Round steel cutter

A cutting machine and round steel technology, which is applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve the problems of unsatisfactory shearing effect, large section slope, and cutting machine wear, etc., and achieve improvement Process safety, large shear force, and the effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

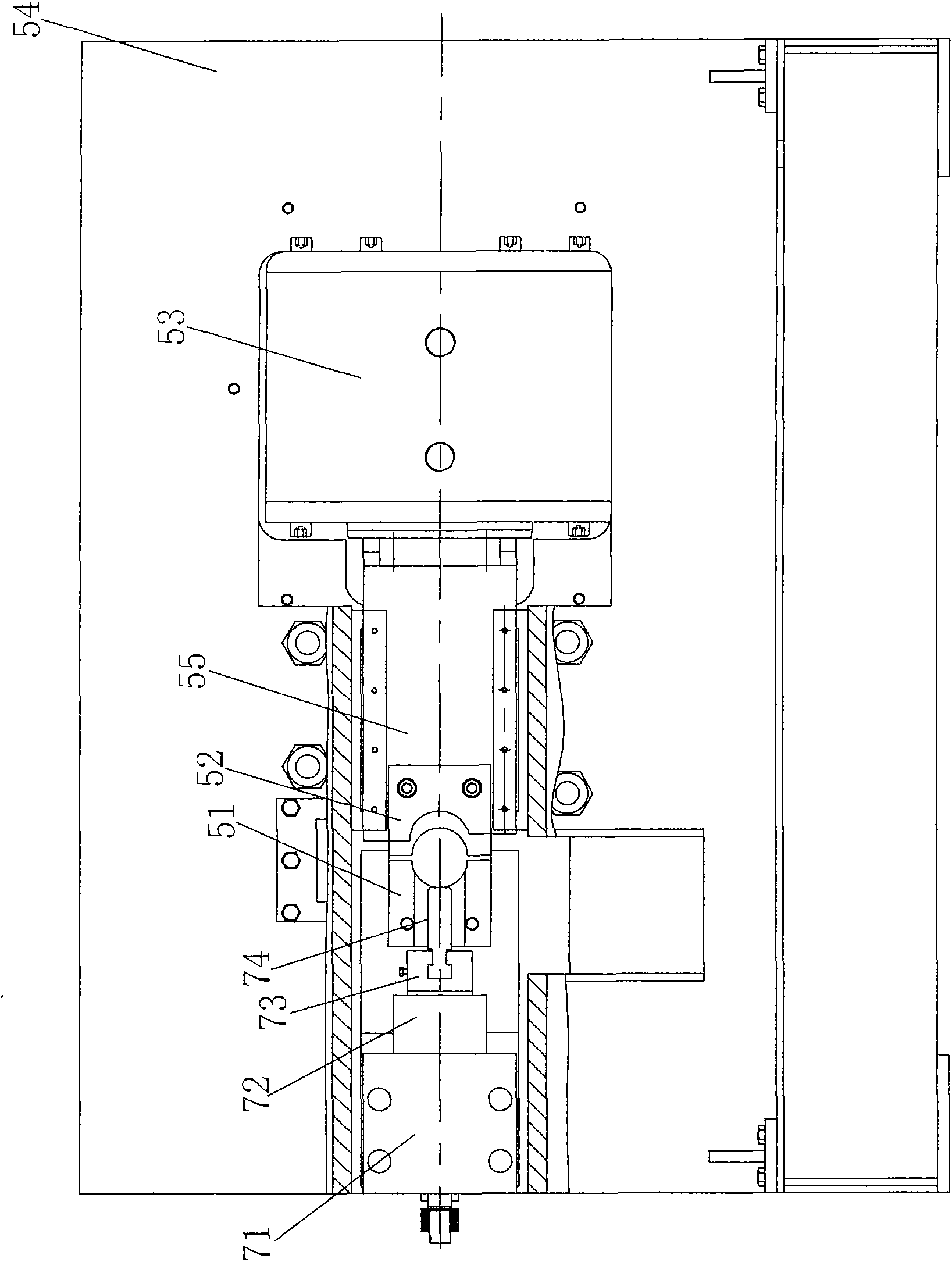

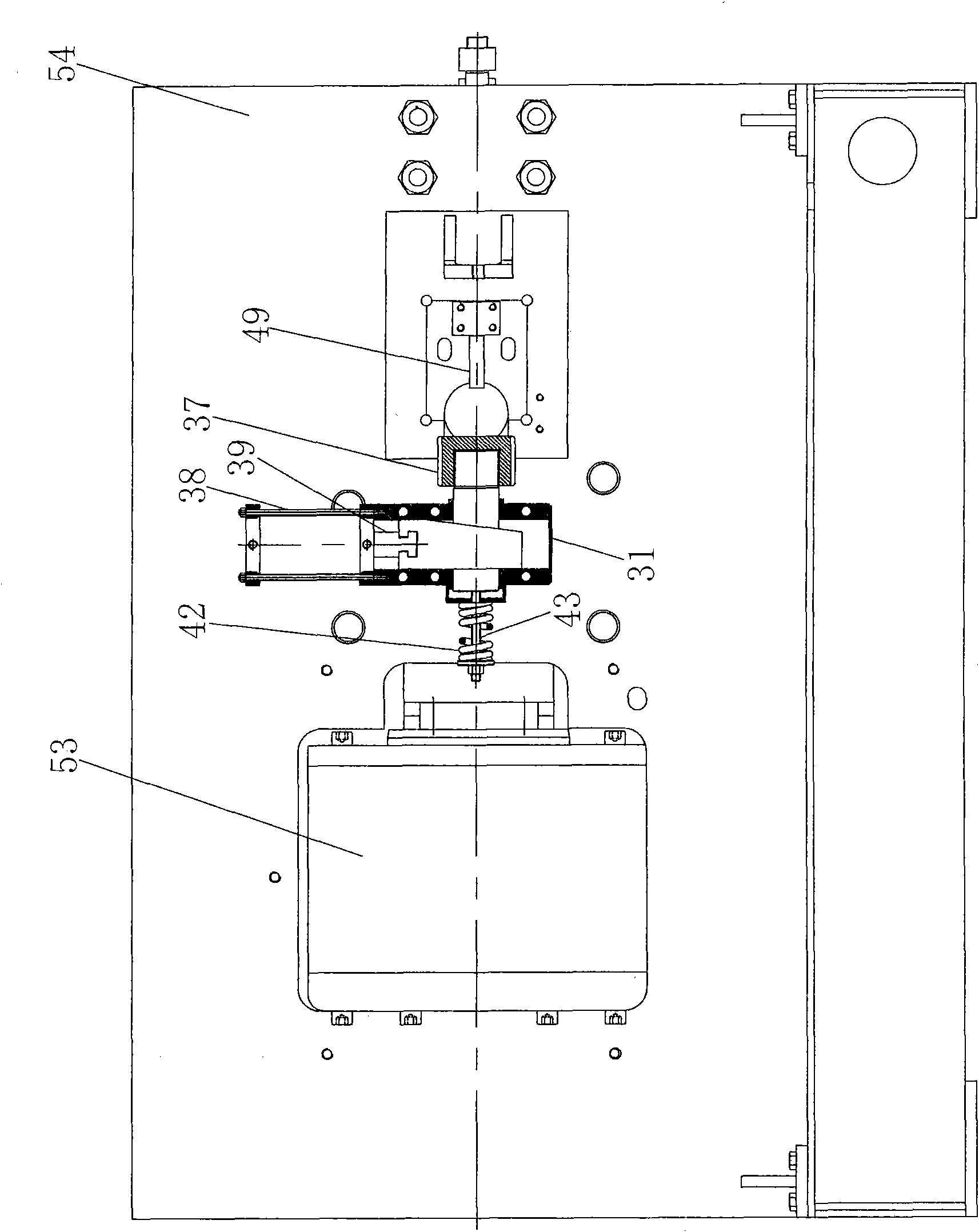

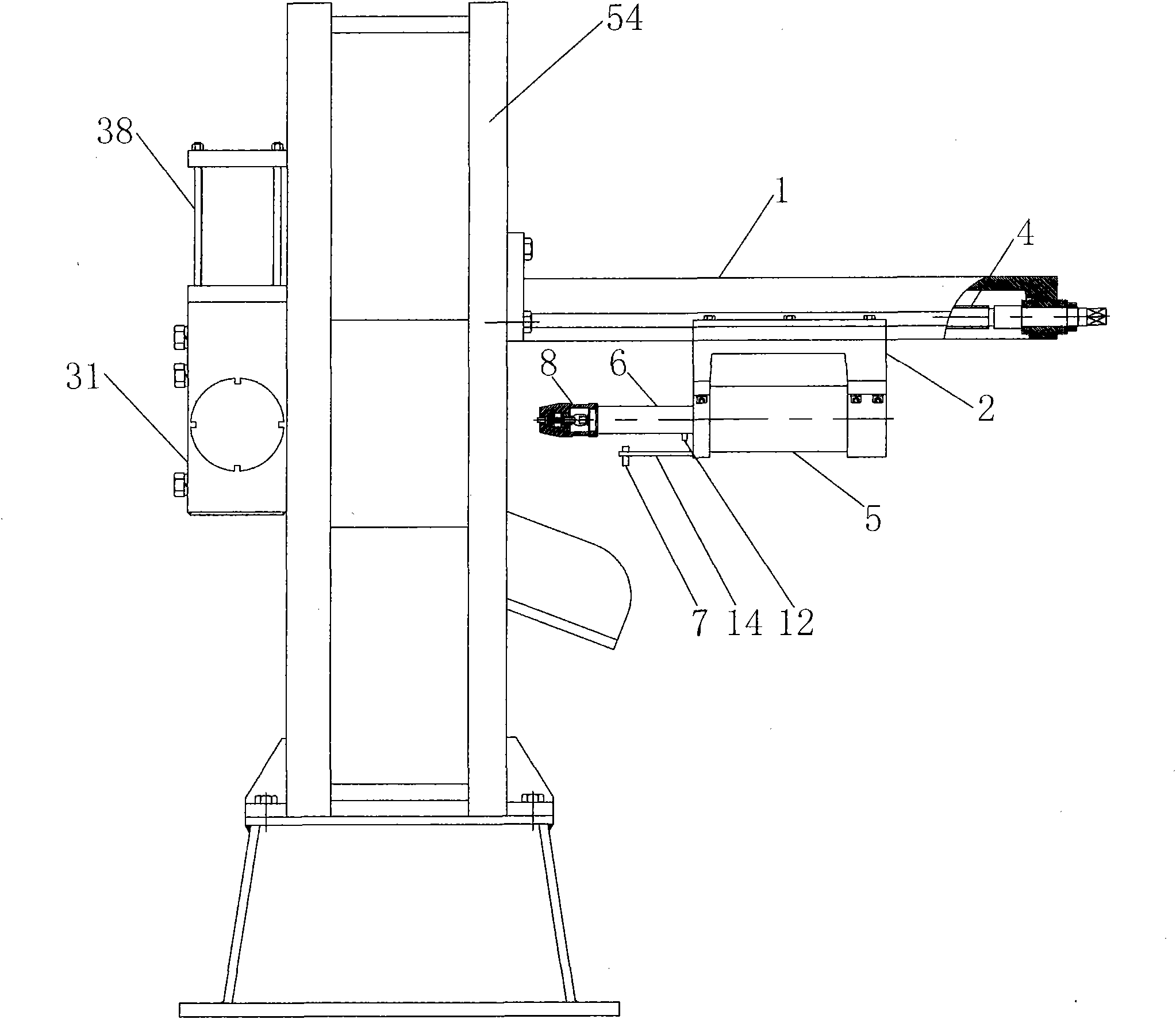

[0034] Embodiment: a kind of round steel cutting machine, as Figure 1-3 As shown, it includes a fixed knife 51, a moving knife 52, and a main oil cylinder 53. The fixed knife 51 is fixed at the cutting opening of the cutting machine body 54, and the moving knife 52 is installed on a moving knife seat 55. The piston rod is connected to each other, and the material inlet and the outlet of the machine body 54 are respectively provided with a pressing device and a material supporting device for clamping the round steel during shearing. The semi-circular hole groove of the round steel is placed, and the moving knife 52 and the fixed knife 51 are staggered. After the round steel is fed into the semi-circular hole groove of the fixed knife 51 through the feeder, the pressing device and the supporting device will clamp the round steel. The movable knife 51 slides on the body 54 under the action of the main oil cylinder 53 to cut material.

[0035] Such as Figure 4 , Figure 5 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com