Biomass briquette preparation method

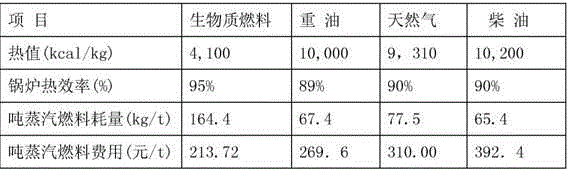

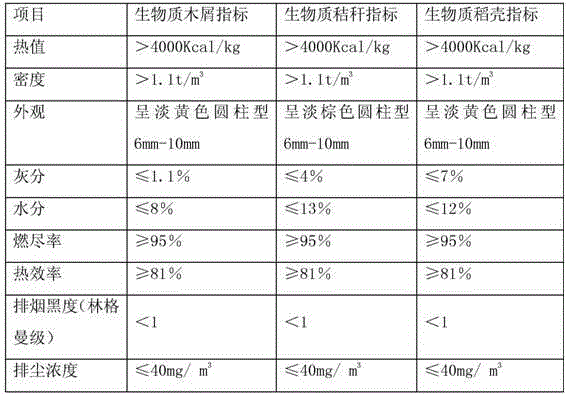

A briquette fuel and biomass technology, applied in the direction of biofuel, waste fuel, etc., can solve the problems of complex process, high cost, single type of raw material, etc., and achieve the effect of simple production process, low cost and high fuel burnout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

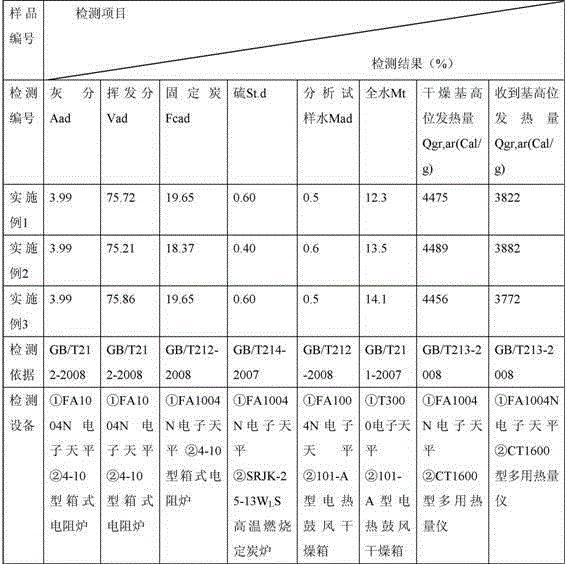

Embodiment 1

[0022] Embodiment 1: Take the raw material of moisture content 50% as example:

[0023] Use a pulverizer to pulverize the biomass raw materials into granules or powders with a diameter of 3mm, sieve and sieve, and sieve the oversized ones for re-crushing or as fuel to the drying equipment, and then transported to the drying equipment by belts Equipment, using a belt with an effective width of 40mm, a raw material thickness of 3mm, and a speed of 350r / min for the feeding belt; using drying equipment to dry the crushed raw materials, the speed of the drying equipment is 700r / min, and the drying temperature in the cylinder is 320 °C, the cylinder wall temperature is 400 °C, so that the moisture content of the raw material is 12%.

[0024] The dried material enters the stone remover through the traction of the fan to remove impurities such as stones, then enters the cyclone separator, and then is sent to the forming step, and the dust enters the bag filter for unified recycling an...

Embodiment 2

[0025] Embodiment 2: Take the raw material of moisture content 60% as example:

[0026] Use a pulverizer to pulverize the biomass raw materials into granules or powders with a diameter of 3mm, sieve and sieve, and sieve the oversized ones for re-crushing or as fuel to the drying equipment, and then transported to the drying equipment by belts Equipment, using a belt with an effective width of 40mm, the thickness of the raw material is 2.5mm, and the speed of the feeding belt is 330r / min; the raw material after crushing is dried with a drying equipment, the speed of the drying equipment is 600r / min, and the drying temperature in the cylinder 330°C, cylinder wall temperature 410°C, so that the moisture content of the raw material is 13%.

[0027] The dried material enters the stone remover through the traction of the fan to remove impurities such as stones, then enters the cyclone separator, and then is sent to the forming step, and the dust enters the bag filter for unified rec...

Embodiment 3

[0028] Embodiment 3: Take the raw material of 70% moisture content as example:

[0029] Use a pulverizer to pulverize the biomass raw materials into granules or powders with a diameter of 3mm, sieve and sieve, and sieve the oversized ones for re-crushing or as fuel to the drying equipment, and then transported to the drying equipment by belts Equipment, using a belt with an effective width of 40mm, the thickness of the raw material is 2mm, and the speed of the feeding belt is 300r / min; the raw material after crushing is dried with a drying equipment, the speed of the drying equipment is 500r / min, and the drying temperature in the cylinder is 340 °C, the cylinder wall temperature is 420 °C, and the moisture content of the raw material is 15%.

[0030] The dried material enters the stone remover through the traction of the fan to remove impurities such as stones, then enters the cyclone separator, and then is sent to the forming step, and the dust enters the bag filter for unifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com