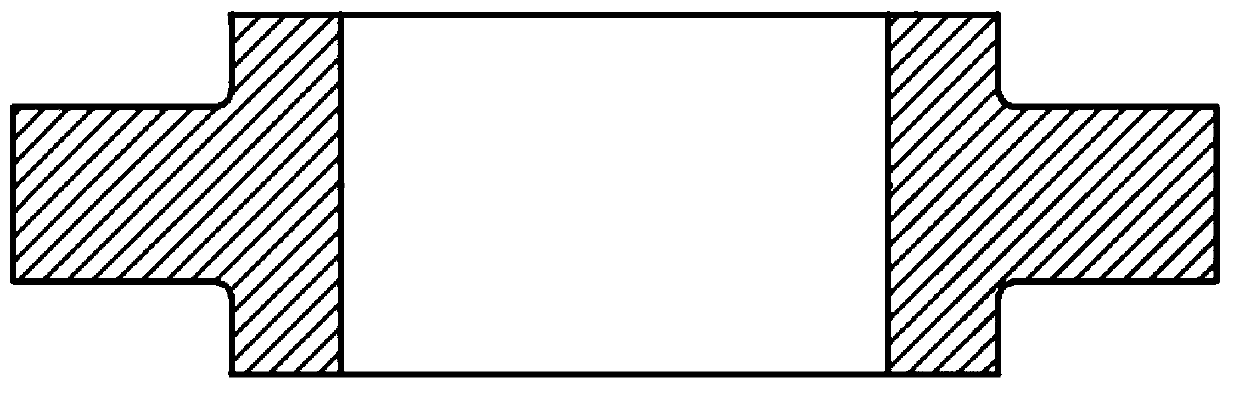

[0034] like figure 1 and figure 2 As shown, a grinding ring 2 is provided on the side wall of the pressure wheel body 1 , and the grinding ring 2 is integrated with the pressure wheel body 1 and is arranged in the middle of the pressure wheel body 1 . Two pinch roller bearing chambers 3 are arranged at the center of the pinch roller body 1, wherein the first pinch roller bearing chamber is formed by extending from the top surface at the center of the pinch roller body to the inside, and the second pinch roller bearing chamber is formed by The bottom surface at the center of the pressure roller body is formed by extending to the inside, and a partition is also provided between the two pressure roller bearing chambers. The upper end and the lower end of the side wall of the pressure roller body are respectively provided with a plurality of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com