Fluorinated graphene with large surface area and high thermal stability and preparation method thereof

A technology of fluorinated graphene and high thermal stability, which is applied in the direction of graphene, chemical instruments and methods, carbon fluoride, etc., can solve the problems of low thermal stability and low real specific surface area of fluorinated graphene, and achieve specific surface area Improvement, easy thermal stability, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

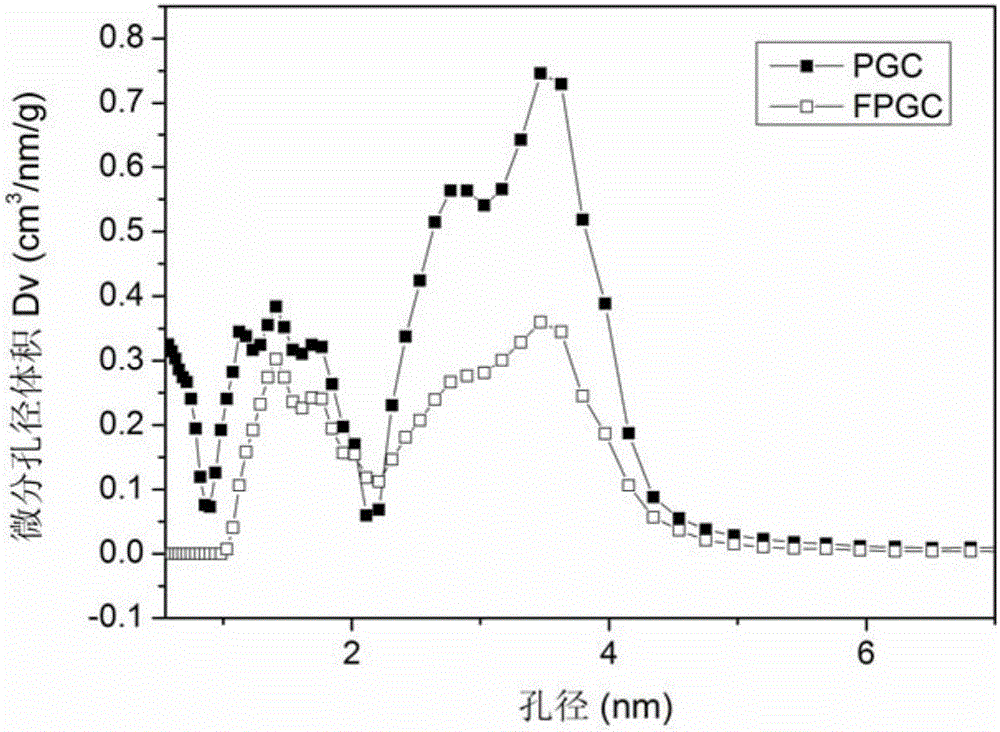

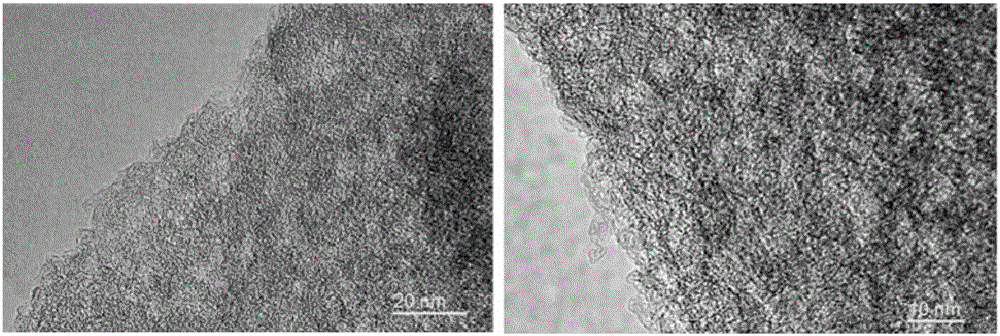

[0030] Mix graphene and potassium hydroxide uniformly at a ratio of 1:4, and then treat the mixture at 600°C for 5 hours under a nitrogen atmosphere to obtain activated graphene; place the activated graphene in a closed vacuum reactor, and replace the reactor with nitrogen Vacuum the air in the chamber three times, then fill it with a mixture of fluorine and nitrogen, and control the initial partial pressure of fluorine to 30KPa, then raise the temperature to 30°C at a heating rate of 3°C / min and keep it warm for 60 minutes, then cool naturally The fluorinated graphene is obtained at room temperature.

[0031] The fluorine content in the fluorinated graphene is 20%, and the specific surface area is 1800m 2 / g, the peak weight loss temperature is 560°C.

Embodiment 2

[0033] Mix graphene and potassium hydroxide uniformly at a ratio of 1:7, and then treat the mixture at 800°C for 1 hour under a nitrogen atmosphere to obtain activated graphene; place the activated graphene in a closed vacuum reactor and replace the reaction with argon Vacuum the air in the vessel three times, then fill it with a mixture of fluorine and argon, and control the initial partial pressure of fluorine to 40KPa, then raise the temperature to 150°C at a heating rate of 10°C / min and keep it warm for 150 minutes. Cool naturally to room temperature to obtain fluorinated graphene.

[0034] The fluorine content in the fluorinated graphene is 34%, and the specific surface area is 1600m 2 / g, the peak weight loss temperature is 565°C.

Embodiment 3

[0036]Mix graphene, magnesium citrate and potassium citrate uniformly at a ratio of 1:4:4, and then treat the mixture at 800°C for 0.5h under nitrogen and argon atmosphere to obtain activated graphene; place the activated graphene in a closed In the vacuum reactor, replace the air in the reactor with argon for three times, then evacuate it, then fill it with a mixture of fluorine and argon, and control the initial partial pressure of fluorine to 50KPa, and then increase the temperature at a rate of 10°C / min. Raise the temperature to 100°C and keep it warm for 300 minutes, then cool naturally to room temperature to obtain graphene fluoride.

[0037] The fluorine content in the fluorinated graphene is 43%, and the specific surface area is 1600m 2 / g, the peak weight loss temperature is 575°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com