Method for purifying hafnium tetrachloride

A purification method and technology of hafnium tetrachloride, applied in the field of purification of hafnium tetrachloride, can solve the problems of harsh production conditions, complicated process operation, low production efficiency, etc. Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

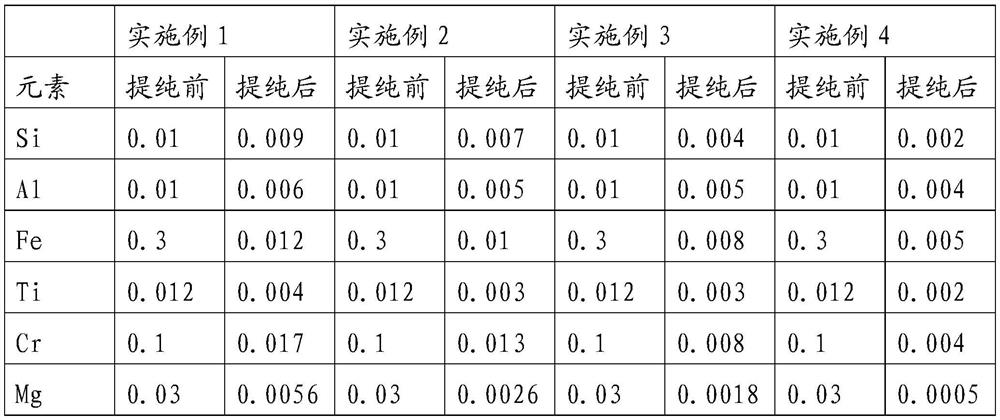

Examples

Embodiment 1

[0033] A method for purifying hafnium tetrachloride, comprising the steps of:

[0034] Step 1. Take 5000kg of crude hafnium tetrachloride with high impurity content and add it to the reaction tank, and simultaneously turn on the stirrer and heating components of the reaction tank.

[0035] Step 2, 1253kg of KCl-NaCl mixed molten salt is added to the reaction tank, wherein sodium chloride is 550kg, and potassium chloride is 700kg; the particle size of the sodium chloride and potassium chloride is 60-100 mesh, and in the mixed molten salt Contains 3kg of zirconium powder.

[0036] Step 3. Raise the temperature of the reaction tank to 270°C-280°C, and open the exhaust valve.

[0037] Step 4. Raise the temperature of the reaction tank to 580°C-590°C, and collect HfCl with a condensation trap 4 , the coagulation time is 30min-45min.

[0038] Step 5. After reducing the temperature of the double salt in the reaction tank to below 300°C, add 5000kg of crude hafnium tetrachloride wi...

Embodiment 2

[0041] A method for purifying hafnium tetrachloride, comprising the steps of:

[0042] Step 1. Take 5500 kg of crude hafnium tetrachloride with high impurity content and add it to the reaction tank, and simultaneously turn on the stirrer and heating components of the reaction tank.

[0043] Step 2, 1378.5kg of KCl-NaCl mixed molten salt is added to the reaction tank, wherein the sodium chloride is 600kg, and the potassium chloride is 775kg; the particle size of the sodium chloride and potassium chloride is 60-100 mesh, and the mixed molten salt Contains 3.5kg of zirconium powder.

[0044] Step 3. Raise the temperature of the reaction tank to 280°C-300°C, and open the exhaust valve.

[0045] Step 4. Raise the temperature of the reaction tank to 590°C-600°C, and collect HfCl with a condensation trap 4 , the coagulation time is 30min-45min.

[0046] Step 5. After reducing the temperature of the double salt in the reaction tank to below 300°C, add 5500kg of crude hafnium tetrac...

Embodiment 3

[0049] A method for purifying hafnium tetrachloride, comprising the steps of:

[0050] Step 1. Take 6000 kg of crude hafnium tetrachloride with high impurity content and add it to the reaction tank, and simultaneously turn on the stirrer and heating components of the reaction tank.

[0051] Step 2, 1505kg of KCl-NaCl mixed molten salt is added to the reaction tank, wherein sodium chloride is 680kg, and potassium chloride is 820kg; the particle size of the sodium chloride and potassium chloride is 60-100 mesh, and in the mixed molten salt Contains 5kg of zirconium powder.

[0052] Step 3. Raise the temperature of the reaction tank to 300°C-320°C, and open the exhaust valve.

[0053] Step 4. Raise the temperature of the reaction tank to 600°C-610°C, and collect HfCl with a condensation trap 4 , The coagulation time is 35min-50min.

[0054] Step 5. After reducing the temperature of the double salt in the reaction tank to below 300°C, add 6000kg of crude hafnium tetrachloride w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com