Biomass briquette combustion test bed

A molding fuel and combustion test technology, which is used in fuel oil testing, material inspection products, material weighing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

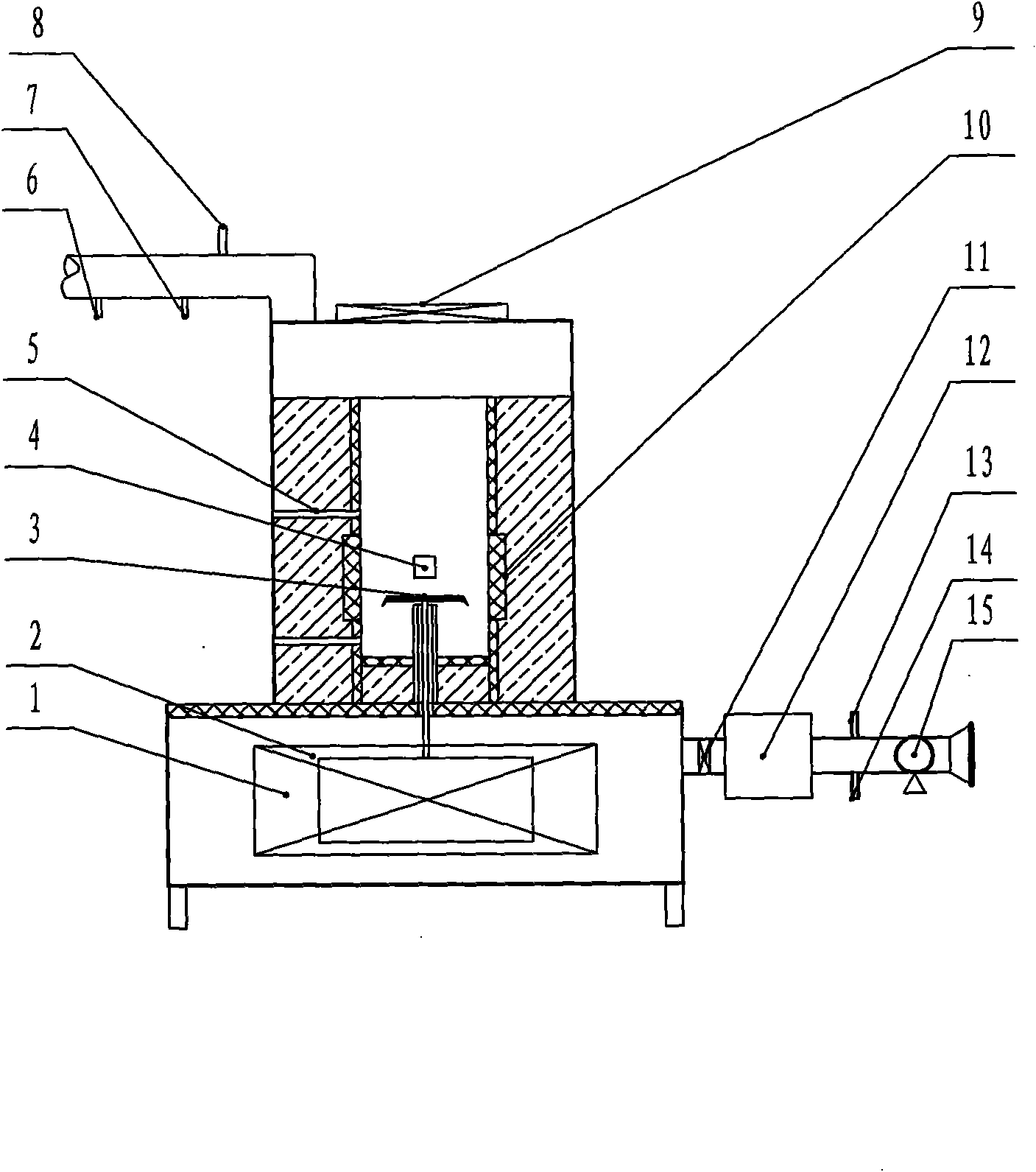

[0014] As shown in the accompanying drawings, the biomass dense molding fuel combustion test bench of the present invention includes a base and a furnace arranged above the base, an electronic balance display device 1 is placed in the base, and an observation port is provided on the front of the base corresponding to the display screen of the electronic balance 2. The display value of the electronic balance can be observed from the observation port. There is a ventilation pipe on one side of the base, and a valve 11 is provided at the end of the ventilation pipe adjacent to the base to control the gas flow rate. An oxygen inlet 13 and a nitrogen inlet 14 are arranged outside the valve 11, and a gas inlet 13 is arranged between the valve 11 and the oxygen inlet 13. The mixing box 12 is provided with a fan 15 at the end of the air duct. The electronic balance stage 3 is placed in the furnace, the furnace is connected to the base, the inner wall of the furnace is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com