Coal-combustion sulfur-fixing agent and preparation method thereof

A sulfur-fixing agent and coal-fired technology, applied in the field of desulfurization, can solve problems such as poor desulfurization effect, low production efficiency, and heat consumption, and achieve the effects of increasing evaporation, reducing carbon content, and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

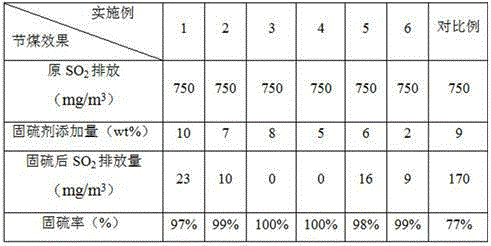

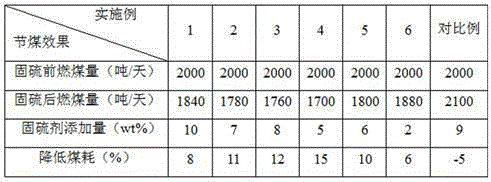

Examples

Embodiment 1

[0025] A sulfur-fixing agent for coal combustion, made of the following raw materials in parts by weight: 50 parts of calcium oxide, 10 parts of zinc slag, 2 parts of copper slag, 4 parts of activator calcium fluoride, and stabilizer Al 2 o 3 1 part, 1 part of calcium sulfoaluminate as activator.

[0026] CaO15wt% in the zinc slag, SiO 2 20wt%, FeO5wt%, Fe 2 o 3 20wt% and ZnO5wt%.

[0027] Fe in the copper slag 2 o 3 20wt%, SiO 2 30wt%, CaO5wt% and Al 2 o 3 2wt%.

[0028] The preparation method of above-mentioned coal-fired sulfur-fixing agent comprises the following steps:

[0029] Add the above-mentioned amount of various raw materials into a ball mill and mix them, and ball-mill them into powders of 0.1-5mm (1.5mm accounts for 10%), and let it stand for 10 hours to get the product sulfur-fixing agent. .

Embodiment 2

[0031] A sulfur-fixing agent for coal combustion, made of the following raw materials in parts by weight: 55 parts of calcium oxide, 12 parts of zinc slag, 2.2 parts of copper slag, 5 parts of activator calcium fluoride, and stabilizer SiO 2 2 parts, 1.1 parts of activator calcium sulfoaluminate.

[0032] CaO11wt% in the zinc slag, SiO 2 23wt%, FeO5wt%, Fe 2 o 3 18wt% and ZnO2wt%.

[0033] Fe in the copper slag 2 o 3 27wt%, SiO 2 35wt%, CaO6wt% and Al 2 o 3 3wt%

[0034] The preparation method of above-mentioned coal-fired sulfur-fixing agent comprises the following steps:

[0035] Add the above-mentioned amount of various raw materials into a ball mill and mix them, and ball-mill them into a powder of 0.1-5mm (1.5mm accounts for 5%), and let it stand for 10 hours to obtain the product sulfur-fixing agent. .

Embodiment 3

[0037] A sulfur-fixing agent for coal combustion, made of the following raw materials in parts by weight: 61 parts of calcium oxide, 15 parts of zinc slag, 2.6 parts of copper slag, 5.2 parts of activator calcium fluoride, and stabilizer SiO 2 1.2 parts and Al 2 o 3 1.2 parts, 1.5 parts of activator calcium sulfoaluminate.

[0038] CaO12wt% in the zinc slag, SiO 2 21wt%, FeO6wt%, Fe 2 o 3 21wt% and ZnO3wt%.

[0039] Fe in the copper slag 2 o 3 30wt%, SiO 2 38wt%, CaO7wt% and Al 2 o 3 2wt%.

[0040] The preparation method of above-mentioned coal-fired sulfur-fixing agent comprises the following steps:

[0041] Add the above-mentioned amount of various raw materials into a ball mill and mix them, and ball-mill them into powders of 0.1-5mm (1.5mm accounts for 10%) powder, and let it stand for 8 hours to obtain the product sulfur-fixing agent. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com