Risk degree grading method for fine chemical production process safety evaluation

A technology for production process and safety assessment, applied in the direction of chemical process analysis/design, etc., can solve the problems of economic losses and exaggerated risks of chemical enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

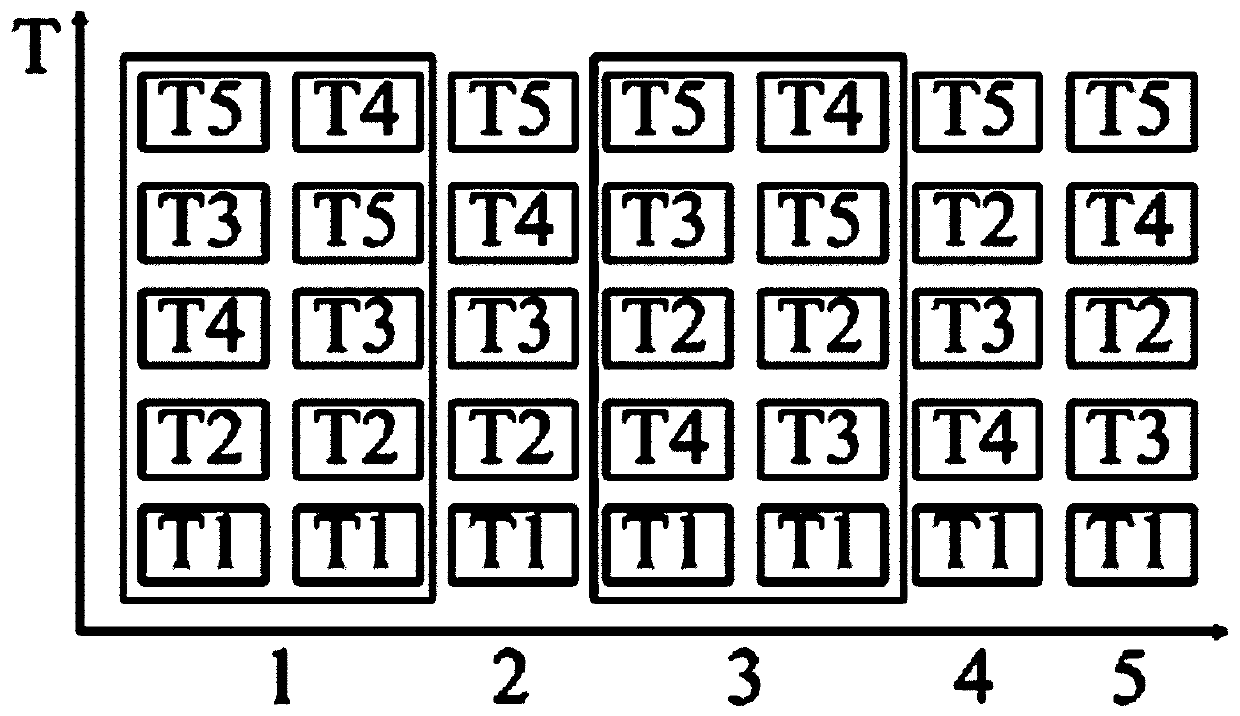

Method used

Image

Examples

Embodiment

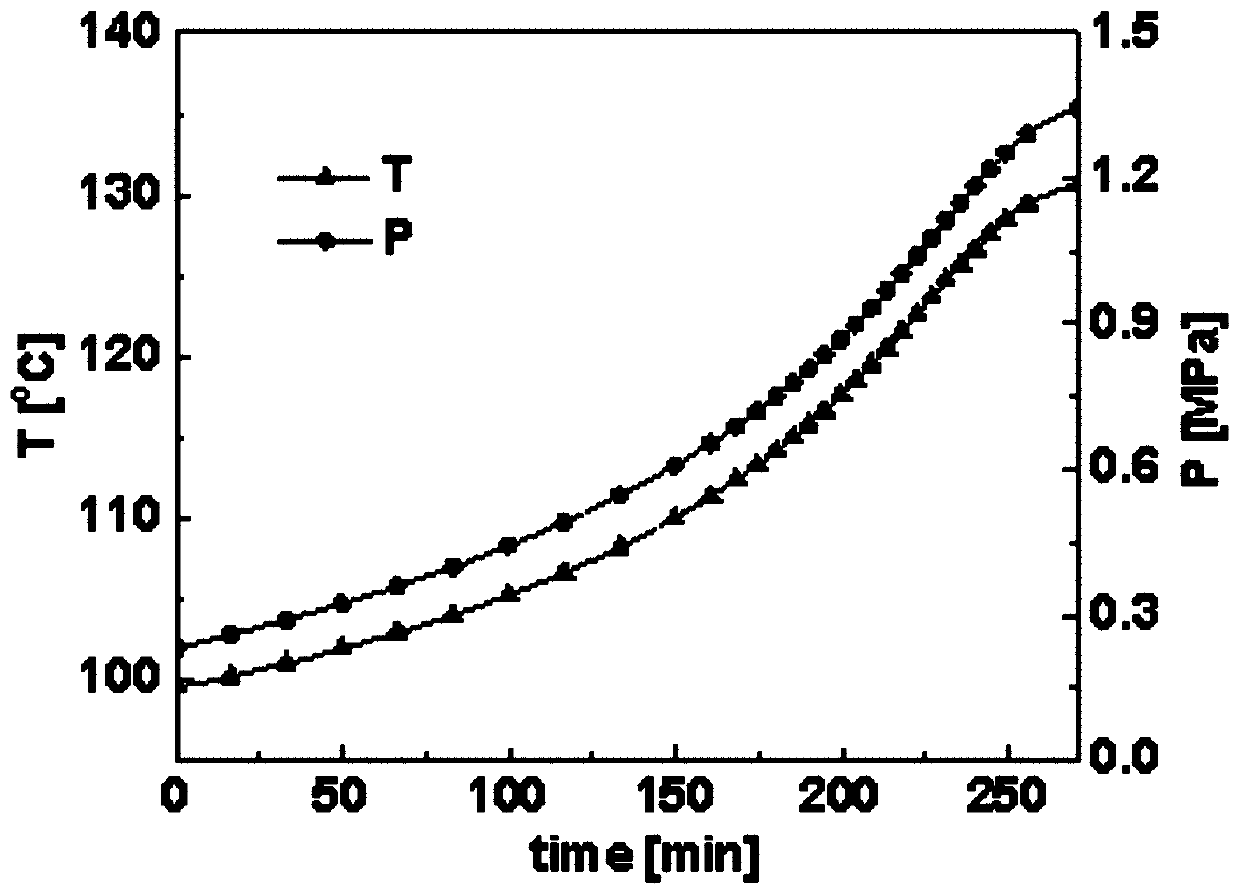

[0105] 1. Get parameters

[0106] 1-1) Determine the assessment object to be the process safety assessment of tert-butyl peracetic acid (TBPA) synthesis process under alkaline reaction conditions.

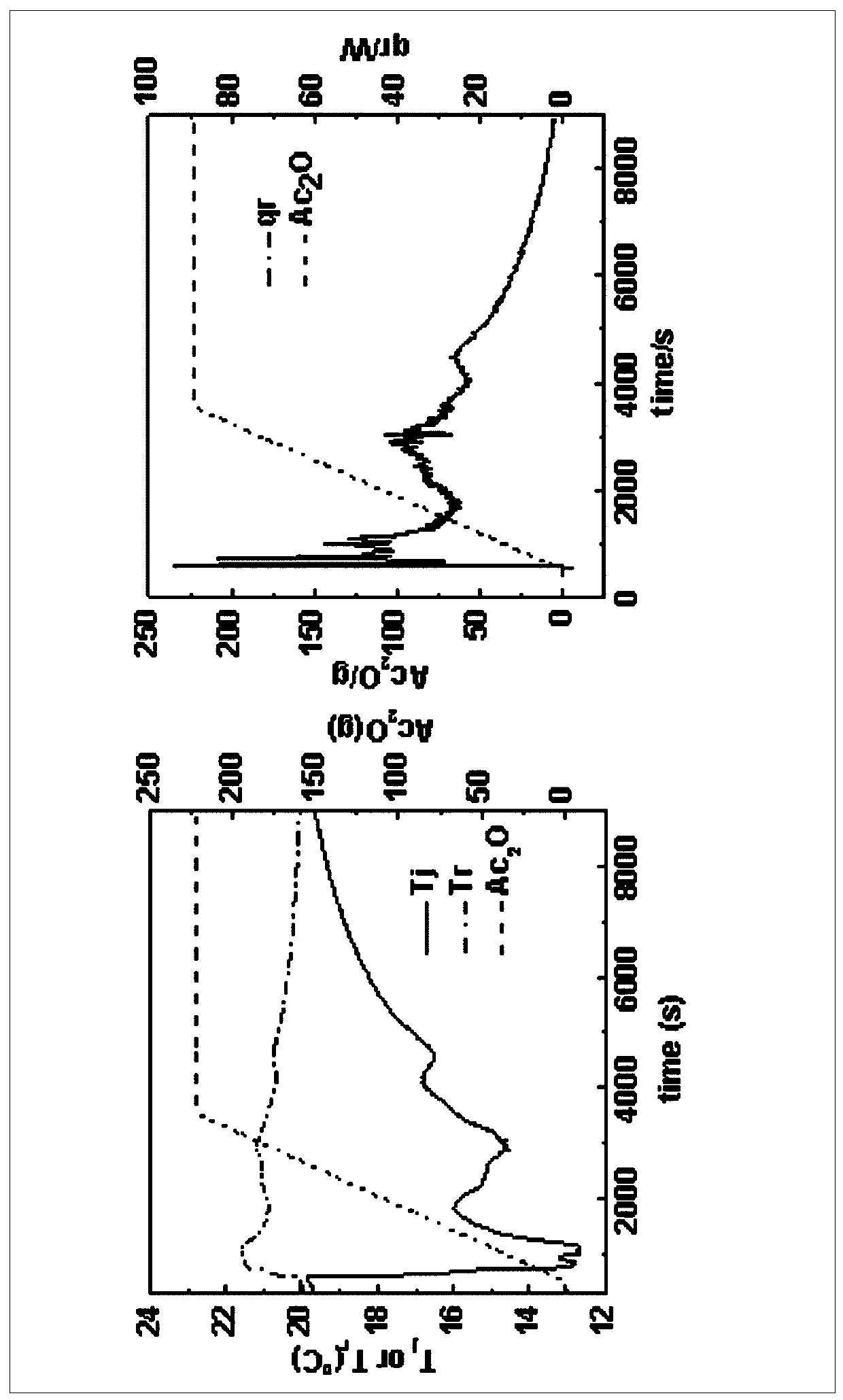

[0107] In the actual production process, tert-butyl hydroperoxide (TBHP) reacts with sodium hydroxide to form an organic salt solution of tert-butyl hydroperoxide, then adds acetic anhydride (Ac2O), turns on the agitator, and proceeds with the organic salt The reaction produces TBPA. During the reaction, the reaction temperature was controlled with frozen brine, and the reaction temperature was 20°C. The process is a semi-batch operation, and the reaction equation is as follows:

[0108] .

[0109] 1-2) Conduct TBPA synthesis isothermal calorimetry experiment;

[0110] The experimental instrument used is a reaction calorimeter;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com