Preparation method of flexible surface enhanced Raman substrate

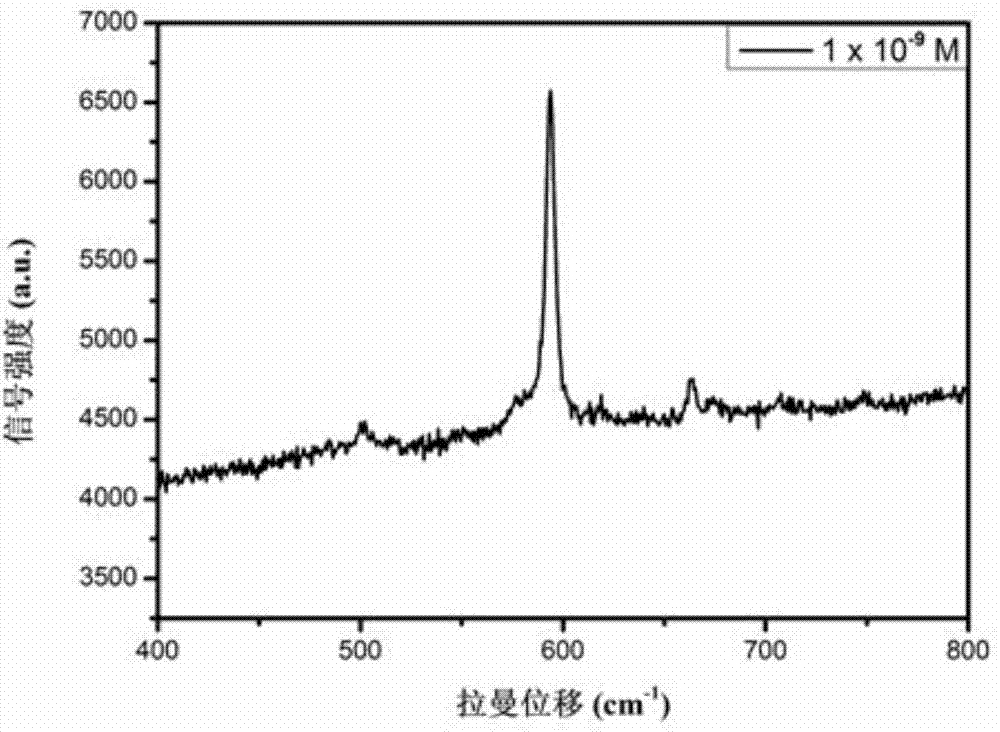

A Raman substrate, flexible surface technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems of uneven signal enhancement effect, easy agglomeration of precious metal particles, large difference in signal intensity, etc. Good consistency and even distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

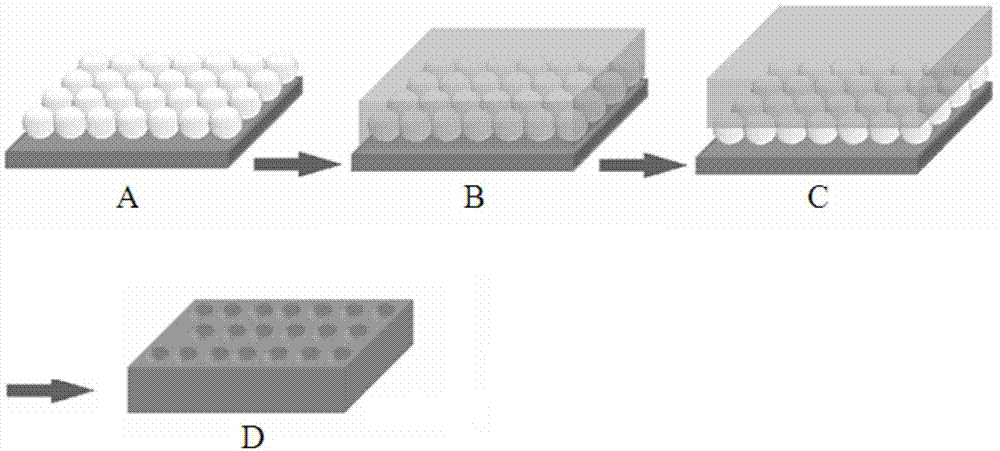

Method used

Image

Examples

Embodiment 1

[0054] (1) Preparation of microsphere template

[0055] a. With 2ml of polystyrene (PS) microsphere suspension (purchased from Alfa Aisha Company, the suspension is a suspension formed by dispersing PS microspheres into deionized water, and the mass percent of microspheres in the suspension is 4 %) was added dropwise to 20ml H + Concentration is in the sulfuric acid of 0.1mol / L, add 1ml concentration again and be the sodium dodecylsulfonate aqueous solution of 0.5wt%, by the surface tension of tensio-active agent sodium dodecylsulfonate, microsphere forms on the sulfuric acid surface uniformly Dense single-layer microsphere film; the particle size of the PS microsphere is about 500nm (standard deviation<3%);

[0056] b. Transfer the microsphere film to the surface of the silicon wafer and dry it at 70°C to obtain a template with PS microspheres deposited on the surface; the specific method for transferring the microsphere film to the surface of the silicon wafer is: hold the ...

Embodiment 2

[0067] (1) Preparation of template

[0068] a. 3ml of silica microsphere suspension (purchased from Sigma, the suspension is made by dispersing silica microspheres in ethanol, the mass percentage of microspheres in the suspension is 2%) is added dropwise to 30ml h + Concentration is in the nitric acid of 1mol / L, add 1ml concentration again and be the sodium dodecylsulfonate aqueous solution of 0.5wt%, by the surface tension of surfactant sodium dodecylsulfonate, the microsphere forms uniform compactness on the surface of nitric acid A single-layer microsphere film; the particle diameter of the silica microsphere is about 300nm (standard deviation<3%);

[0069] b. Transfer the microsphere film to the surface of the silicon wafer, and dry it at 75°C to obtain a template with silica microspheres deposited on the surface; the specific method for transferring the microsphere film to the surface of the silicon wafer is: holding the silicon wafer and holding it Place under the micr...

Embodiment 3

[0078] (1) Preparation of microsphere template

[0079] a. 2ml of aluminum oxide microsphere suspension (purchased from Alfa Aesar, the suspension is formed by dispersing aluminum oxide microspheres in deionized water, the mass percentage of the microspheres in the suspension is 1%) by Add dropwise to 40ml H + Add 2 ml of sodium dodecyl sulfate aqueous solution with a concentration of 0.5 wt% to the hydrochloric acid with a concentration of 5 mol / L, and with the help of the surface tension of the surfactant, the microspheres form a uniform and dense single-layer microsphere film on the surface of the hydrochloric acid; The particle size of the aluminum oxide microspheres is about 750nm (standard deviation <3%);

[0080] b. Transfer the microsphere film to the surface of the silicon wafer, and dry it at 85°C to obtain a template with aluminum oxide microspheres deposited on the surface; the specific method for transferring the microsphere film to the surface of the silicon waf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com