Reaction kettle provided with internal cleaning device

A technology of cleaning device and reaction kettle, which is applied in the field of automatic cleaning of the interior of the reaction kettle and the reaction kettle, can solve the problems of inability to automatically clean and consume a large amount of organic solvent, and achieve the effects of improving the safety of the process, ensuring the continuity and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

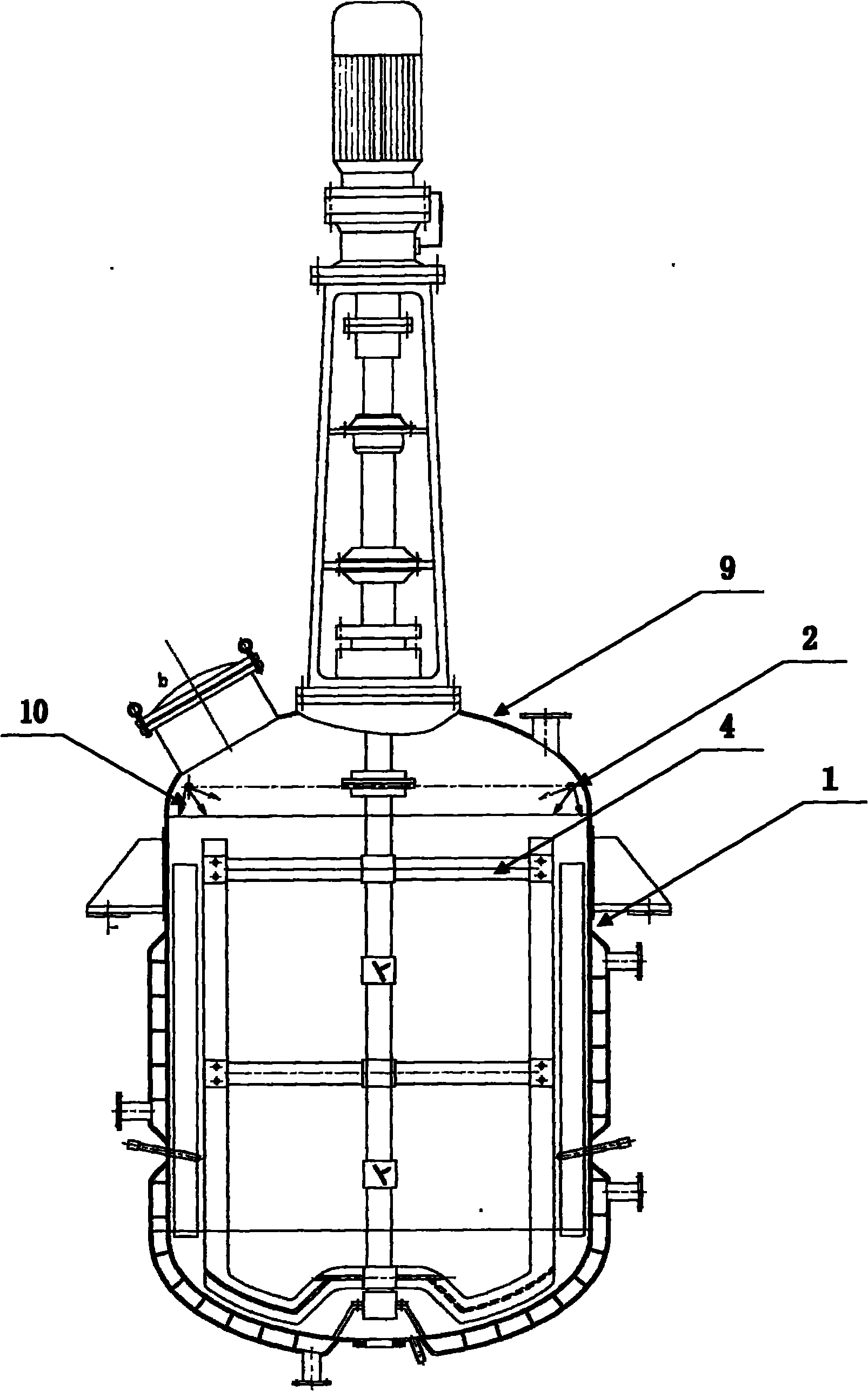

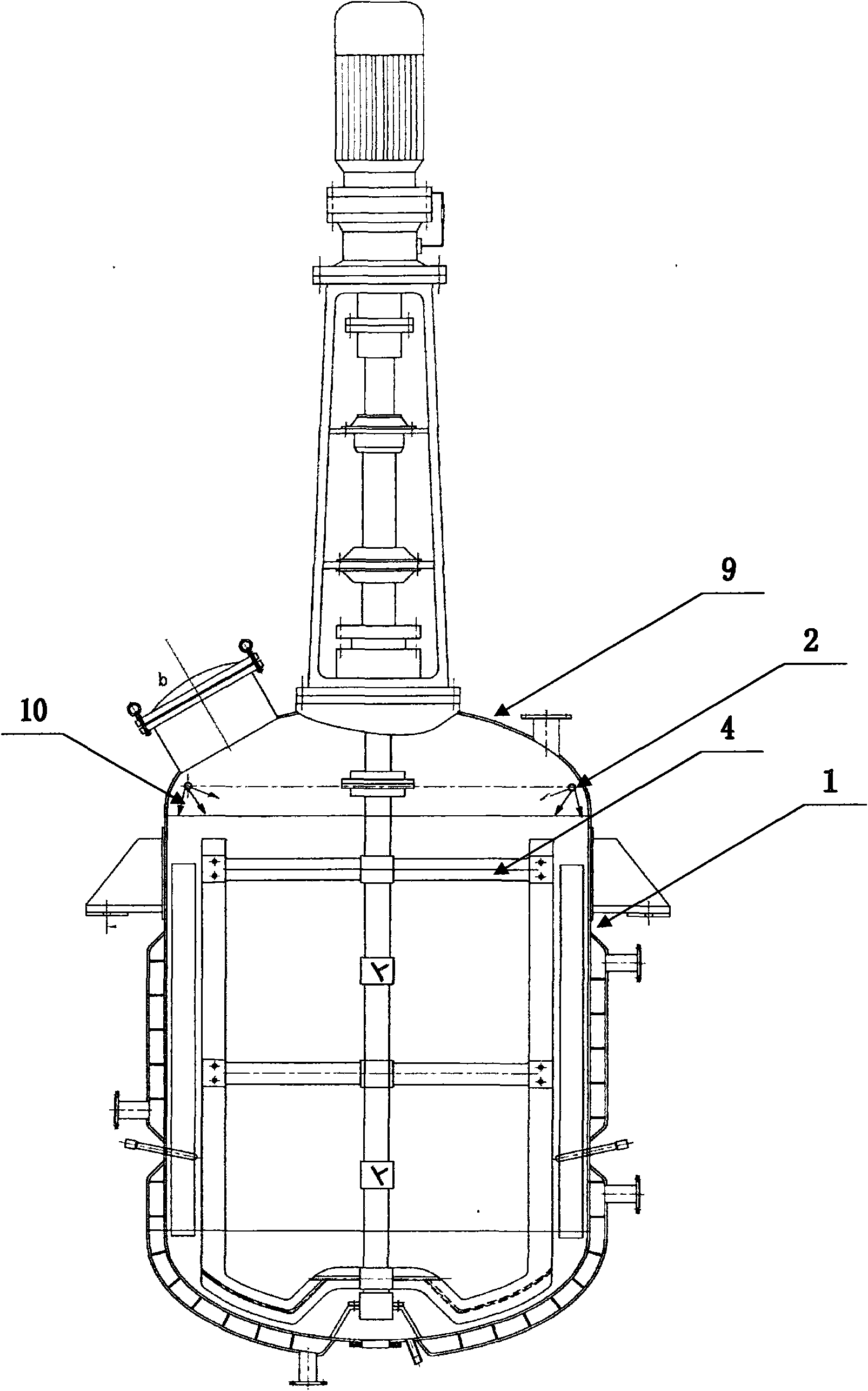

[0008] As shown in accompanying drawing 1, high-pressure spray pipe (2) is arranged under reactor lid (9), above reactor stirring device (4), when needing to clean reactor, high-pressure liquid flow (10) from high-pressure The spray hole (3) on the spray pipe (2) sprays out, impacts the inner wall of the reactor body (1), the reactor stirring device (4), and the reactor stirring device (4) also cooperates with stirring at the same time, so that the inside of the reactor be adequately cleaned;

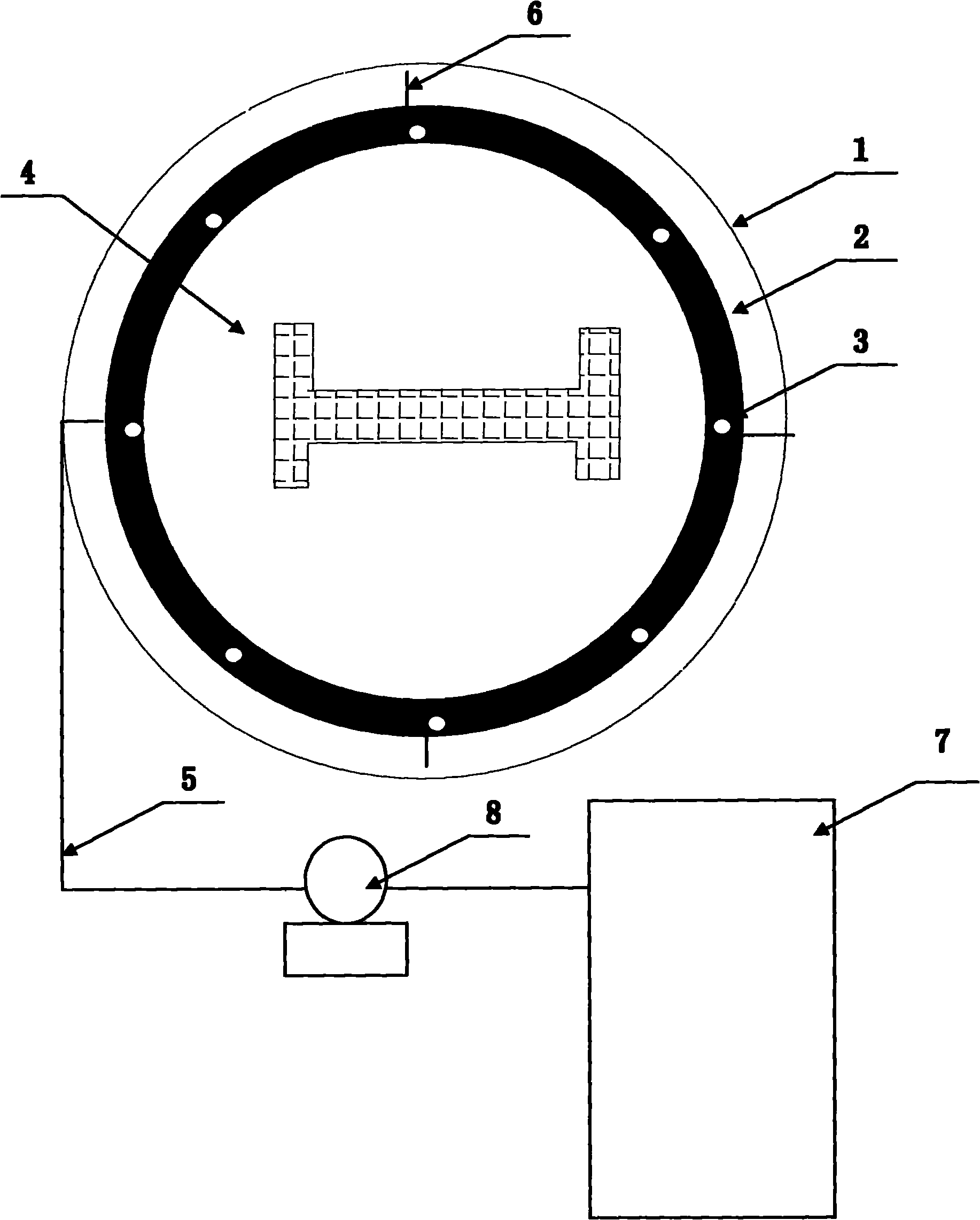

[0009] Such as Figure attached 2 As shown, the high-pressure spray pipe (2) is installed on the bracket (6), the spray hole (3) is opened on the top, and the cleaning pump (8) is connected through the cleaning agent pipeline (5), and the cleaning pump (8) is connected to the cleaning agent tank (7).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com