Developed-mesopore active carbon for super capacitor electrode and preparation method thereof

A supercapacitor and activated carbon technology, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, chemical instruments and methods, etc., can solve problems such as contribution without further research, and achieve high mesopore occupancy rate and pore structure Reasonable and wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Mechanically pulverize the needle coke with a toothed pulverizer, pass through the 14-mesh and 20-mesh screens continuously, take the intermediate materials of the 14-mesh and 20-mesh screens, and place them in a vacuum furnace for carbonization. The vacuum furnace is first evacuated to 10Pa, then the temperature is raised to 350°C at 5°C / min, the temperature is kept constant for 1h, and the temperature is naturally lowered at the end of the heat preservation.

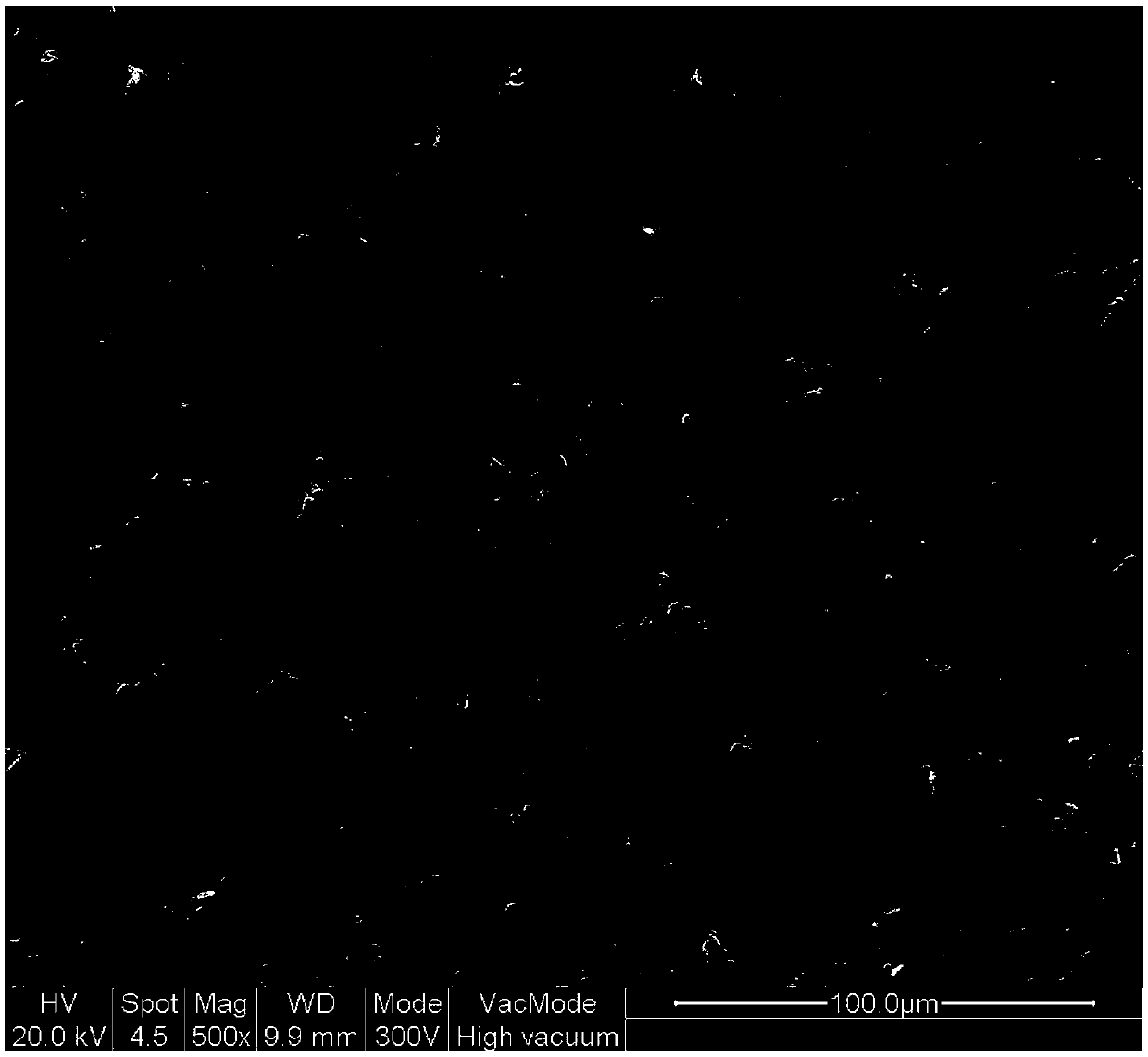

[0038] 2. Take the carbonized material in step 1 and put it in the activation furnace, replace the air in the furnace with nitrogen for 10 minutes, the nitrogen flow rate is 10ml / min, then the activation furnace is heated up to 750°C at 5°C / min, and activated with water vapor, the water vapor The flow rate is 10ml / min, and the activation time is 3h. The temperature of the activation furnace is naturally lowered, and the output material is pulverized by a fluidized bed jet mill, with a median particle size of ...

Embodiment 2

[0043] The difference from Example 1 is that this example chooses coal tar pitch coke as the raw material. Keep the temperature at 350°C for 3 hours in a vacuum furnace, and cool down naturally after the heat preservation. Subsequent activation and powder treatment process are the same as in Example 1.

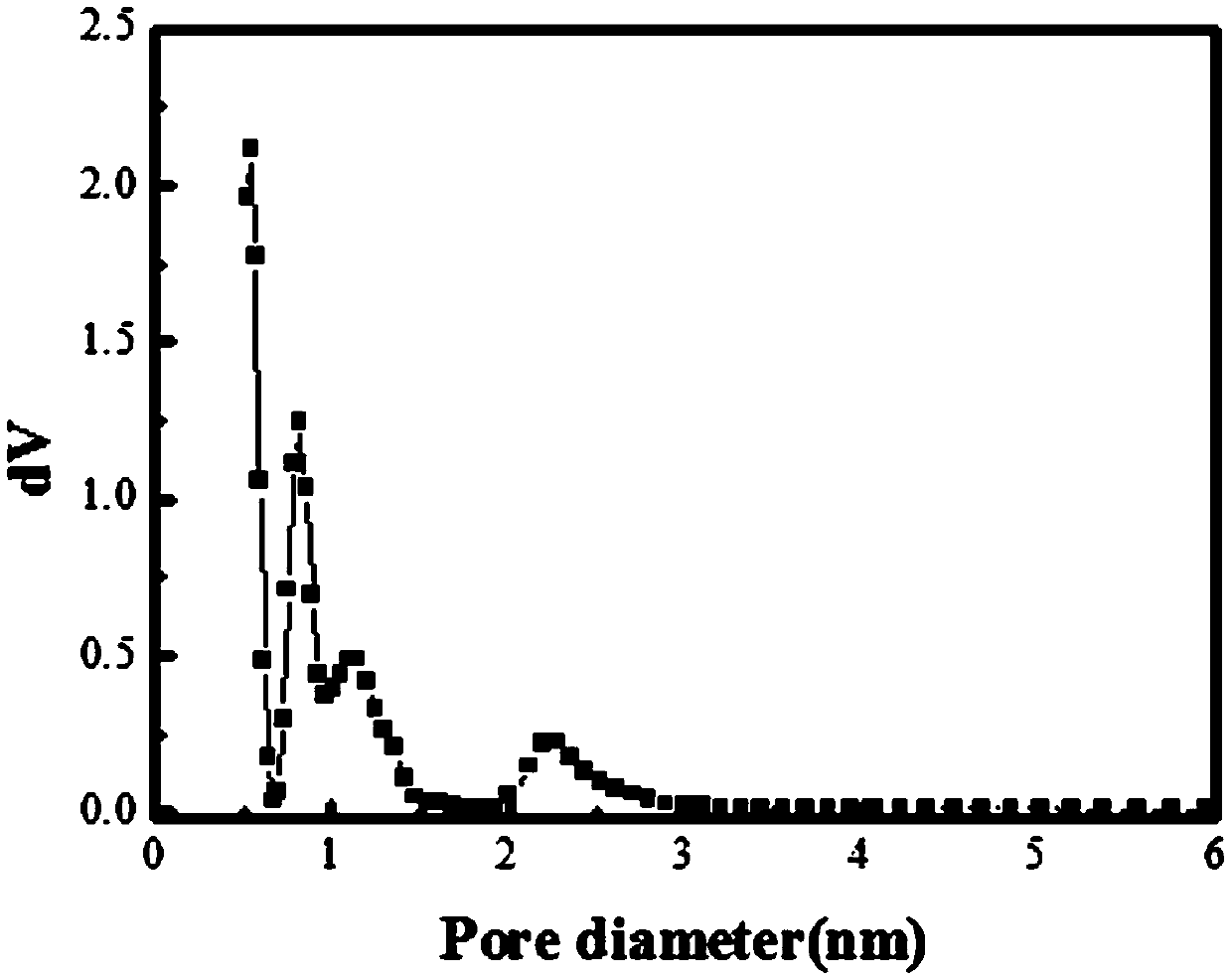

[0044] The low-temperature nitrogen adsorption test shows that the specific surface area of the activated carbon is 2050m 2 / g, the proportion of mesopores with a pore diameter of 2 to 3 nm is 24%. The supercapacitor activated carbon electrode material has a specific capacitance of 116F / g at a discharge current density of 50mA / g.

Embodiment 3

[0046] 1. Mechanically pulverize the mesophase pitch with a press mill pulverizer, pass through 20-mesh and 30-mesh screens continuously, take the intermediate material of 20-mesh and 30-mesh screens, and place them in a vacuum furnace for carbonization. The vacuum furnace is first evacuated to 10 -1 Pa, then raise the temperature to 550°C at 5°C / min, keep the temperature constant for 3h, and cool down naturally at the end of the heat preservation.

[0047] 2. Take the carbonized material in step 1 and put it in the activation furnace, and replace the air in the furnace with nitrogen for 10 minutes, the nitrogen flow rate is 10ml / min, then the activation furnace is heated up to 850°C at 5°C / min, activated with water vapor, and the water vapor The flow rate is 10ml / min, and the activation time is 5h. The temperature of the activation furnace is naturally lowered, and the output material is pulverized by a fluidized bed jet mill, with a median particle size of D50=13 μm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com